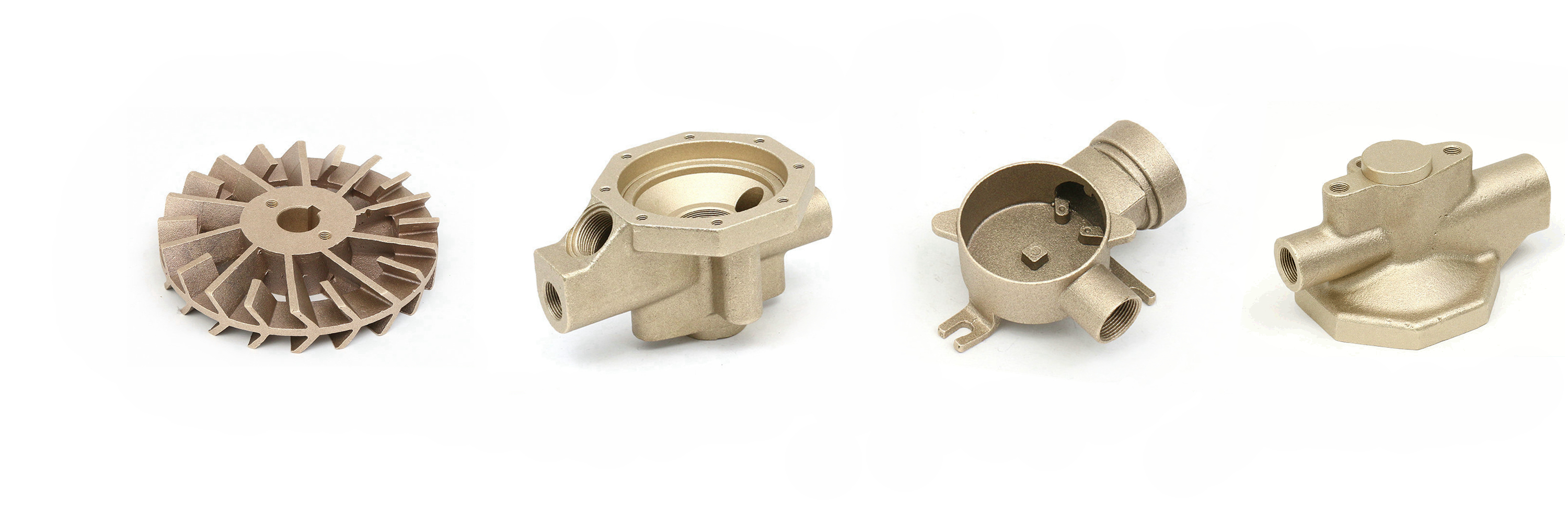

Typical Die Casting Copper/Brass Alloys

Typical Die Casting Copper/Brass Alloys are highly valued for their strength, durability, and excellent thermal conductivity. These alloys are ideal for applications requiring high corrosion resistance, good machinability, and aesthetic appeal, making them popular in industries like automotive, electronics, and decorative hardware.

- Superior Durability: Strong resistance to wear and corrosion.

- High Thermal Conductivity: Excellent heat dissipation properties.

- Excellent Machinability: Easy to process and shape.

- Aesthetic Appeal: Attractive finish for decorative applications.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

When To Choose Copper for Die Casting

Copper is an excellent choice for die casting due to its superior electrical and thermal conductivity, corrosion resistance, and strength. It is ideal for applications requiring high precision, durability, and excellent heat dissipation, such as electrical components, heat exchangers, and industrial equipment. Copper also offers a smooth finish and is highly resistant to wear and tear.

Typical Casting Copper/Brass Alloys

Typical Casting Copper/Brass Alloys** are widely used in die casting due to their strength, durability, and corrosion resistance. Popular alloys like C87600 (Bronze), C93200 (Bearing Bronze), and C36000 (Free-Cutting Brass) offer versatility for various industrial, automotive, and marine applications.

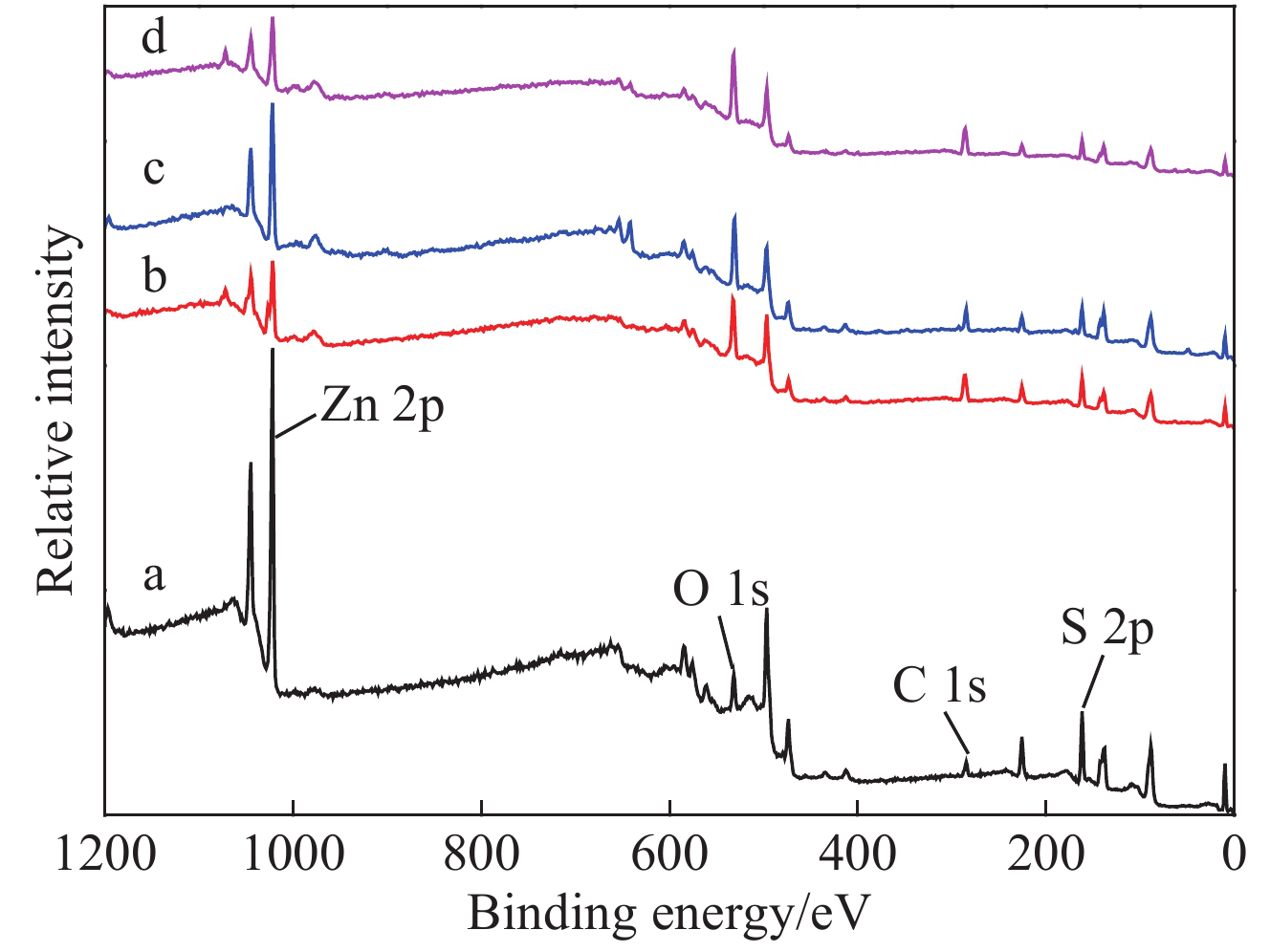

Typical Surface Treatment for Copper Castings

Typical surface treatments for copper castings include electroplating, powder coating, painting, polishing, shot blasting, vibratory finishing, chemical etching, clear coating, and PVD. These processes enhance properties such as corrosion resistance, surface hardness, appearance, and strength, while also improving durability and performance in various industrial applications.

Let's Start A New Project Today