Custom Online Copper Brass Die Casting Service

Explore our Custom Online Copper Brass Die Casting Service, offering high-quality metal casting, rapid prototyping, and post-process services. We provide a wide range of casting materials to meet your specific requirements and deliver precision-engineered solutions for your projects.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

What Is Copper/Brass Die Casting?

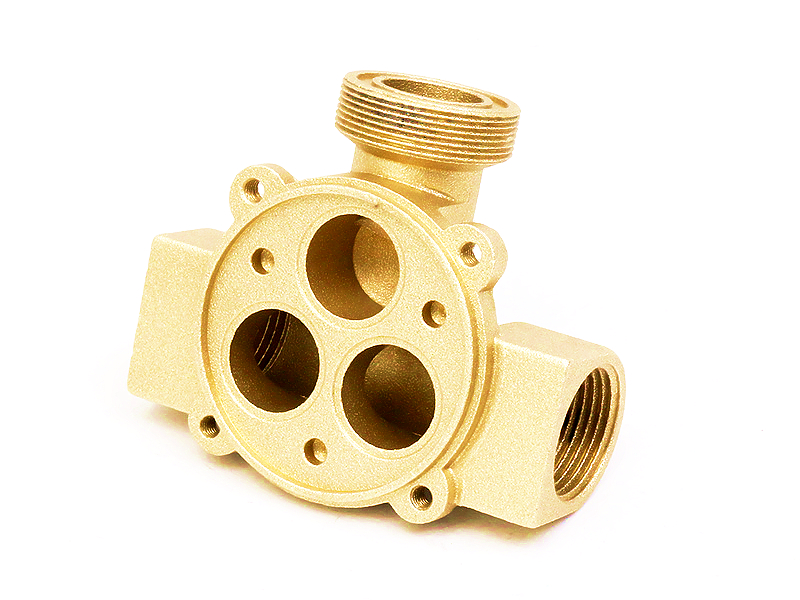

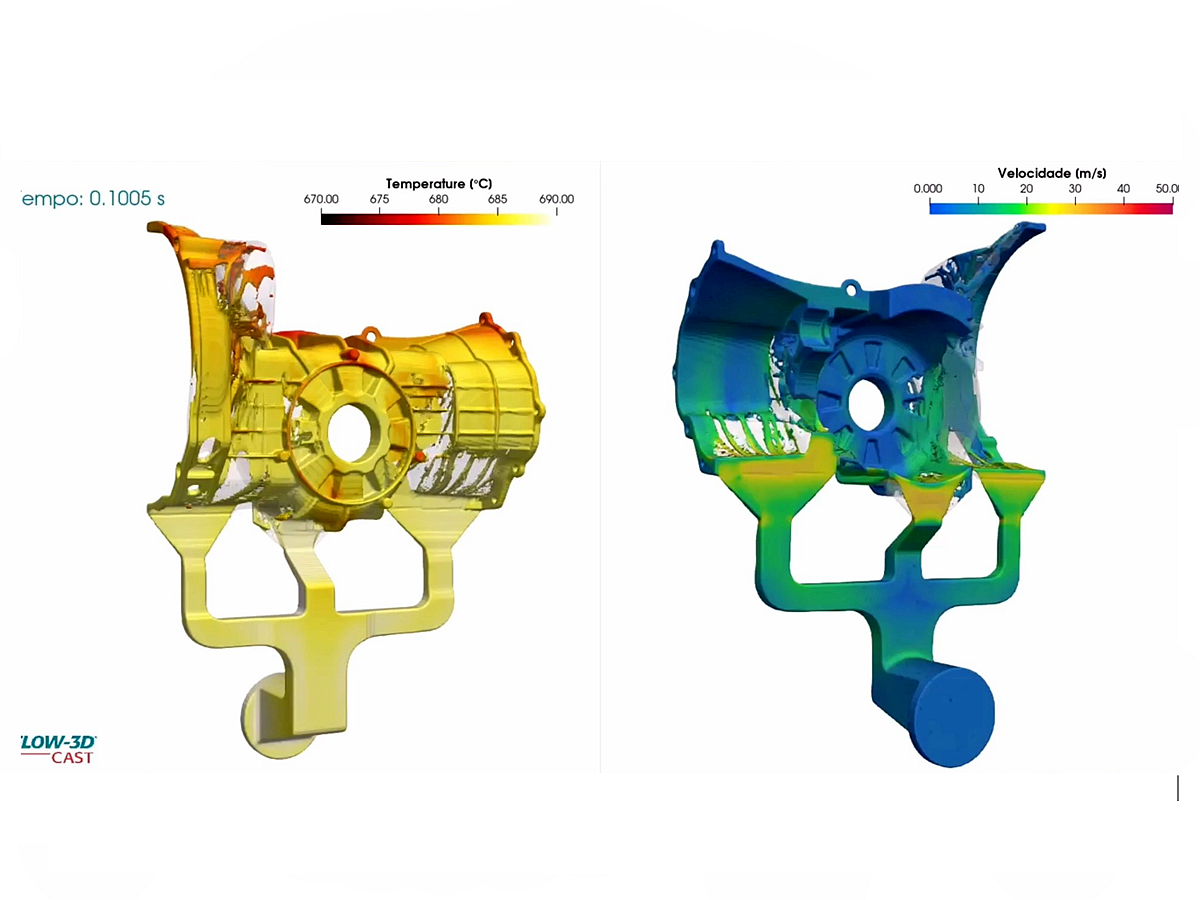

Copper/Brass die casting is a manufacturing process where molten copper or brass alloys are injected into molds under high pressure to create precise, durable parts. It's widely used in industries such as electrical, automotive, and plumbing due to its strength and conductivity.

Benefits of Copper/Brass Die Castings

Copper and brass die castings offer numerous benefits, including superior electrical conductivity, excellent corrosion resistance, high durability, and design flexibility. These advantages make them ideal for use in various industries such as automotive, electrical, plumbing, and aerospace applications.

Typical Casting Copper/Brass Alloys

Typical Casting Copper/Brass Alloys** are widely used in die casting due to their strength, durability, and corrosion resistance. Popular alloys like C87600 (Bronze), C93200 (Bearing Bronze), and C36000 (Free-Cutting Brass) offer versatility for various industrial, automotive, and marine applications.

Typical Surface Treatment for Copper Castings

Typical surface treatments for copper castings include electroplating, powder coating, painting, polishing, shot blasting, vibratory finishing, chemical etching, clear coating, and PVD. These processes enhance properties such as corrosion resistance, surface hardness, appearance, and strength, while also improving durability and performance in various industrial applications.

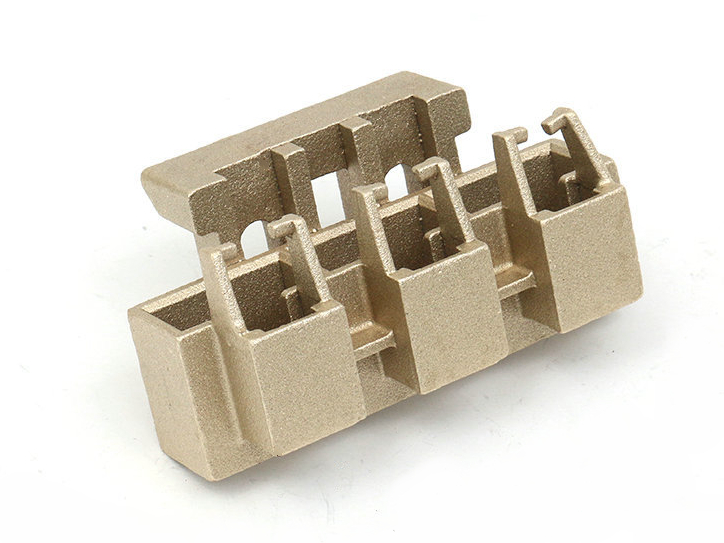

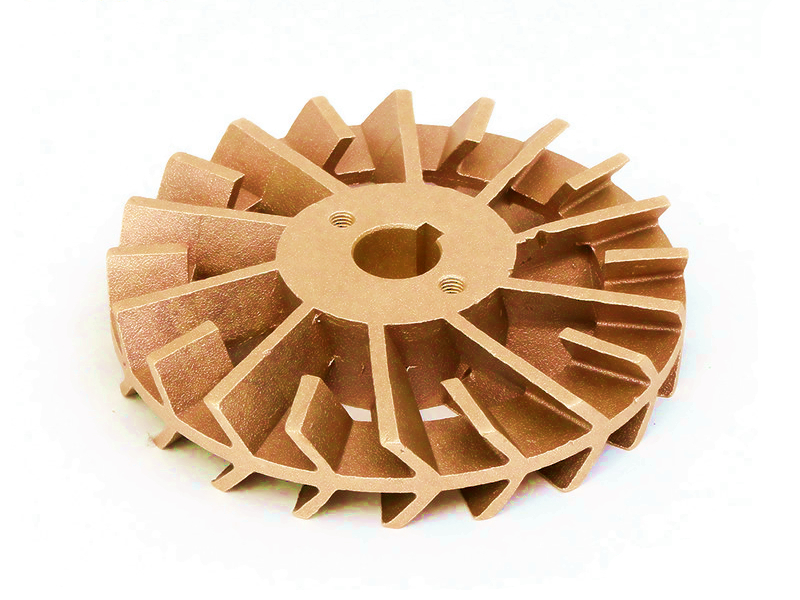

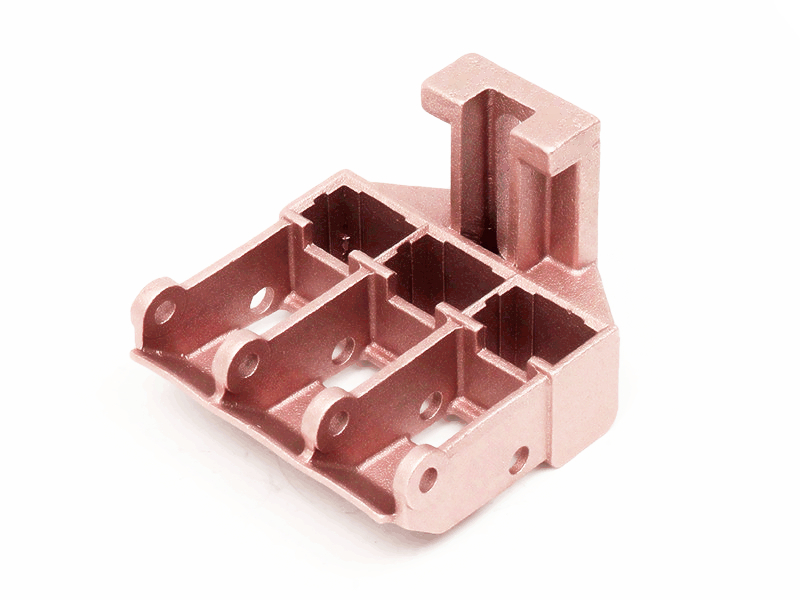

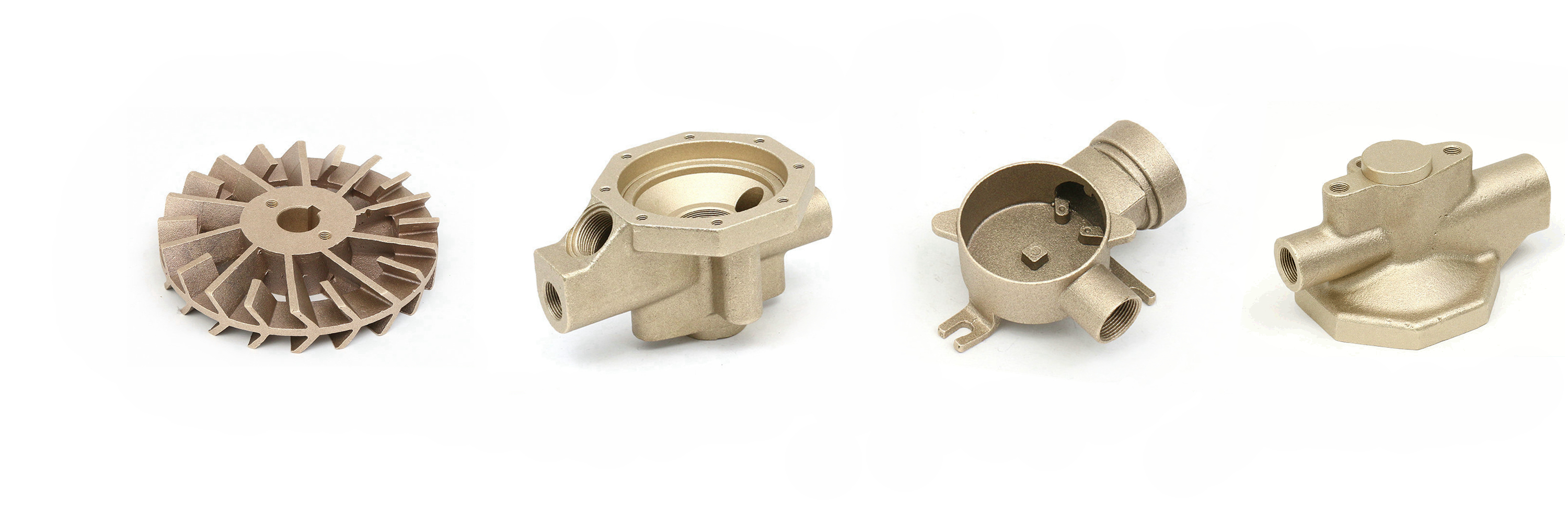

Applications of Copper and Brass Die Castings

Copper and brass die casting provide high-strength, corrosion-resistant solutions across industries. Ideal for electrical connectors, plumbing fittings, and HVAC heat exchangers, these alloys ensure durability and efficiency. From automotive cooling systems to pump components, mechanical hardware, and valve bodies, copper and brass die castings deliver precision and reliability in demanding applications.

Let's Start A New Project Today

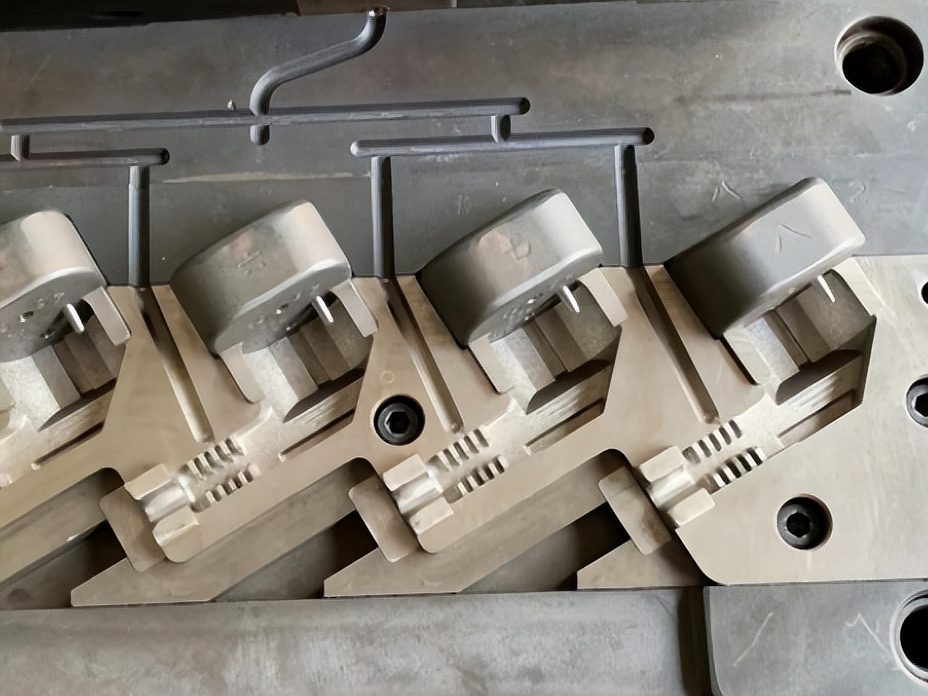

Copper Die Castings Design

A well-designed copper die casting ensures excellent durability, high thermal and electrical conductivity, and superior strength. It minimizes defects like porosity and improves material flow, reducing waste. Proper design allows for precise tolerances, enhances part integrity, and reduces the need for post-processing. This results in more efficient manufacturing, lower production costs, and higher-quality, long-lasting copper components.