Arc Anodizing Service For Die Castings

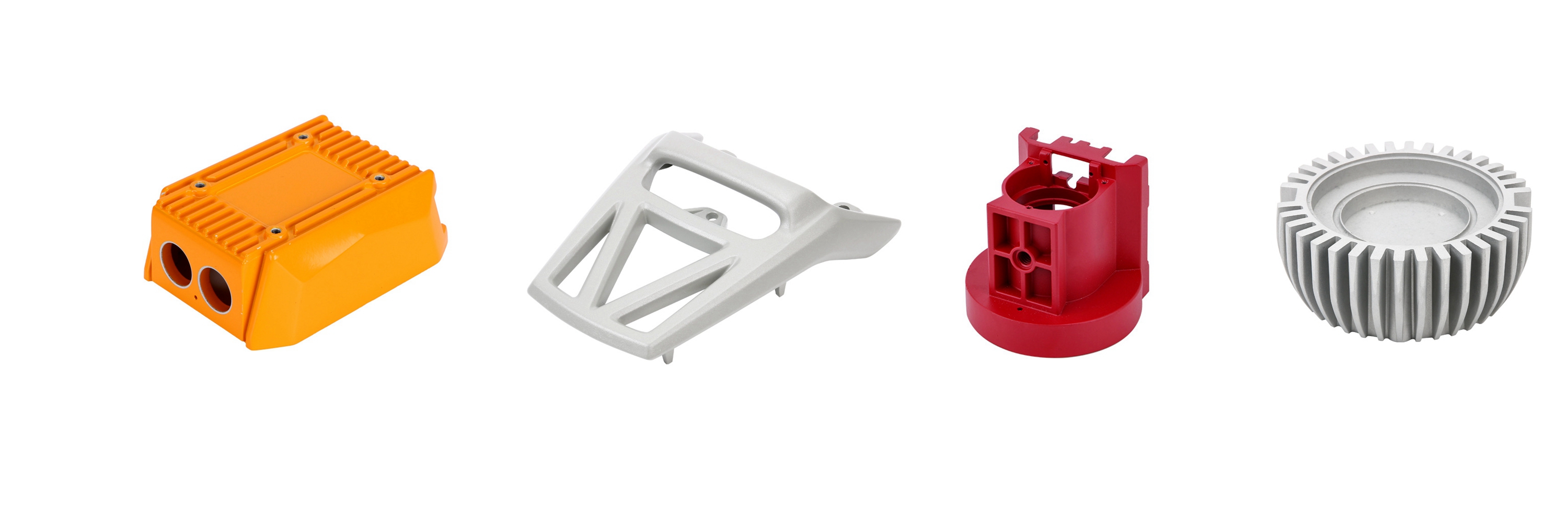

Arc Anodizing Service for die castings is an advanced electrochemical process that creates a durable, corrosion-resistant oxide layer on metal surfaces. This method enhances wear resistance, improves aesthetics with custom colors, and increases the overall longevity of die-cast components.

- Superior durability: Enhances surface hardness and strength.

- Corrosion protection: Provides robust resistance to rust.

- Aesthetic variety: Offers vibrant, custom color finishes.

- Increased wear resistance: Extends lifespan of die-cast parts.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

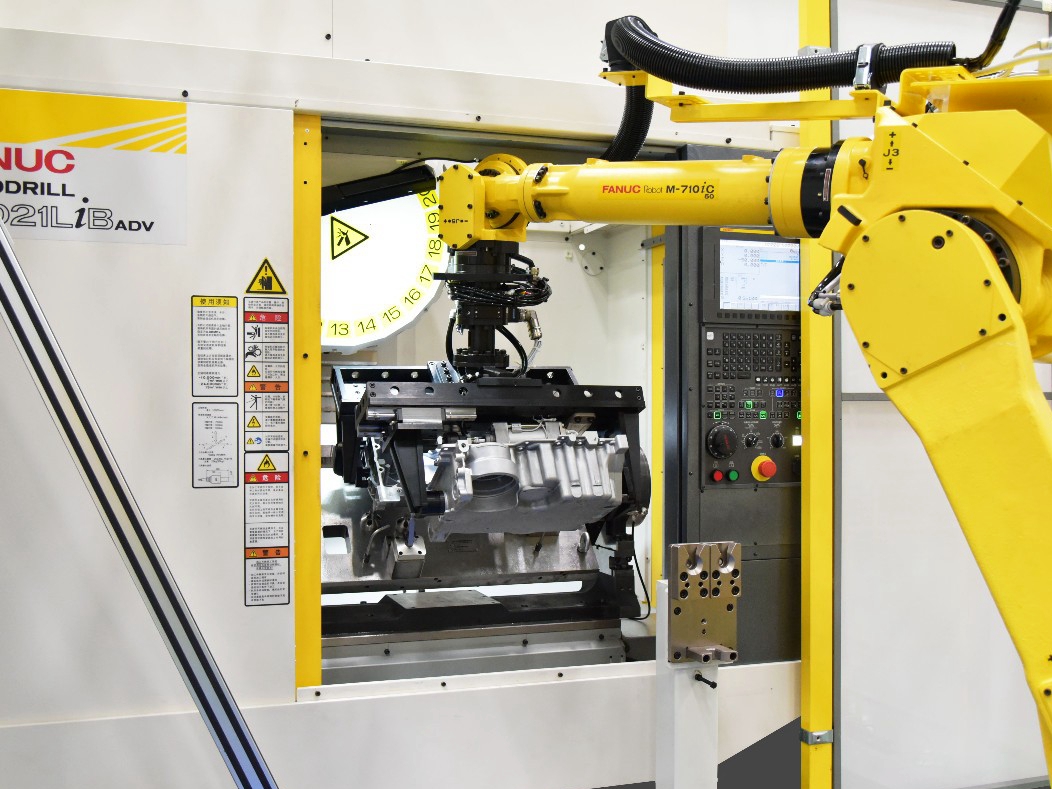

What Is Arc Anodizing Service For Die Castings

Arc Anodizing Service for die castings is a high-performance electrochemical process that creates a tough, corrosion-resistant oxide layer on metal surfaces. This method enhances durability, offers vibrant color options, and improves wear resistance, making it ideal for demanding applications.

Properties of Arc Anodizing

Arc anodizing enhances the surface of aluminum, titanium, and magnesium, providing excellent hardness, corrosion resistance, and wear resistance. It offers various color and texture options, including clear, black, and gold. The process delivers superior environmental resistance and electrical insulation, making it ideal for aerospace, automotive, and outdoor applications. It provides durable, high-performance finishes with moderate cost and processing time.

Let's Start A New Project Today