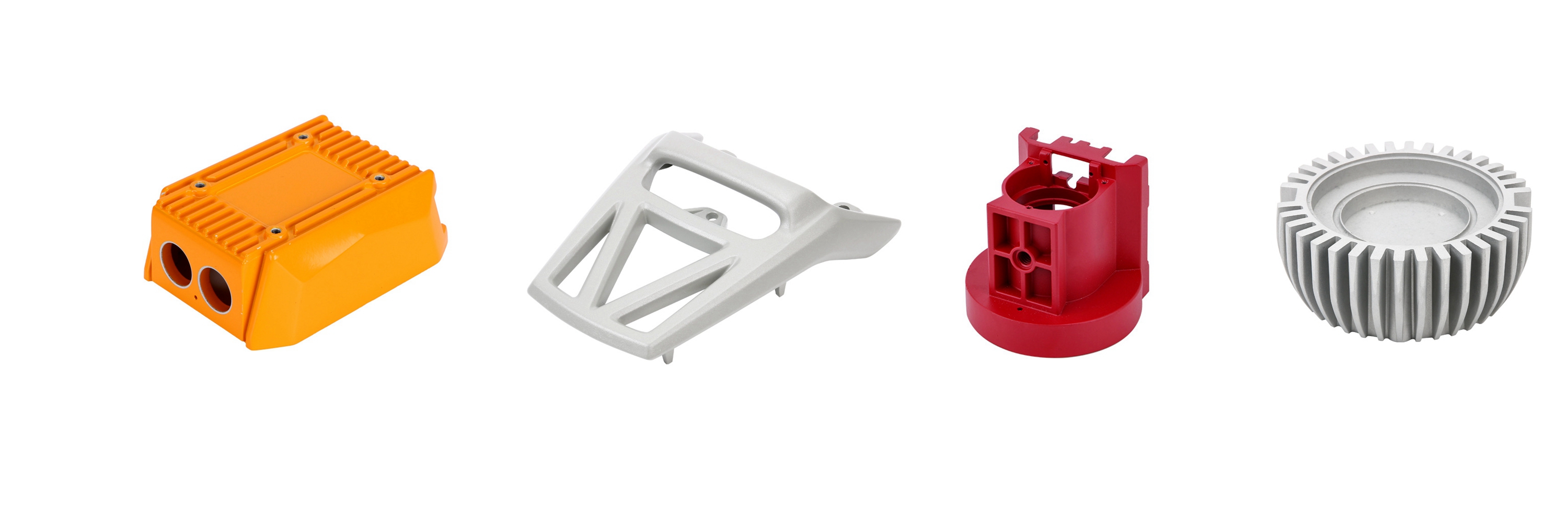

Anodizing Service For Die Castings

Anodizing Service for die castings is an electrochemical process that enhances metal surfaces by increasing corrosion resistance, surface hardness, and aesthetic appeal. It also improves adhesion for subsequent coatings, providing durable, long-lasting protection while offering a visually appealing finish.

- Corrosion resistance: Protects parts from environmental damage.

- Durability: Increases surface hardness and wear resistance.

- Aesthetic appeal: Enhances appearance with vibrant colors.

- Improved adhesion: Enhances paint or coating bonding.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

What Is Anodizing Service For Die Castings

Anodizing Service for die castings is an electrochemical process that enhances the surface of metal parts, increasing corrosion resistance, surface hardness, and aesthetic appeal. It also improves paint adhesion, providing durable protection and a visually appealing finish for die-cast components.

Properties of Anodizing

Anodizing enhances the properties of aluminum and titanium through an electrochemical process. It provides increased corrosion resistance, improved hardness, and better wear resistance. Anodized surfaces are also environmentally resistant and can be customized with various colors and textures. The process offers electrical insulation and is widely used in aerospace, automotive, and architectural applications due to its durability and aesthetic options.

Let's Start A New Project Today