Bosch Power Tools Custom Hardware and Accessories Metal Casting and Assembling

Power tool components demand strength, precision, and durability to endure heavy-duty use and harsh environments. High-pressure die casting combined with post-machining and mechanical assembly offers a scalable, cost-effective solution.

This case study details the custom development of metal housings, structural supports, and functional accessories for professional electric tools. It focuses on material selection, process engineering, and assembly strategies that ensure quality and repeatability at production scale.

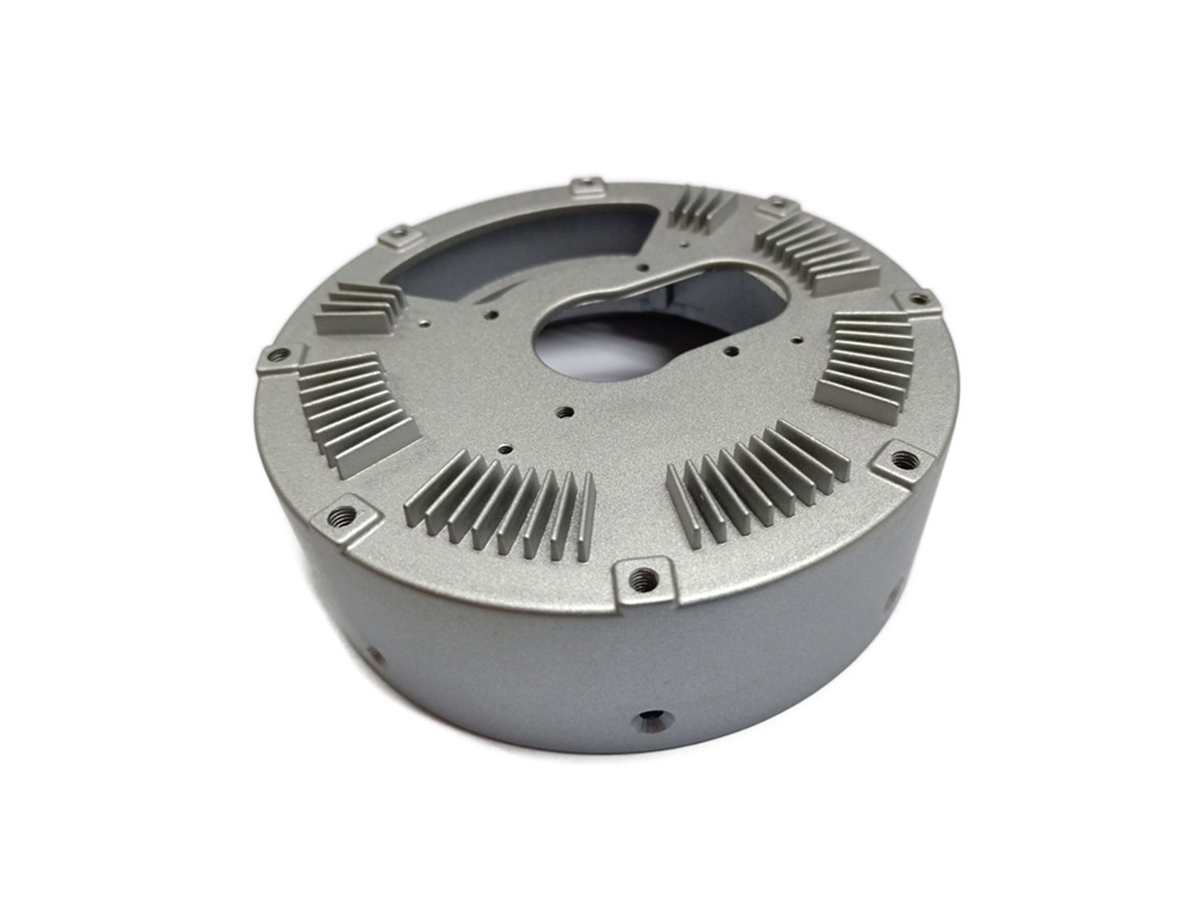

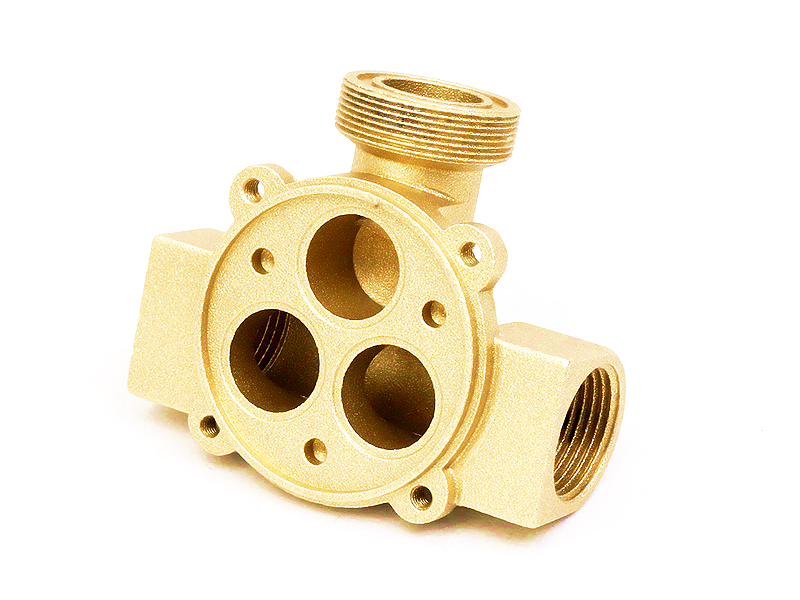

Die Casting for Structural Tool Components

Key mechanical parts such as gearboxes, end casings, and handle reinforcements were manufactured using high-pressure die casting (HPDC). Materials included Zamak 5 for internal locking features and A380 aluminum alloy for outer structural housings due to their respective mechanical and thermal properties.

Material Comparison: A380 vs. Zamak 5

Property | A380 Aluminum Alloy | Zamak 5 Zinc Alloy |

|---|---|---|

Ultimate Tensile Strength (MPa) | 310 | 295 |

Yield Strength (MPa) | 165 | 250 |

Elongation at Break (%) | ~3.5 | ~7.5 |

Thermal Conductivity (W/m·K) | 96 | 109 |

Density (g/cm³) | 2.74 | 6.6 |

Castability (thin-wall features) | Excellent | Very Good |

Typical Use | Housings, brackets | Internal mechanisms |

Both alloys were cast within ISO 8062 CT6 tolerances and verified for internal soundness with X-ray inspection (ASTM E505), ensuring porosity remained below 0.5%.

Tooling for Multi-Part Functional Assemblies

For complex part geometries, we developed multi-cavity tooling with collapsible cores and lifters, designed for high-volume, tight-tolerance applications. The molds were built using H13 steel, hardened and nitrided to resist thermal fatigue and wear.

Tooling highlights:

Core design: optimized for undercuts and recesses

Mold steel: H13, HRc 46–50, vacuum heat-treated

Die life: >100,000 cycles

Surface finish: Ra ≤ 0.8 µm on cavity walls

Balanced gating and conformal cooling per die design best practices

Post-Machining and Dimensional Tuning

After casting, parts were CNC-machined to meet the power tool assemblies' fitment and tolerance requirements. Functional areas such as gear shafts, bearing seats, and mounting faces were processed using 5-axis machining centers.

Machining standards (ISO 2768-f):

Thread tapping: M4–M8 (ISO 965-1, class 6H)

Flatness: ≤0.05 mm

Concentricity: ≤0.02 mm

Surface finish: Ra ≤ 1.6 µm at sealing faces

Discover our precision CNC post-machining services tailored for dimensionally critical hardware components.

Surface Finishing for Performance and Brand Appearance

The cast and machined parts underwent tailored surface treatments to improve appearance, corrosion resistance, and tactile performance. These finishes were selected based on material, environment, and ergonomic contact.

Finishing processes included:

Powder coating: 60–80 µm thickness, 1,000+ hours salt spray resistance (ASTM B117)

Anodizing: applied to aluminum parts for dielectric insulation and wear resistance

Tumbling and vibratory polishing: used on Zamak for soft-edge transitions and improved grip aesthetics

Visual surfaces were laser marked with part numbers and branding after finishing.

Mechanical Assembly Integration

Following machining and finishing, components were pre-assembled to form complete tool housings or subassemblies. Assembly operations included fastener installation, dowel pressing, gasket insertion, and mechanical testing.

Assembly process details:

Torque-controlled screw driving (±5%)

Alignment checks using vision-based inspection

Spring and slider pre-loading

Final subassembly packaged in protective ESD-safe trays for shipping

Our assembly services ensure readiness for final integration at the OEM’s production line.

Production Scale and Quality Management

Production was scaled to meet monthly output exceeding 100,000 components across 12 parts. All steps followed ISO 9001:2015 quality procedures with full batch traceability from material to packaging.

QA protocols implemented:

First Article Inspection (FAI) with full dimensional layout

Inline SPC on critical-to-function (CTF) features

Coating adhesion: ASTM D3359 (5B rating)

Visual inspections: ISO 1302 N6/N7 grade finishes

Non-destructive testing: random X-ray verification of die castings

FAQs

Which alloys offer the best durability for handheld electric tool housings?

What dimensional tolerances are achievable with die casting and machining integration?

How are surface finishes selected for both protection and branding?

What quality control measures are standard for structural cast tool parts?

How are components assembled and packaged to avoid damage during transport?