What is the typical lead time for metal casting projects from design to production?

Understanding Lead Times in Metal Casting: From Design to Mass Production

In the manufacturing sector, lead time predictability is critical for aligning supply chains and minimizing time-to-market. For metal casting projects, the total duration from design finalization to first article delivery typically spans 7 to 16 weeks, influenced by four core phases: Design Validation, Tooling Development, Production, and Post-Processing. Below, we dissect each stage with technical benchmarks and strategies to accelerate timelines.

1. Design & Engineering Phase (2–4 Weeks)

Key Activities:

Design for Manufacturability (DFM) Analysis: Our Die Casting Design Service team conducts 3D simulation (e.g., MAGMAsoft®) to predict flow behavior, porosity risks, and thermal stresses. Modifications to wall thickness (ideal range: 1.5–5mm for aluminum) or draft angles (1–3°) often occur here.

Prototype Validation: Hybrid prototyping combining CNC Machining (for critical tolerances ±0.05mm) and 3D Printing (SLS/SLA for complex geometries) reduces iteration cycles by 40%.

Time-Saving Tip: Adopt concurrent engineering – overlap material testing (e.g., A380 Aluminum tensile tests) with mold concept design.

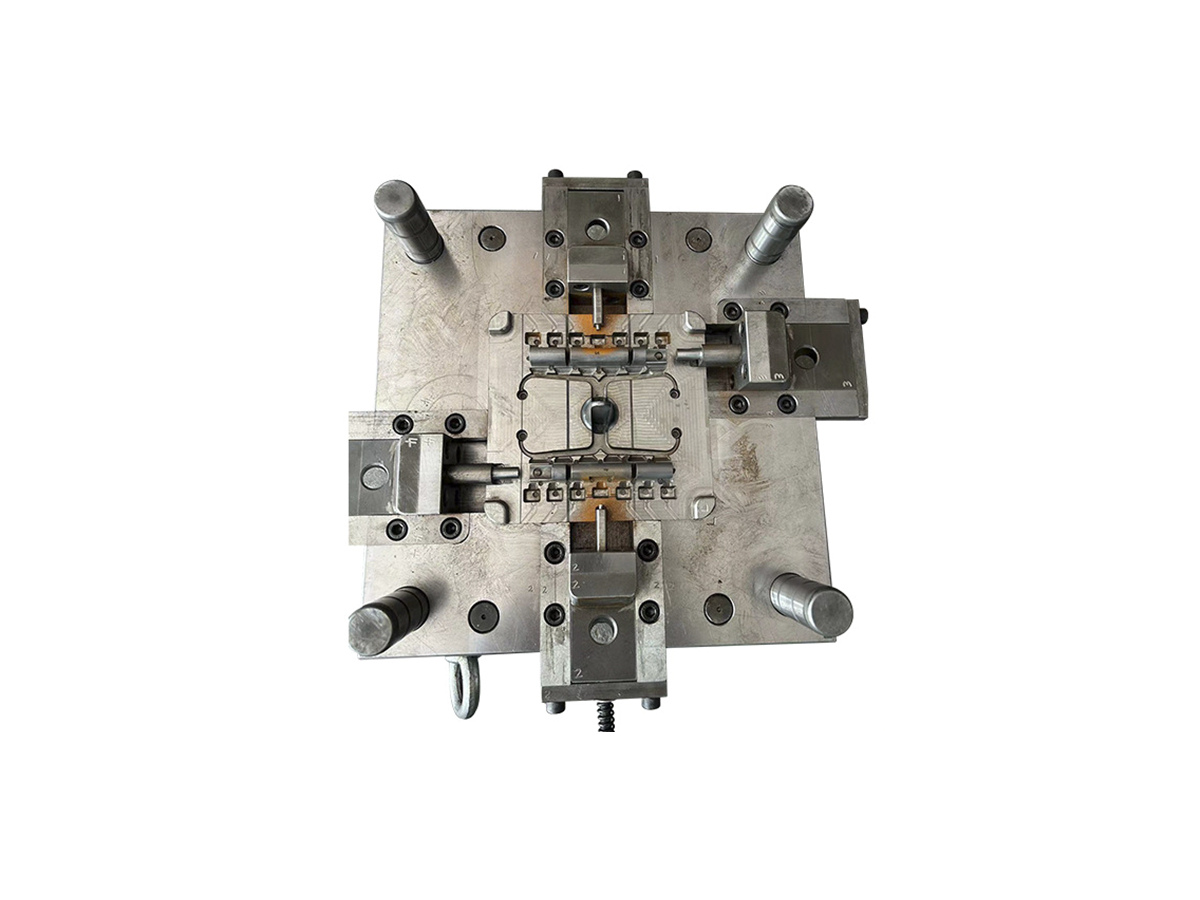

2. Tooling Development (3–8 Weeks)

Factors Impacting Duration:

Mold Material Selection:

H13 Hot-Work Steel: Requires 4–6 weeks for hardening (HRC 48–52) but offers 500,000+ cycles longevity.

Tungsten Carbide: 20% faster machining but 3× cost, ideal for micro-features (<0.2mm) in Zinc Die Casting.

Mold Complexity: Single-cavity tools: 3–4 weeks. Multi-cavity/multi-slide tools (e.g., automotive connectors): Up to 8 weeks.

Case Study: A medical device client reduced tooling time from 7 to 5 weeks using modular inserts (Tool Steel S7) for interchangeable core components.

3. Production & Post-Processing (2–4 Weeks)

Casting Operations:

High-Pressure Die Casting (HPDC): Cycle times range from 15 seconds (small zinc parts) to 2 minutes (large aluminum housings). Alloys like A360 enable faster fill rates (80 m/s) due to superior fluidity.

Secondary Processing:

Anodizing (Type II/III): Adds 3–5 days for corrosion-resistant layers (5–25μm).

Powder Coating: 2–3 days for electrostatic application and curing (180–200°C).

Critical Note: Post-machining (e.g., tapping M6 threads on Brass 360 components) may extend lead time by 1 week.

4. Quality Assurance (QA) & Certification (1 Week)

Testing Protocols:

CMM inspection (ISO 10360-2) for dimensional accuracy (±0.1mm standard).

X-ray (ASTM E155) to detect internal voids (<0.3% allowable porosity).

Certifications: IATF 16949 compliance for automotive clients adds 2–3 days for documentation.

Accelerating Timelines: Industry-Proven Strategies

One-Stop Service Integration Leverage our End-to-End Solution to synchronize prototyping, tooling, and production teams, reducing handover delays by 30%.

Standardized Alloy Libraries Pre-qualified materials like Zamak 5 (ZnAl4Cu1) eliminate 1–2 weeks of metallurgical testing.

Digital Twin Technology Real-time mold monitoring via IoT sensors cuts troubleshooting time by 50% during production ramp-up.

When to Expect Delays?

Design Changes Post-Tooling: Mid-process alterations (e.g., adding undercuts) extend lead time by 2–3 weeks.

Supply Chain Disruptions: Specialty alloys (e.g., CuNi10Fe1) may face 4-week procurement delays.