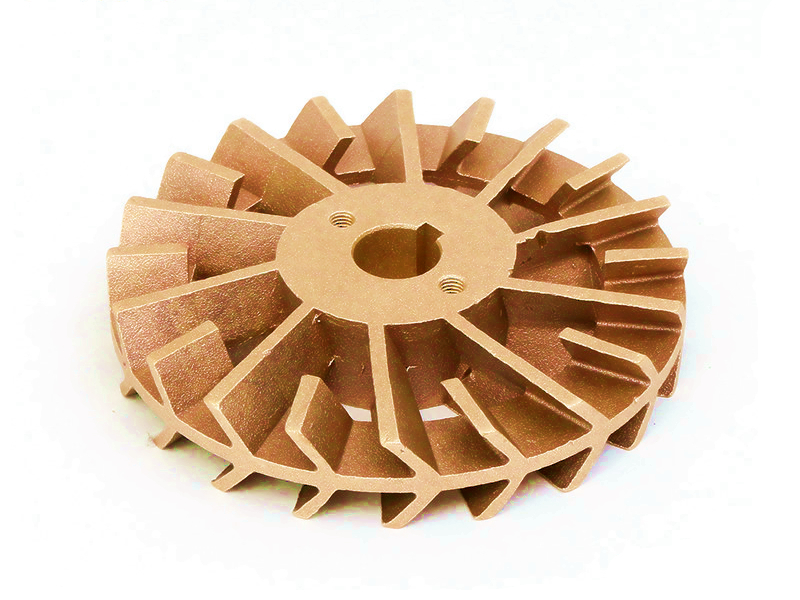

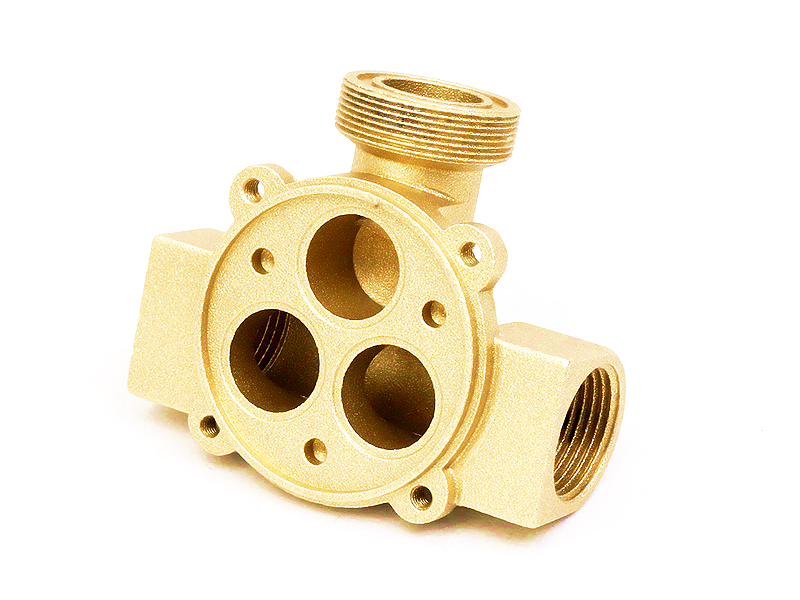

Reliable Copper Die Cast Pump System Impeller Accessories

In high-performance pump systems, impellers are critical components responsible for fluid movement, pressure generation, and hydraulic efficiency. Whether in HVAC circulation pumps, chemical handling systems, or industrial wash stations, impellers and their associated accessories must maintain dimensional stability, mechanical strength, and corrosion resistance over prolonged operating cycles. Copper alloy die casting provides a durable and scalable solution for manufacturing impellers and accessory parts that deliver consistent performance under demanding flow conditions.

At Neway, we specialize in copper die casting of impellers and pump accessories for OEMs and system integrators in water treatment, industrial processing, and HVAC sectors. We deliver impeller components with advanced tooling, high-conductivity copper alloys, and in-house finishing that meet stringent hydraulic, mechanical, and corrosion-resistance specifications.

Why Copper Alloys Are Ideal for Impellers

Copper and its alloys are widely used in pump systems due to their excellent thermal conductivity, resistance to erosion and biofouling, and good machinability. In high-speed rotating impellers, copper alloys dampen vibration, maintain material strength under thermal cycling, and offer superior protection against waterborne corrosives or chemical contaminants.

Key Advantages

Tensile strength: 210–400 MPa depending on the alloy

Corrosion resistance: suitable for chlorinated water, saline media, glycol, and mild acids

Density: 8.3–8.9 g/cm³ provides high mechanical damping and rotational stability

Dimensional tolerance: ±0.02 mm for keyway bores and hub centers

Wall thickness: as low as 1.5 mm for vanes or curved flow paths

Impeller speed compatibility: up to 3,000 RPM under balanced conditions

Copper impellers are particularly effective in reducing pump noise, extending bearing life, and withstanding cavitation effects in long-cycle industrial applications.

Applications of Copper Die Cast Impeller Components

Copper die cast impellers and accessories are used in fluid systems requiring high reliability, thermal control, and resistance to fluid-induced wear.

Component Type | Application Examples | Key Functional Requirements |

|---|---|---|

Pump Impellers | Centrifugal pumps, booster pumps, HVAC systems | Vane precision, rotational balance, cavitation resistance |

Impeller Hubs | Coupling with shafts or keyways | Tight fit, torque transmission, low runout |

Diffuser Plates | Inline flow regulation, multistage pump stages | Hydraulic stability, dimensional consistency, flow alignment |

Wear Rings | Axial spacing and clearance management | Surface hardness, corrosion resistance, low friction interface |

Back Vanes / Balance Disks | Pressure equalization for axial thrust control | Flatness, concentricity, erosion resistance |

Copper Alloys Used in Die Cast Impeller Manufacturing

Neway works with a range of copper-based alloys that offer an optimal balance between corrosion resistance, mechanical strength, and castability. All materials meet ISO 1634-1, ASTM B584, and EN 1982 standards for pump components.

Alloy | Thermal Conductivity (W/m·K) | Tensile Strength (MPa) | Best Use Cases |

|---|---|---|---|

C18200 | ~320 | ~340 | General pump impellers, diffuser plates, impeller hubs |

C17500 | ~180 | ~600 (age-hardened) | High-stress rotating components, compact systems |

CuZn10 | ~120 | ~340 | Lightweight, corrosion-resistant vanes and wear rings |

CuNi10Fe1 | ~40 | ~400 | Saltwater, HVAC chilled water systems, anti-biofouling parts |

C18200, a chromium copper alloy, is commonly used for its good machinability, pressure resistance, and excellent thermal stability in both clean and treated water systems.

Precision and Tolerancing in Impeller Casting

Pump impellers must maintain tight tolerances and balanced geometry to achieve consistent flow rates and pressure heads. Neway ensures dimensional stability across all production batches through controlled casting and post-processing.

Concentricity between bore and vane OD: ≤ 0.03 mm

Impeller bore tolerance: ±0.02 mm for shaft engagement

Wall thickness uniformity: ±0.10 mm for consistent hydraulic performance

Surface roughness: Ra ≤ 1.6 µm after tumbling or polishing

Porosity control: <0.5% verified via pressure testing or X-ray inspection

We offer CNC machining of shaft bores, threads, and balancing holes where necessary to achieve precise fit and operating performance.

Surface Treatments and Corrosion Resistance

Pump systems often operate in aggressive environments including chlorinated water, coastal installations, or chemically treated process fluids. Neway provides surface finishing options to increase longevity and enhance corrosion protection:

Electroplating: tin or nickel for high-purity water systems or chemical compatibility

Powder coating: corrosion-resistant layers for external or mounting surfaces

Painting: color-coded components for identification or maintenance schedules

Assembly: integration of inserts, shaft sleeves, seals, or impeller locks

All coatings meet RoHS/REACH standards and can be tested according to ASTM B117 or ISO 9227 for accelerated corrosion resistance performance.

Tooling and Production for Impeller Accessories

Neway’s in-house tool and die making ensures tight control over part geometry, vane contour accuracy, and casting repeatability.

Die material: H13 tool steel with hardened inserts for curved profiles

Tool life: 100,000–300,000 shots for copper alloy impellers

Casting size range: 30 mm to 300 mm diameter

Shot cycle time: 30–50 seconds depending on complexity

Rapid prototyping: available for early-stage hydraulic testing or tolerance checks

We also support low-volume legacy impeller components and mass production programs for OEM pump manufacturers.

Case Study: Copper Impeller for Industrial HVAC Booster Pump

An HVAC equipment manufacturer needed a copper alloy impeller for its new line of industrial-grade booster pumps. Requirements included:

Flow rate: 7 m³/h at 2.8 bar

Impeller diameter: 120 mm, 6-vane radial design

Shaft tolerance: ±0.02 mm with 8 mm keyed bore

Surface finish: Ra ≤ 1.2 µm

Operating environment: 70°C glycol-water mix

Volume: 120,000 units annually

Neway selected C18200 for its machinability and heat transfer performance. A dual-cavity slide-core mold was developed to support the curved vane geometry. After casting, parts were CNC machined, balanced, and nickel-plated. Final assemblies exceeded hydraulic efficiency and burst resistance targets in qualification tests.

Why Pump OEMs Choose Neway

Neway delivers complete impeller manufacturing services with proven reliability and technical support:

Full in-house control from die casting to machining and assembly

ISO 9001:2015-certified process control and batch traceability

Experience with clean water, wastewater, HVAC, and process fluid systems

Integrated prototyping, tooling, production, and logistics

Custom alloy and coating recommendations based on application conditions

Whether your pump system needs high-efficiency impellers, precision hubs, or corrosion-resistant balance components, Neway ensures consistent, high-quality performance in every part.

Conclusion

Copper alloy die casting provides the performance, durability, and efficiency required for impellers and pump accessories operating in demanding fluid systems. With excellent machinability, corrosion resistance, and casting precision, copper impeller components contribute to longer pump life, smoother flow, and more reliable system operation. At Neway, we deliver engineered copper solutions that meet the needs of global pump manufacturers.

To get started on your next impeller casting project, contact Neway for technical consultation and a custom quote.

Frequently Asked Questions

Which copper alloy offers the best corrosion resistance and strength for impellers?

How are vane geometries optimized for different pump designs?

What finishing options are available for copper impellers exposed to chlorinated or saline water?

What is the typical production lead time for die-cast pump impellers?

Can Neway support prototype impellers for hydraulic performance testing?