Custom Online Metal Casting Manufacturing Service

Our Custom Online Metal Casting Manufacturing Service offers rapid prototyping, precision casting, and comprehensive post-processing for various metals. We provide flexible design options, including aluminum, zinc, and steel, ensuring high-quality, tailored solutions for your specific manufacturing needs.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

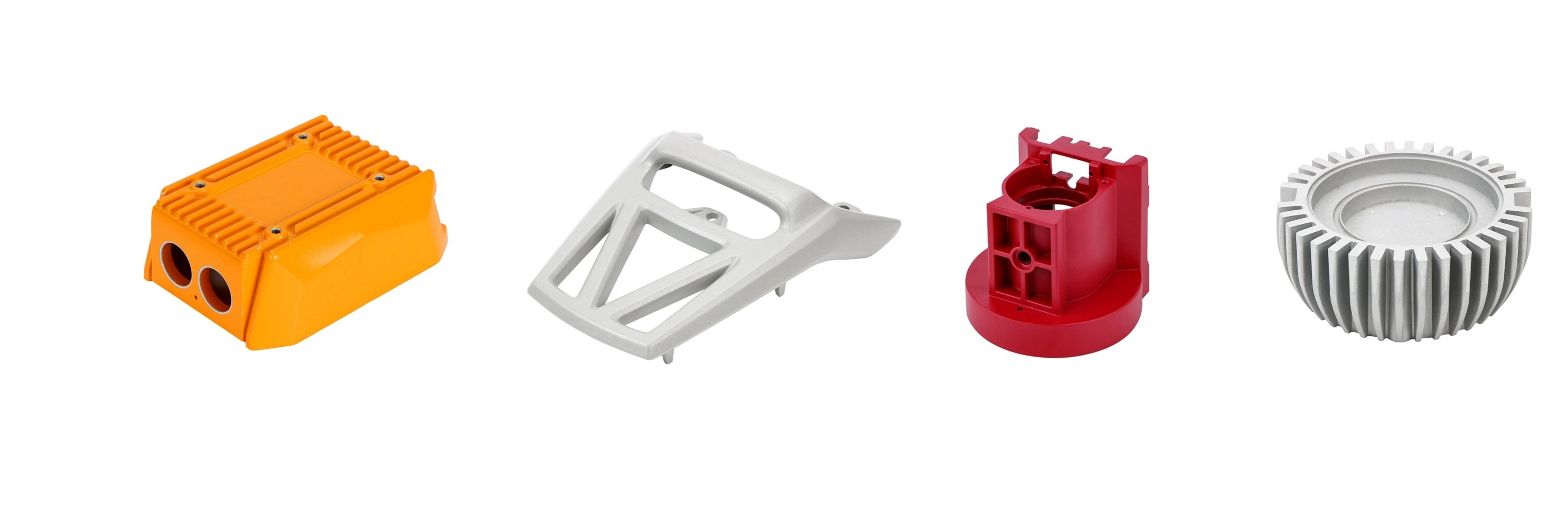

Our Metal Casting Manufacturing Solutions

Our Metal Casting Manufacturing Service delivers precision casting solutions for various industries. We specialize in aluminum, zinc, and copper alloys, offering rapid prototyping, advanced post-processing, and custom designs to meet your specific product requirements, ensuring high quality and reliability.

Metal Casting Design and Manufacturing

Our Metal Casting Solutions offer end-to-end services, including expert design, engineering, rapid prototyping, low-volume manufacturing, and mass production. We provide a one-stop solution, ensuring high-quality, cost-effective, customized casting parts tailored to your specific requirements.

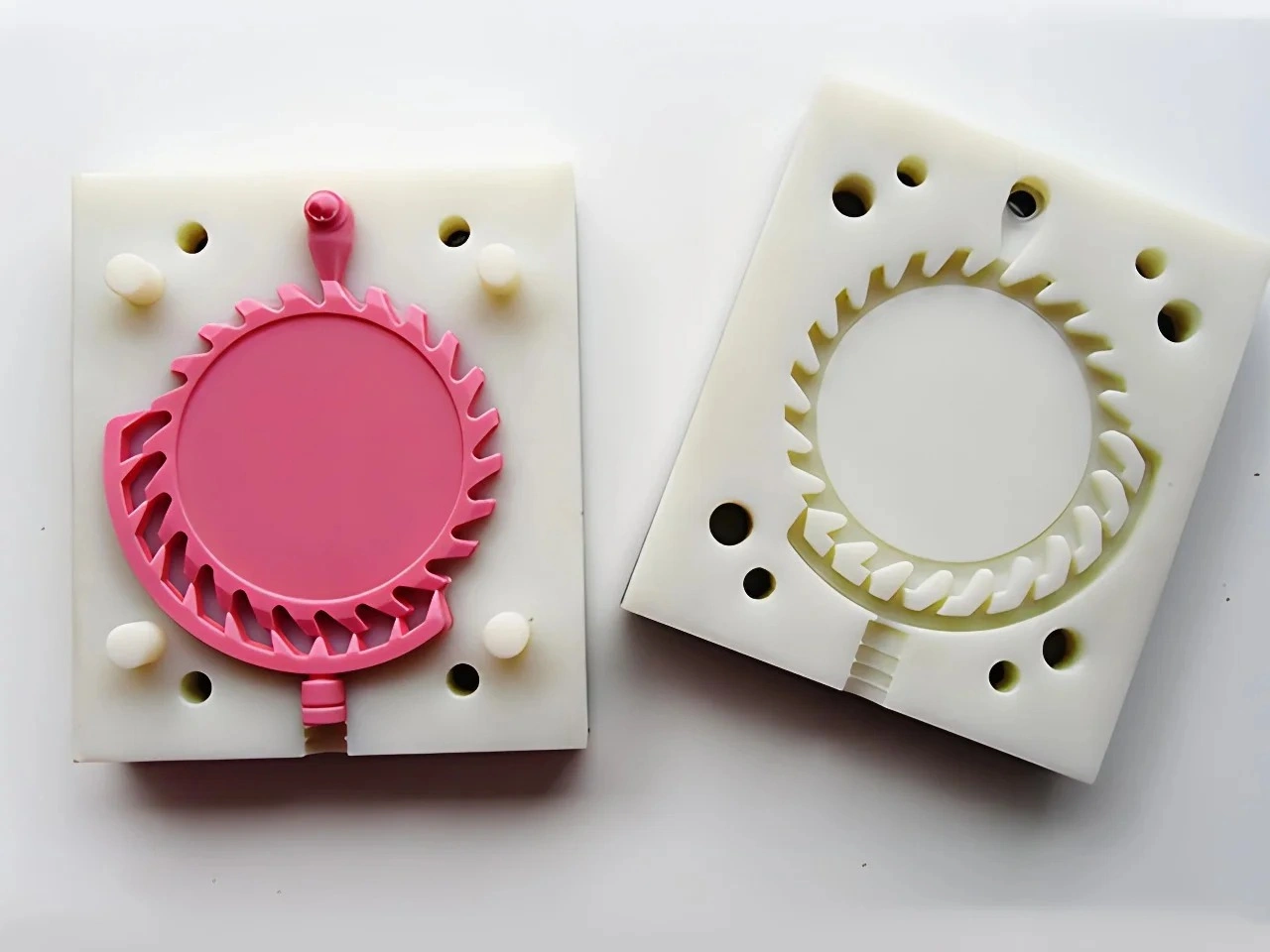

Rapid Prototyping Service

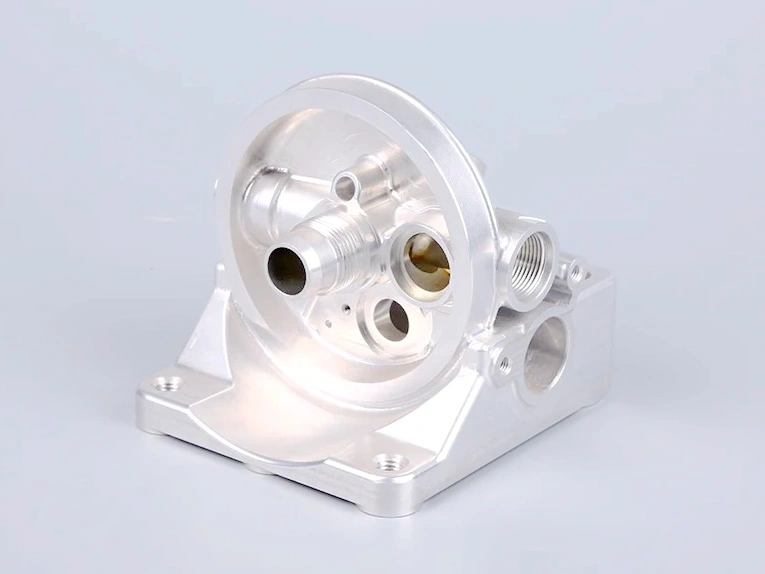

Our Rapid Prototyping Service offers fast, cost-effective solutions using CNC machining, 3D printing, urethane casting, and sand casting. We provide high-quality prototypes with precise designs, enabling quick testing, iteration, and refinement to meet your specific manufacturing needs.

Post Process For Die Castings

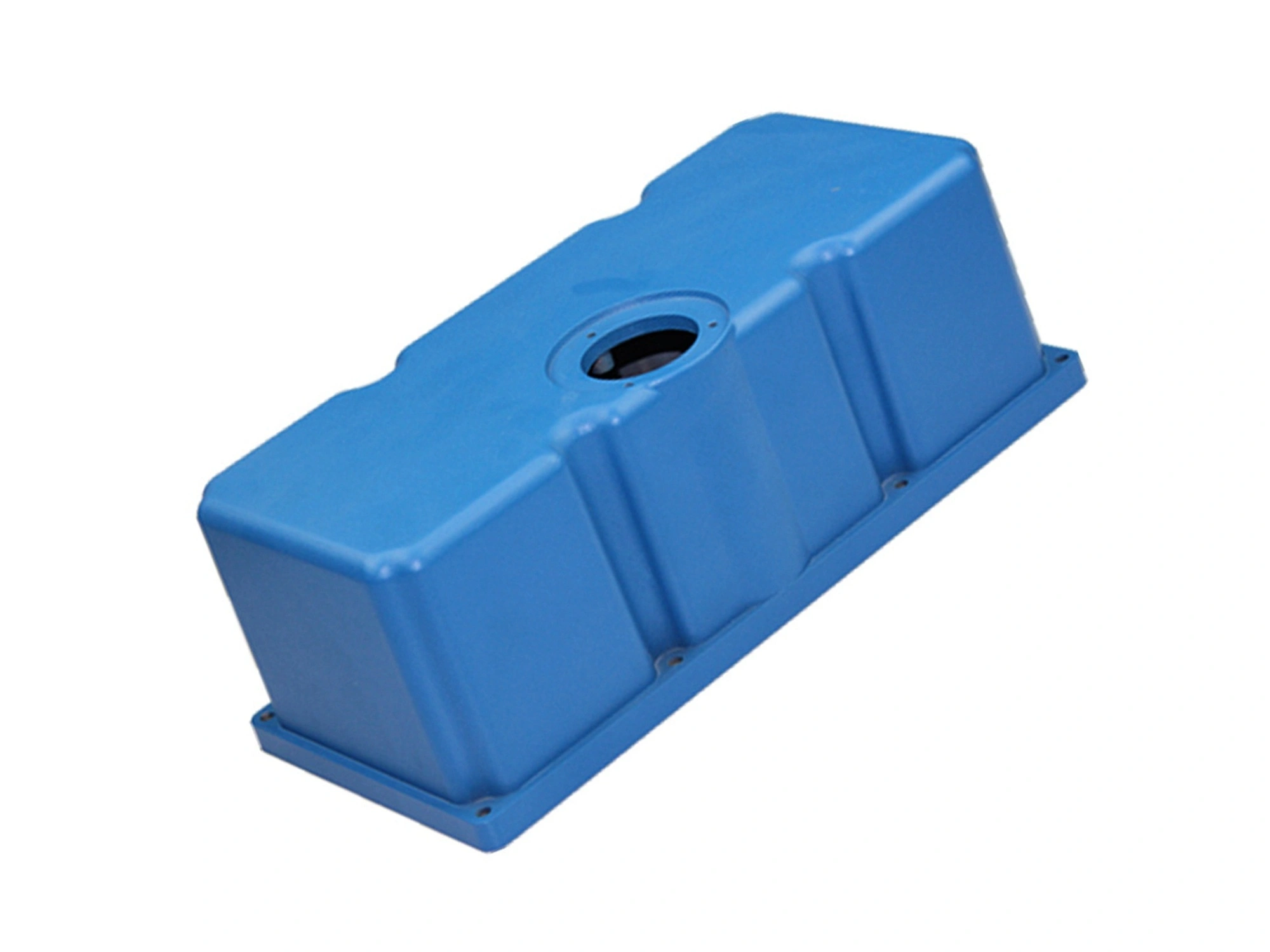

Our Post Process for Die casting includes CNC machining, sandblasting, tumbling, assembly, painting, powder coating, and arc anodizing. These processes enhance the part’s functionality, surface finish, durability, and aesthetic appeal, ensuring high-quality and precise finished products.

Die Casting Materials Available At Neway

At Neway, we offer a wide range of die casting materials, including high-performance aluminum, zinc, and copper alloys. We also provide specialized tool materials for mold making, ensuring optimal durability, precision, and quality for your casting needs.

Our Partners

Our partners include industry leaders like Volkswagen, Huawei, Nvidia, and Apple, showcasing our expertise in precision die casting for automotive, electronics, and accessories. We provide tailored solutions such as aluminum and Zamak die casting, CNC machining, and post-process services, ensuring high-quality, durable products for diverse sectors including automotive, technology, and consumer goods.

Learn More

Volkswagen: Automotive Parts Casting

Learn More

Huawei: Data Base Shell Casting

Learn More

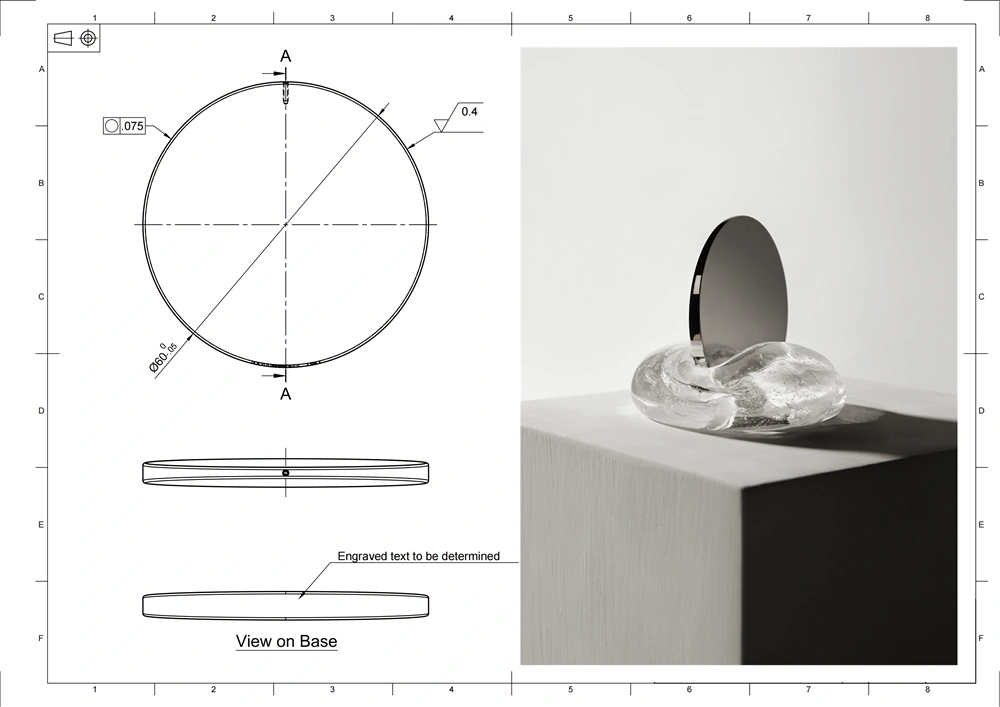

Adamonyte-Keidune: Zamak Parts Casting

Learn More

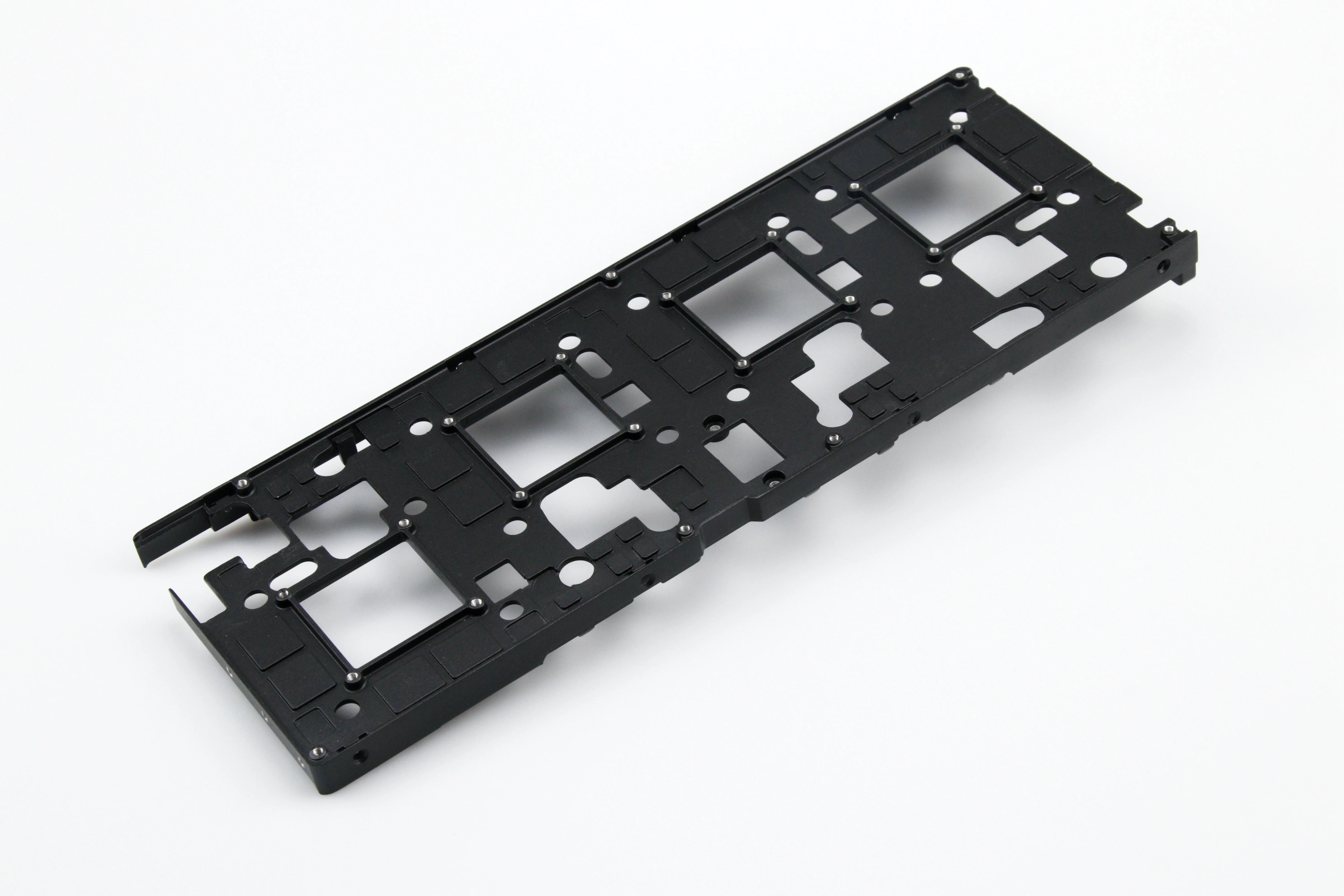

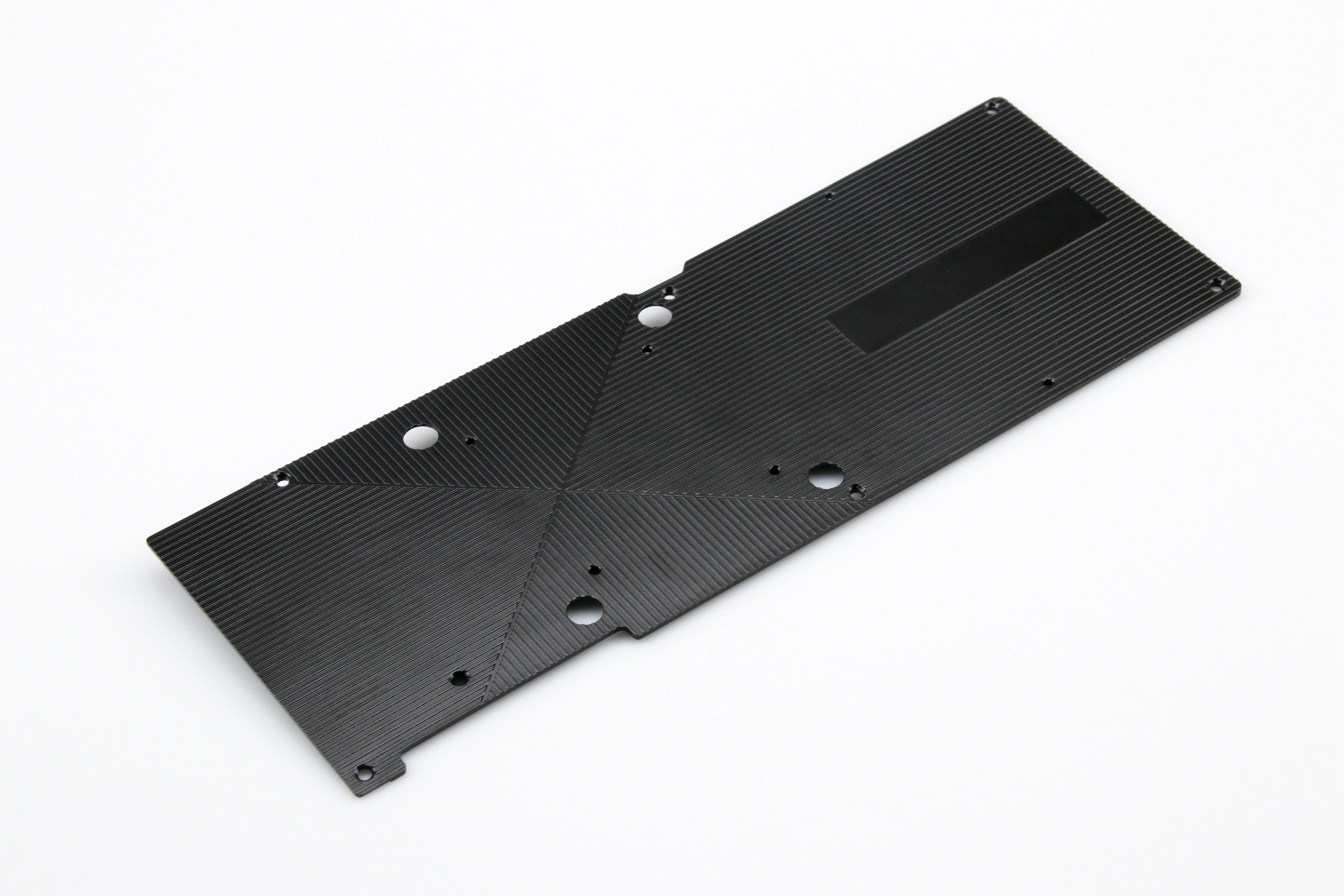

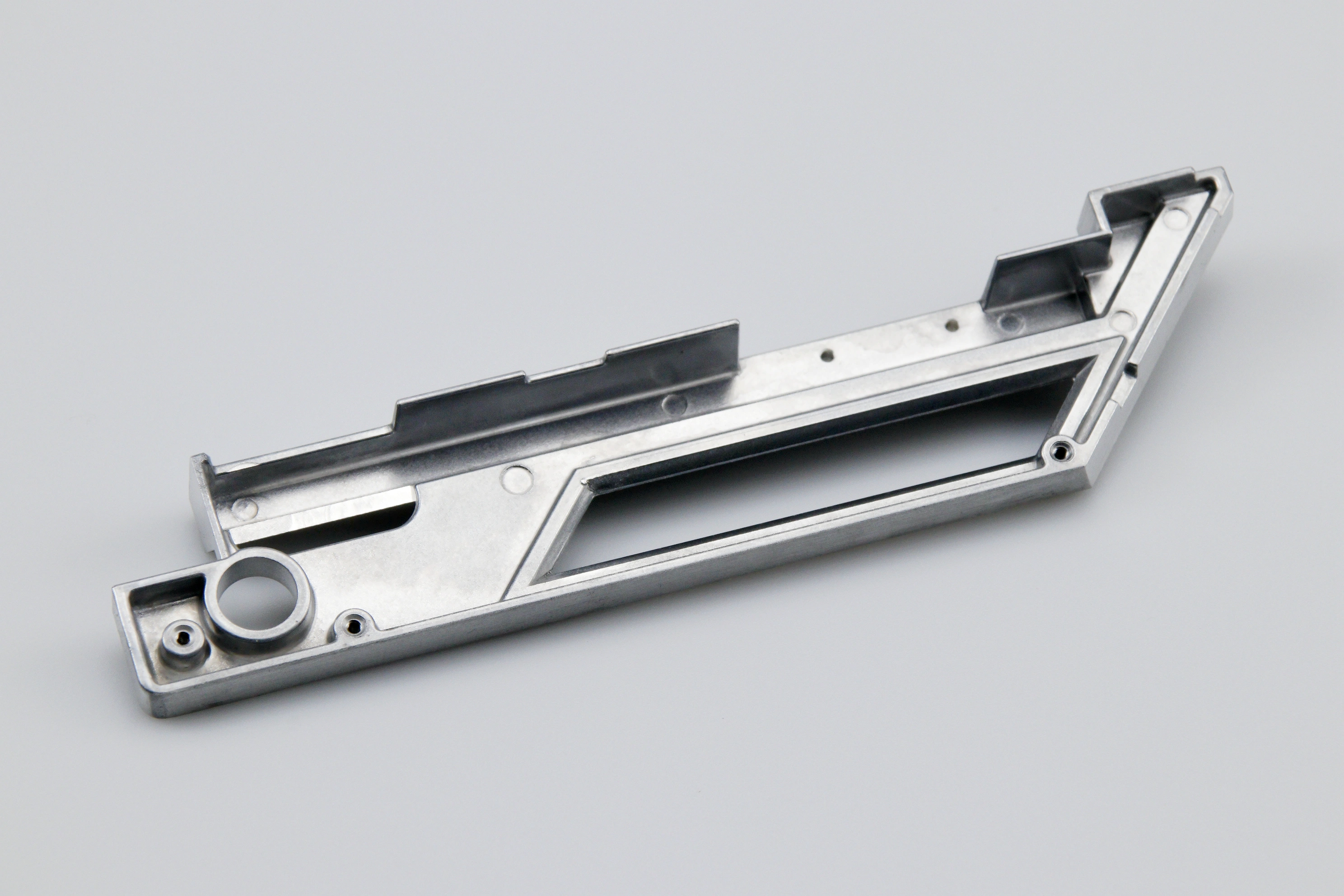

Nvidia: GPU Frame Die Casting

Learn More

Aorus: Computer Accessories Casting

Learn More

Apple: Earphone Hinge Casting and Machining

Learn More

Gigabyte: GPU Frame Die Casting

Learn More

Bosch: Power Tools Metal Casting

Learn More

Philips: Shaver Shell Zamak Die Casting

Learn More

BYD: Automotive Parts Casting

Learn More

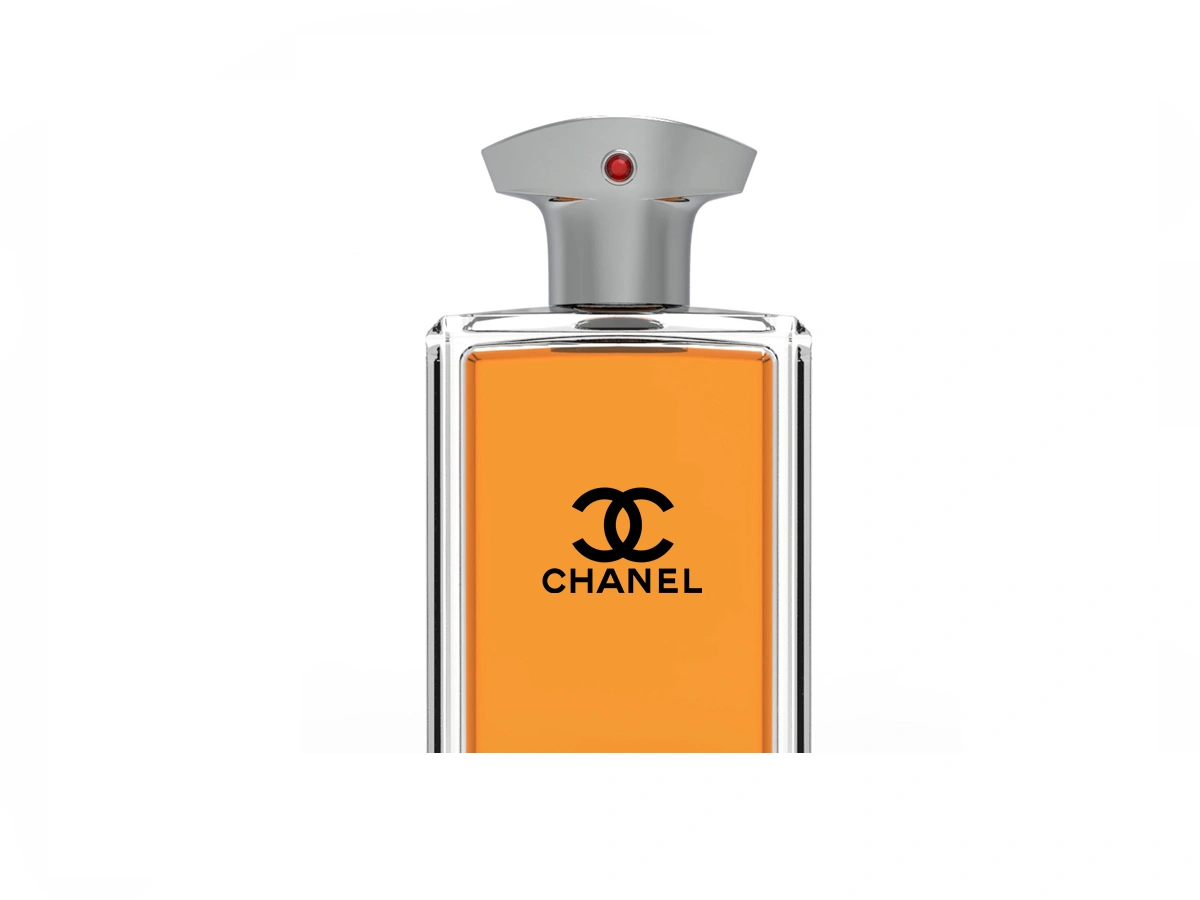

Chanel: Perfume Bottle Cap Casting

Learn More

Dirak: Lock System Accessories Casting

Custom Metal Casting Case Study

Our custom metal casting services have successfully delivered high-quality solutions across diverse industries. From Volkswagen’s precision ADC12 aluminum parts to Huawei’s aluminum data base shells, we specialize in high-pressure die casting for automotive, electronics, and luxury products. Our expertise includes casting, CNC machining, and coatings, ensuring durable, performance-driven components for brands like Apple, Bosch, and Chanel.

Let's Start A New Project Today

Metal Casting Parts Design Suggestions

Effective metal casting part design ensures optimal performance, reduced defects, and cost efficiency. Key suggestions include uniform wall thickness (1.5-4 mm), proper draft angles (2-3°), rounded fillets, realistic tolerances, and strategic gate placement. Consider rib thickness (max 60% of wall thickness), ejection pin location, and adequate venting. These design elements help enhance mold flow, part strength, and overall quality.

Explore Related Blogs

Explore Related Resources

Copyright © 2026 Diecast Precision Works Ltd.All Rights Reserved.