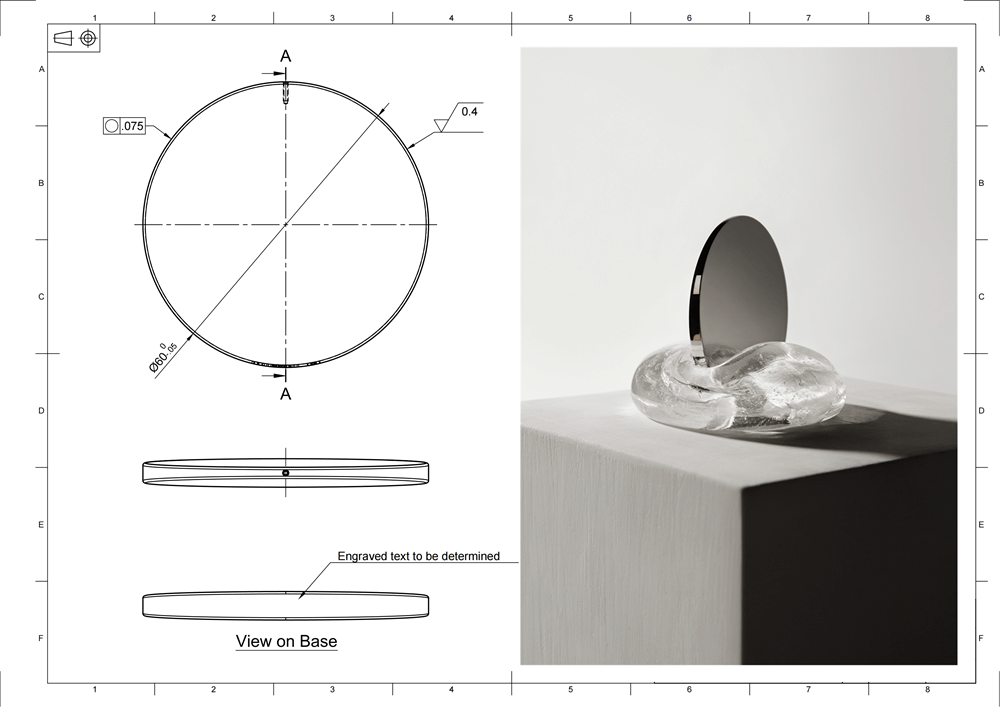

Adamonyte-Keidune Zamak Parts Casting and PVD Coating Mirror Manufacturing

Zamak die casting has become a staple in the decorative metal manufacturing industry, enabling the efficient production of high-detail, dimensionally stable parts. It provides the ideal balance of strength, fluidity, and finish quality for high-end mirror assemblies.

This project focuses on the collaborative manufacturing of zamak alloy components with a mirror-like appearance, achieved through precision casting and advanced PVD surface treatment. The result is a line of ornamental parts that meet aesthetic and functional demands in premium consumer products.

Zamak Die Casting for Decorative and Functional Parts

Zamak 3 and Zamak 5 were selected due to their excellent fluidity and high-fidelity surface detail, ideal for mirror frame embellishments and support structures. These alloys are widely used in zinc die casting for ornamental and cosmetic components requiring superior finish quality.

Material and process data:

Tensile strength: 280–310 MPa

Wall thickness: 1.2–2.5 mm

Casting tolerance: ±0.05 mm (ISO 8062 CT6)

Brinell hardness: ~85 HB

Surface porosity: <0.3% (verified via X-ray inspection)

The Zamak die casting process ensured fine contour replication, reduced internal defects, and dimensional repeatability for decorative assemblies.

Mold Engineering and Surface Optimization

The mold featured mirror-grade cavity inserts with Ra ≤ 0.4 µm surface finish and multi-slide actions to accommodate undercuts and recessed geometry. H13 tool steel with vacuum heat treatment extended die life beyond 100,000 cycles.

Tooling specifications:

Mold material: H13 with nitrided surface

Draft angle: 1.5° typical for vertical faces

Multi-slide core actions: for internal recesses

Cooling system: embedded channels with sensor feedback

Discover more about tool and die making for small, highly detailed metal parts used in cosmetic or consumer hardware.

Post-Processing and CNC Finishing

After casting, the parts underwent burr removal and tumbling to soften edges, followed by precision CNC post-machining to prepare mating features and mounting holes.

Key machining metrics:

Hole position accuracy: ±0.02 mm

Edge chamfering: 0.3 mm uniform

Final surface roughness: Ra ≤ 0.8 µm

This tight finishing ensured perfect integration with stainless or glass components in final mirror assemblies.

PVD Coating for Mirror-Like Finish and Durability

A multi-layer PVD (Physical Vapor Deposition) coating was applied to deliver a luxurious, high-reflectivity chrome appearance. The process produces highly durable metallic finishes used in high-end bathroom, furniture, and electronics hardware.

Coating process parameters:

Base layer: Titanium or CrN for adhesion

Reflective top layer: Chrome or gold

Coating thickness: 0.3–0.5 µm

Surface hardness: >3H

Corrosion resistance: >240 hours salt spray per ASTM B117

The uniformity and adhesion level were validated using ASTM D3359 cross-cut tape and pencil hardness tests.

Quality Control and Assembly Support

To meet strict aesthetic standards, all parts underwent multi-stage inspection, including:

100% visual check under 600 lux diffused lighting

Coating thickness measurement via eddy current probe

Dimensional sampling using CMM

Static-safe cleanroom packaging

Packaging used anti-scratch trays and poly layers to protect PVD surfaces from abrasion during shipping. This approach is part of our one-stop service model—streamlining production, finishing, inspection, and packaging in a unified workflow.

Flexible Short-Run Production for Premium Brands

This project was part of a limited-edition mirror product line with varying finishes and formats. Our low-volume manufacturing approach supported batch sizes as small as 2,000 units per variant, ensuring design exclusivity and cost control.

Each new variant used standard tooling with interchangeable inserts, reducing tooling cost by 30% and tooling changeover time to under 24 hours.

FAQs

Why is zamak preferred for decorative die casting over other zinc alloys?

What are the coating durability standards for high-gloss decorative hardware?

How are dimensional tolerances managed for multi-part cosmetic assemblies?

What post-processing methods are essential before PVD coating?

How does low-volume production affect tooling and design flexibility?