Assembling Service For Die Castings

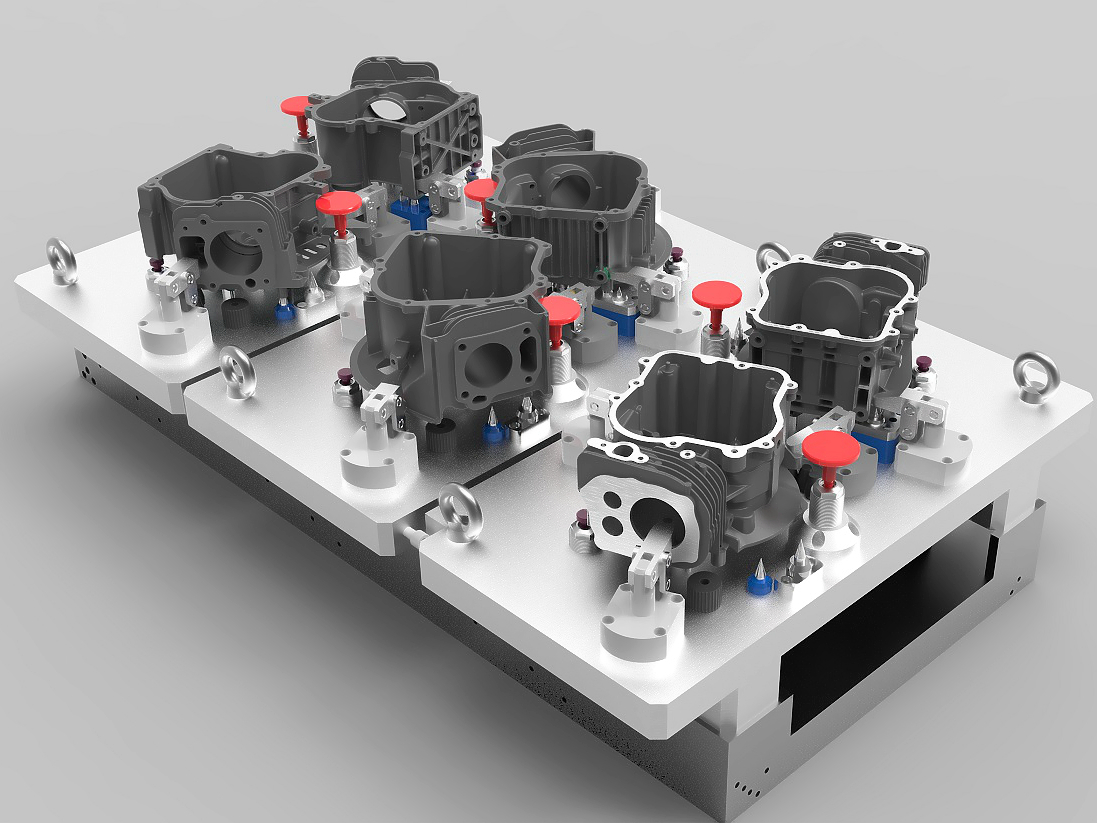

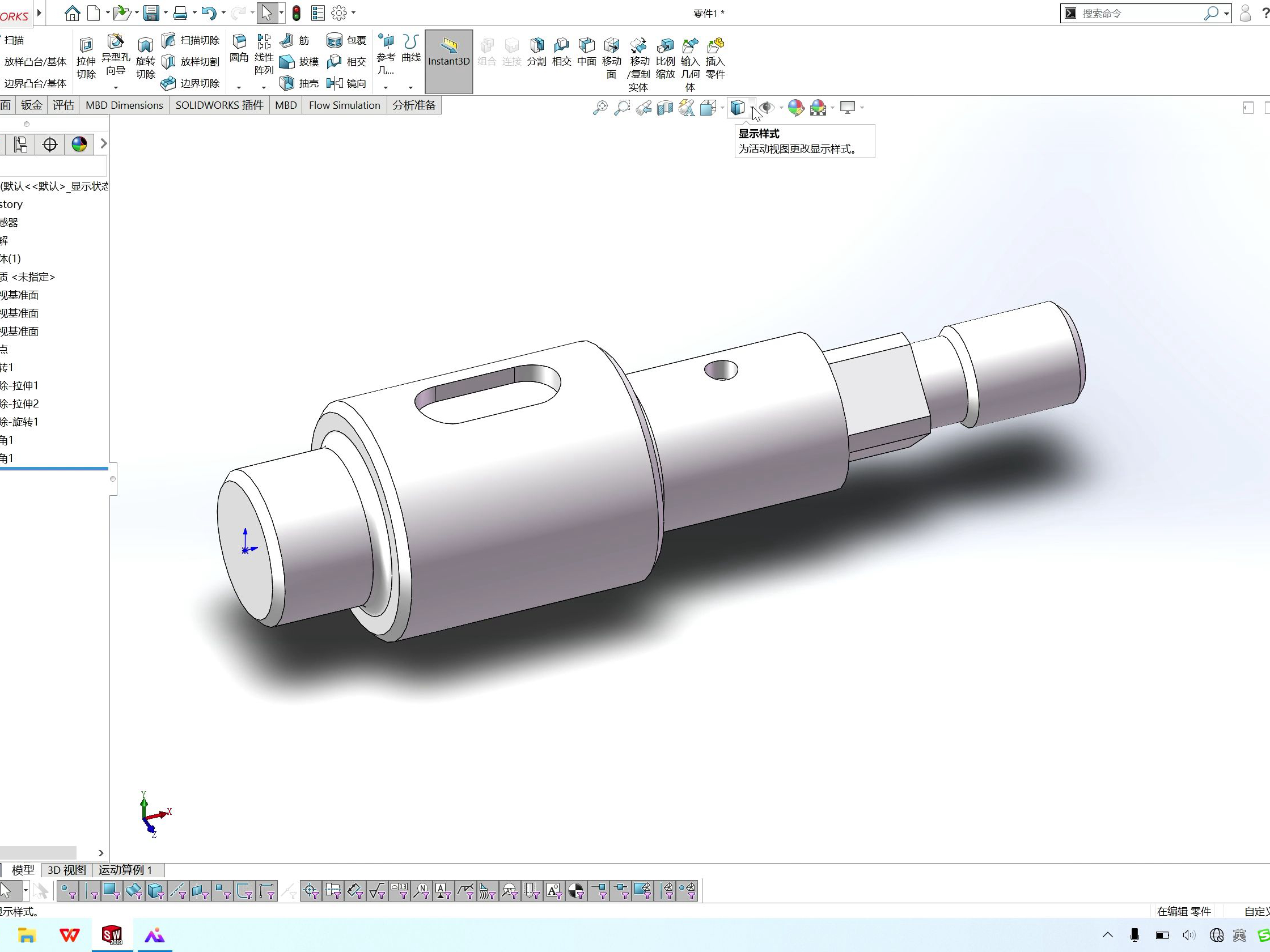

Assembling Service for die castings involves the integration of various components into a complete product. It includes processes like gluing, welding, hardware assembly, and final product assembly, ensuring precise alignment, functionality, and readiness for delivery or further processing.

- Gluing: Bonds components using adhesive materials.

- Welding: Joins parts through heat and pressure.

- Hardware Assembly: Attaches fasteners, nuts, bolts, etc.

- Finished Product Assembly: Combines all components into final product.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

What Is Assembling Service For Die Castings

Assembling Service for die castings involves combining individual components into a complete, functional product. This includes gluing, welding, hardware assembly, and final product assembly, ensuring all parts are securely joined, aligned, and ready for final inspection, packaging, or use.

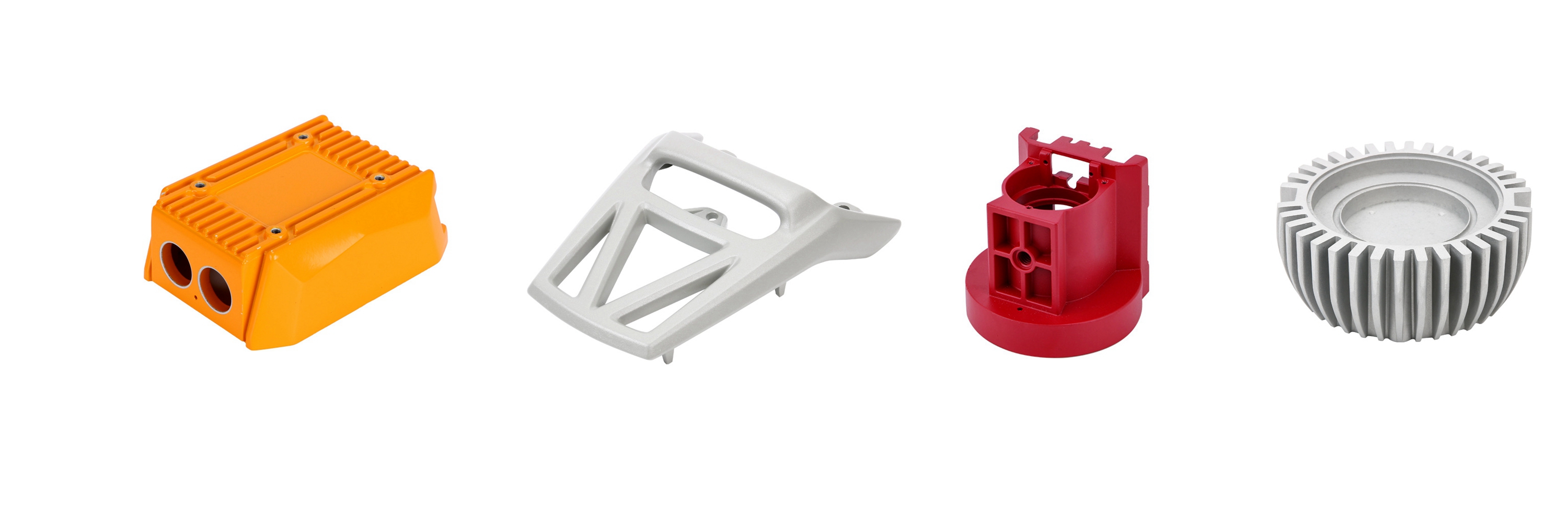

Properties of Assembling

Assembling involves combining materials like metals, plastics, and composites into final products or sub-assemblies. The process offers flexibility in texture, color, and surface finishes. Hardness, corrosion, and wear resistance depend on material choices and treatments. It's widely used for creating complex components and final products. Cost and time vary based on complexity and the number of parts involved.

Let's Start A New Project Today