Process | Primary Use | Material Options | Precision | Complexity | Finish Quality | Speed | Cost |

|---|

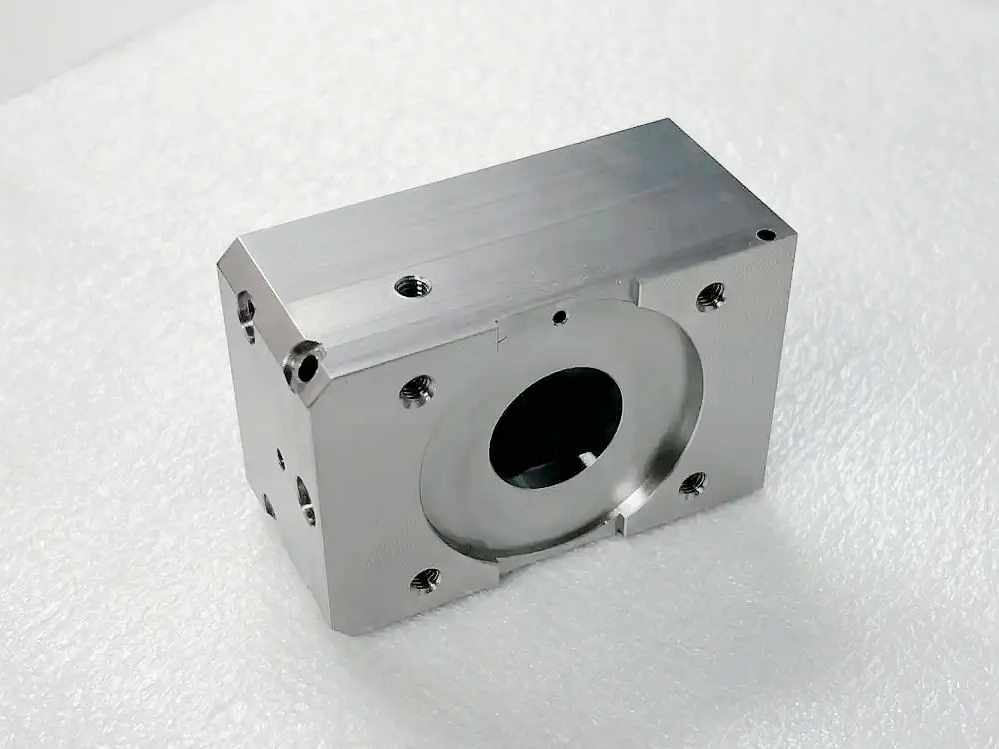

| CNC Machining | General machining for a wide range of parts | Metals (steel, aluminum, brass), plastics, composites (titanium, polymers) | ±0.01mm or better, depending on machine quality | Suitable for various shapes and geometries (2D, 3D, complex forms) | Smooth finish with minimal post-processing | Moderate to High (varies with complexity and material) | Moderate to High (higher cost for metals and tight tolerances) |

|

| CNC Milling | Cutting, drilling, and shaping parts | Metals (steel, aluminum), plastics, composites (titanium, brass) | Tolerances of ±0.005mm to ±0.02mm depending on tool and part complexity | Complex 3D shapes, slots, pockets, contours, and surfaces | Smooth finish with optional polishing or coating | High (dependent on part complexity and setup) | Moderate to High (cost increases with complexity and materials) |

|

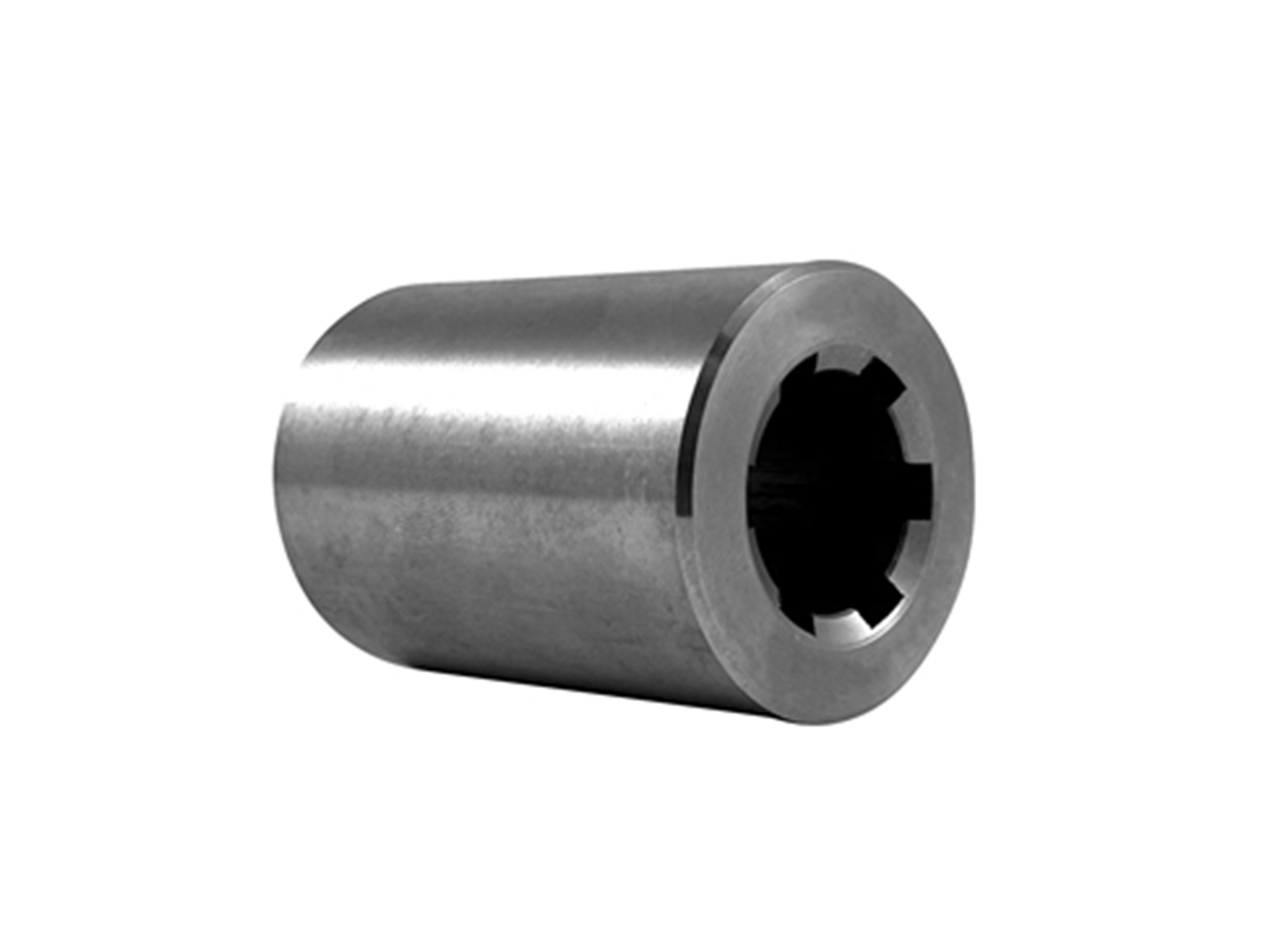

| CNC Turning | Shaping cylindrical parts | Metals (steel, aluminum, brass), plastics | ±0.01mm to ±0.02mm for typical turning tolerances | Best for parts with rotational symmetry, such as shafts, rings, and bushings | Smooth surface finish with limited post-processing required | Moderate (time for setup and part complexity) | Moderate (cheaper for simple parts, increases with materials) |

|

| CNC Drilling | Drilling holes and precise hole placement | Metals (steel, aluminum), plastics, composites | ±0.01mm or finer, depending on drill size and material | Focused on hole creation, with limited complexity outside hole depth/diameter | Fine hole finish, but may require polishing for very fine details | Fast | Low to Moderate (based on drill size and material) |

|

| CNC Boring | Enlarging or finishing pre-drilled holes | Metals (steel, aluminum), plastics | ±0.005mm or better (ideal for precise hole sizing) | Used for enlarging holes to exact dimensions | High-quality finish inside holes, no roughness | Moderate | Moderate (lower than grinding, depending on material) |

|

| CNC Grinding | Finishing parts to fine tolerances | Metals (steel, aluminum), ceramics, composites | ±0.001mm or better (extremely high precision) | Best for fine-tolerance and surface finish work, used on flat and cylindrical parts | Superior surface finish with minimal roughness and excellent flatness | Slow | High (due to slow process and precision required) |

|

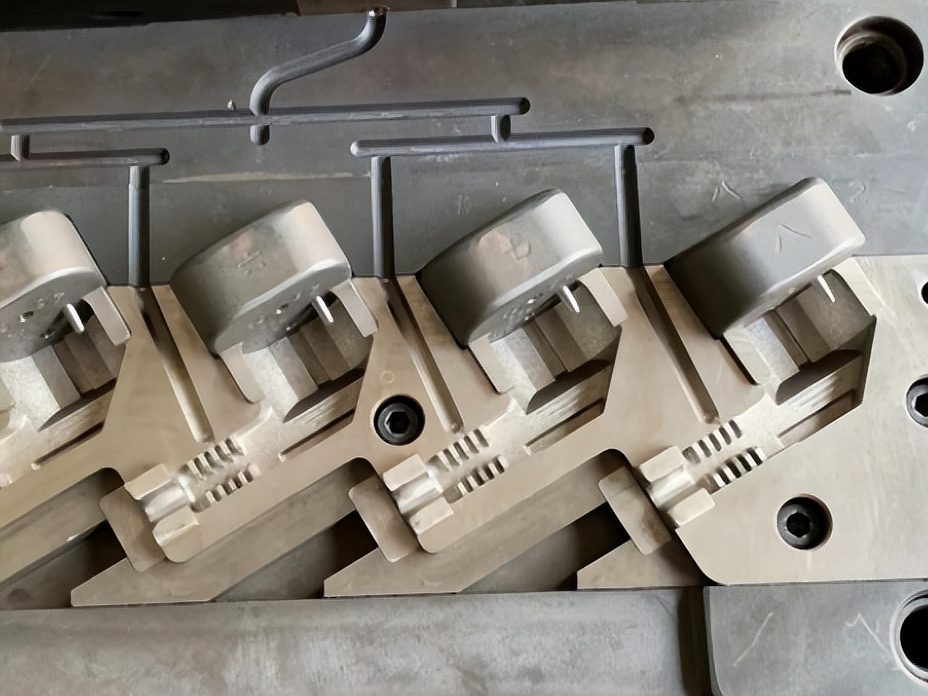

| Multi-Axis Machining | Complex geometries, 3D contours, and undercuts | Metals (steel, aluminum, titanium), plastics, composites | ±0.005mm to ±0.01mm (extremely tight tolerances for complex parts) | Capable of 5-axis (or more) simultaneous machining, ideal for intricate geometries, undercuts, and curved surfaces | High-quality finish, often requiring minimal post-processing | Slow to Moderate | High (complexity and tool wear contribute to cost) |

|

| Precision Machining | Extremely tight tolerances and complex parts | Metals (steel, aluminum, brass), ceramics, plastics | ±0.001mm or better (ultra-high precision) | Best for intricate, very fine parts, typically for aerospace, medical, and automotive industries | Exceptional finish quality, often ready-to-use without additional processing | Slow | High (high precision tools and longer time contribute to cost) |

|