PVD Coating: The Ultimate Surface Treatment for Die Casting Tools and Dies

Introduction

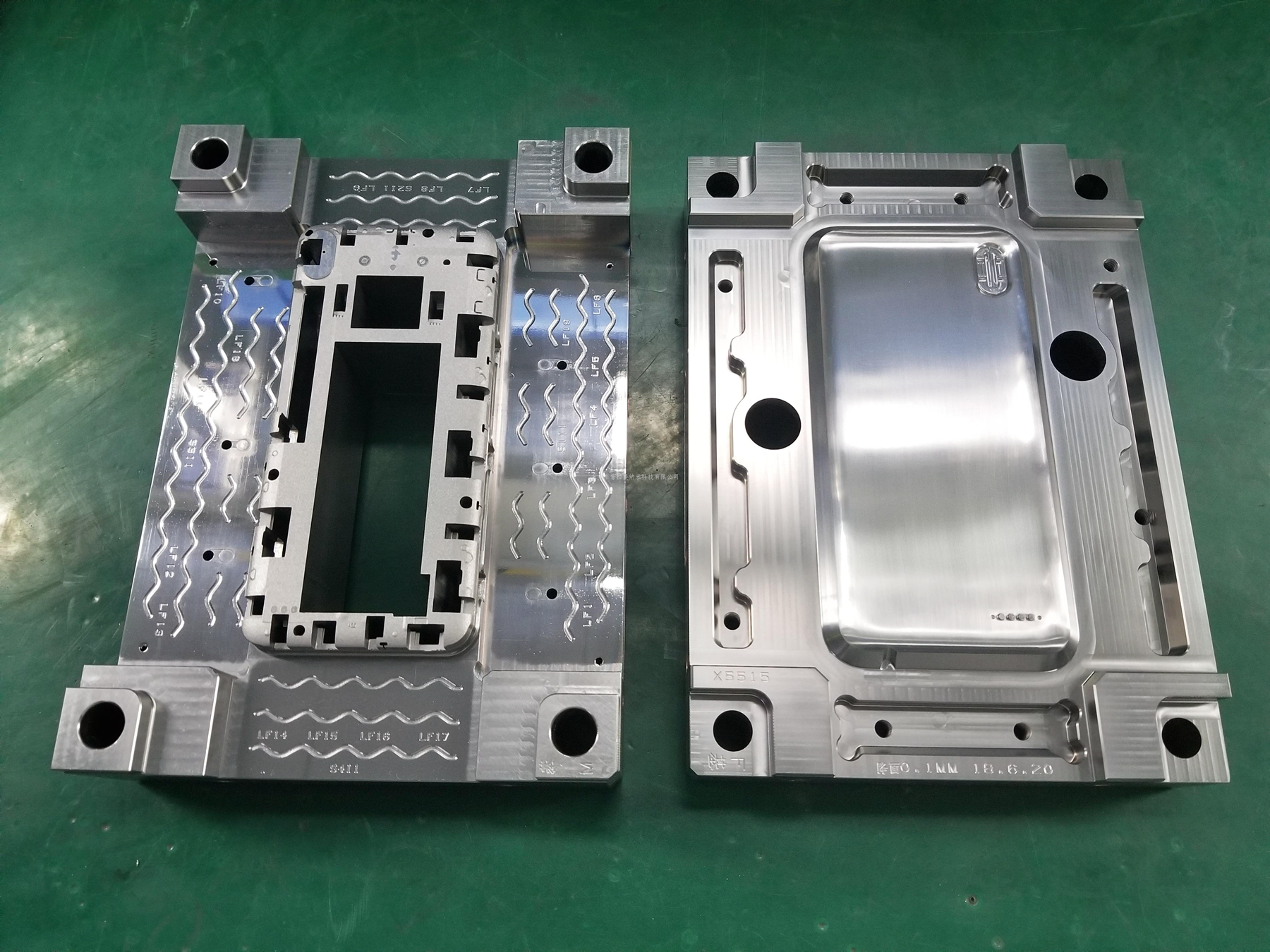

Die casting tools and dies are exposed to extreme thermal, mechanical, and chemical loads during operation, often exceeding 700°C in aluminum die casting or suffering rapid erosion in zinc and copper alloy production. Physical Vapor Deposition (PVD) coatings have emerged as one of the most effective surface treatments for die molds and core components to combat these challenges. Through a vacuum-based vaporization process, hard ceramic coatings like Titanium Nitride (TiN), Chromium Nitride (CrN), or Aluminum Titanium Nitride (AlTiN) are deposited on tool surfaces, creating a dense, wear-resistant layer that significantly prolongs tool service life. This blog explores the mechanism, benefits, and real-world applications of PVD coatings for die casting tooling used by Neway.

What Is PVD Coating?

Physical Vapor Deposition is a low-temperature, vacuum-based coating technique where metallic and reactive gases are ionized and deposited as thin films on metallic surfaces. The typical process involves:

Operating temperatures between 150°C and 500°C

Vacuum pressures around 10⁻³ to 10⁻⁵ torr

Coating thickness ranging from 1 to 5 microns

Deposition rates of 0.1–0.5 µm/hr

The result is a highly uniform, adherent layer that modifies only the surface without altering core tool properties—a crucial factor for maintaining tight dimensional tolerances in complex die casting geometries.

Key Benefits of PVD Coatings in Die Casting

Benefit | Typical Improvement | Industry Impact |

|---|---|---|

Wear Resistance | Hardness of 2000–3000 HV | Reduces abrasion and erosion in gating and cavity areas |

Thermal Stability | Stable up to 800–1100°C (depending on coating) | Resists softening during high-pressure aluminum or copper die casting |

Lubricity | Reduced friction coefficient (0.2–0.4) | Enhances part ejection, reduces galling and soldering |

Corrosion Resistance | Chemically inert coatings | Prevents oxidation and chemical attack from molten metals |

PVD-coated tools retain their performance characteristics significantly longer than uncoated counterparts, especially when used with aggressive alloys like A380 aluminum, Zamak 5 zinc, or Brass 360.

Common PVD Coating Materials for Casting Tools

The choice of coating depends on the casting material, temperature range, and tool geometry. Popular PVD coatings include:

Titanium Nitride (TiN): Offers a balance of hardness (HV ~2200), wear resistance, and thermal stability up to 600°C. Ideal for zinc die casting tools.

Chromium Nitride (CrN): Provides superior oxidation resistance and ductility. Effective for aluminum casting where anti-soldering is essential.

Aluminum Titanium Nitride (AlTiN): Withstands up to 900–1100°C, suitable for high-pressure die casting of aluminum and copper-based alloys.

Titanium Carbonitride (TiCN): Enhances abrasion resistance with higher hardness but slightly reduced thermal performance.

These coatings are typically applied to tool steels such as H13, D2, and Tool Steel S7 to achieve the best synergy between substrate toughness and surface hardness.

Practical Application in Die Casting Operations

In real-world production environments, PVD-coated dies are used for:

Shot Sleeves and Plungers: Reducing wear and improving aluminum flow consistency.

Core Pins and Ejectors: Minimizing galling and improving part release in zinc alloy casting.

Cavity Inserts: Extending cycle life and reducing downtime due to soldering or erosion.

A study conducted across 10,000 aluminum die casting cycles using PVD-coated H13 core pins showed a 60–70% reduction in maintenance frequency and a 20% improvement in dimensional consistency compared to untreated pins.

Integration with Tool Maintenance and Post-Processing

PVD coating is most effective when used with proper tool preparation and maintenance. Pre-treatment steps such as polishing (Ra < 0.4 µm) and degassing are crucial for coating adhesion. Post-use, tools may require re-polishing but rarely need recoating for the first 30,000–50,000 cycles, depending on casting alloy and process parameters.

Neway’s post-processing and tool maintenance services ensure PVD coatings deliver optimal long-term results, extending tool lifespan and maintaining part quality standards in mass production environments.

FAQs

Which PVD coating is best for aluminum die casting dies?

How does PVD compare to nitriding in tool performance?

What surface preparation is required before PVD coating?

Can PVD coatings be reapplied to worn tools?

What is the typical ROI for PVD-coated die tools in high-volume production?