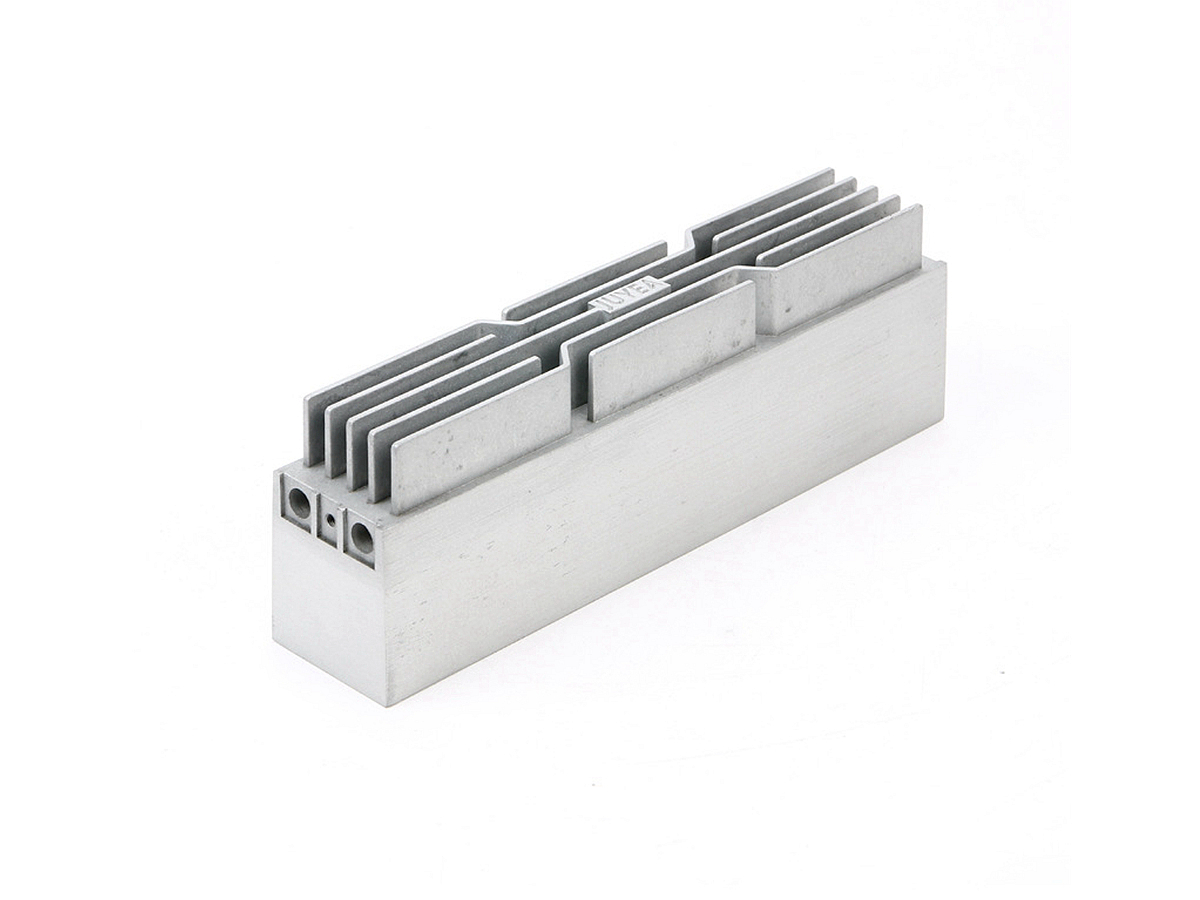

BYD Custom Automotive Parts Aluminum Die Casting Manufacturer

Electric vehicle platforms rely on lightweight structural components with strength and thermal performance. Aluminum die casting delivers this balance, supporting large-scale production while meeting tight dimensional and mechanical requirements.

This case study showcases the aluminum die casting processes used to manufacture custom structural and mounting parts for EV systems. Every step from tooling and casting to CNC finishing and QC validation meets strict automotive-grade standards.

Aluminum Die Casting for EV Structural Integration

Aluminum alloy components were used across motor mounts, inverter housings, and body structure elements to reduce vehicle weight and improve energy efficiency. A380 and A360 alloys were selected for their castability, strength, and thermal conductivity.

Material Performance Comparison

Property | A380 Alloy | A360 Alloy |

|---|---|---|

Ultimate Tensile Strength (MPa) | 310 | 317 |

Thermal Conductivity (W/m·K) | ~96 | ~120 |

Corrosion Resistance | Moderate | High |

Die Castability | Excellent | Very Good |

Elongation at Break (%) | ~3.5 | ~4.5 |

Typical Applications | Brackets, Housings | Inverter Casings |

For more on alloy selection for structural EV parts, visit our automotive aluminum casting services.

Tooling Design and Process Stability

Tooling was developed with multi-slide dies and advanced thermal control systems. Mold flow simulation (MAGMASOFT®) was applied to optimize gate and runner layout and to prevent flow imbalance or shrinkage cavities.

Tooling specifications:

Mold steel: H13, nitrided, shot life >120,000

Cavity finish: Ra ≤ 0.8 µm

Cooling: conformal channels, ±3°C control

Die size: up to 650 x 600 mm

Fill time: ≤0.20 seconds (via high-speed injection)

Our tool and die engineering supports consistent production of dimensionally demanding automotive parts.

High-Pressure Die Casting Process Control

Die casting was performed on 800–1250 ton cold chamber machines, equipped with servo-controlled plunger systems and vacuum-assisted venting for porosity minimization.

Casting process parameters:

Injection pressure: 85–125 MPa

Shot speed: 2.5–3.2 m/s

Mold temperature: 240–260°C

Shot repeatability: ±2%

Porosity level: Class 2 or better per ASTM E505

See our aluminum HPDC capabilities for high-integrity automotive-grade casting solutions.

CNC Machining for Dimensional Precision

Post-casting machining ensured geometric accuracy of critical features, including O-ring grooves, mounting planes, and threaded inserts. CNC work was completed using 4- and 5-axis vertical machining centers.

Machining tolerances:

Flatness: ≤0.05 mm on sealing faces

Bore tolerance: H7 class (±0.015 mm)

Threaded hole accuracy: ISO metric M6–M10

Surface roughness (Ra): ≤1.6 µm on contact zones

Review our post-machining services to see how final fitment is ensured for EV structural assemblies.

Surface Treatment for Environmental Resistance

Given automotive exposure to road salt, moisture, and vibration, treated surfaces were required. Depending on the location, anodizing or powder coating was used.

Anodizing: 12–20 µm film, corrosion resistance >500 hrs (ASTM B117)

Powder coating: 80 µm thickness, custom matte black or silver

Sealing surfaces left uncoated or masked for thermal compound application

All coatings passed ASTM D3359 adhesion (5B rating) and ISO 9227 corrosion tests.

Automotive-Grade Inspection and Traceability

Each part followed an IATF 16949 production flow, including full PPAP documentation, batch traceability, and process capability studies.

QC systems included:

First Article Inspection (FAI) with full GD&T layout

Inline SPC data on CTF features (CpK ≥1.67)

3D laser scanning vs. CAD model for every batch

X-ray on 100% of safety-critical parts

Serialization via laser marking + QR code tracking

Our automotive mass production solutions support prototype validation and full-scale rollout for new EV platforms.

FAQs

Which aluminum alloys are most suitable for high-load structural EV parts?

How is porosity controlled in high-pressure aluminum die casting?

What tolerance classes apply to post-machined automotive castings?

How are surface coatings tested for automotive corrosion resistance?

What traceability measures are used for die cast parts in automotive supply chains?