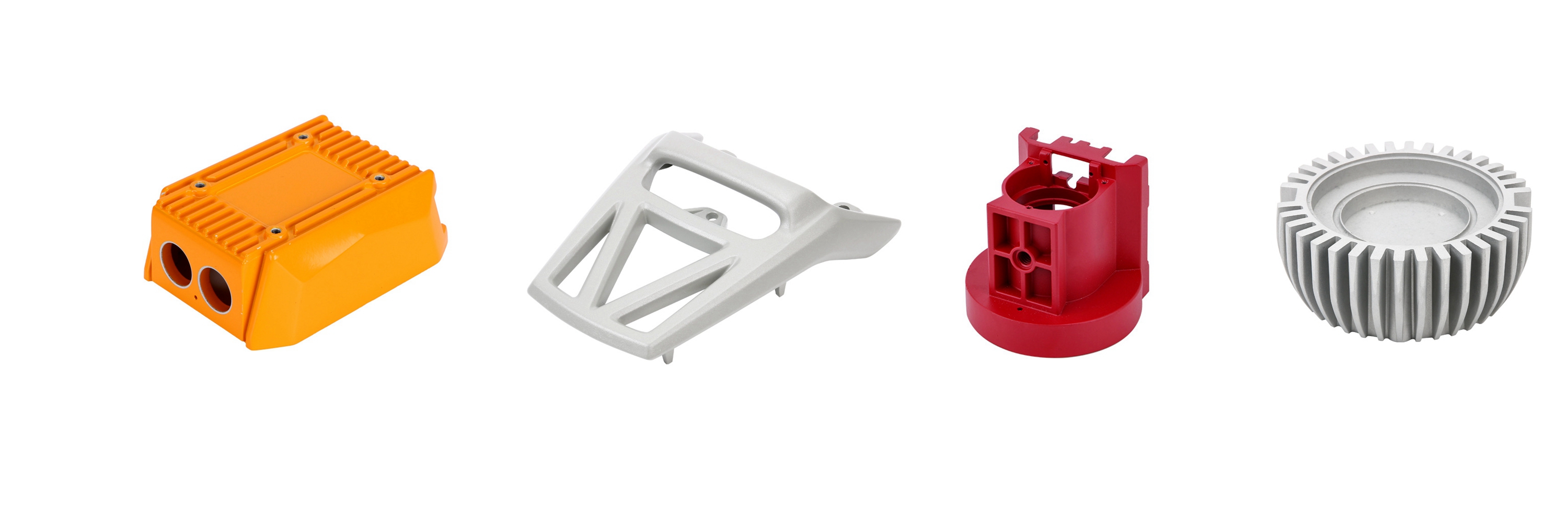

Painting Service For Die Castings

Painting Service for die castings involves applying a protective and decorative coating to the surface of die-cast parts. This process enhances the parts' appearance, provides corrosion resistance, and improves durability, ensuring that they meet both aesthetic and functional requirements.

- Enhanced Aesthetic Appeal: Provides a visually appealing finish.

- Corrosion Protection: Shields parts from environmental damage.

- Durability: Increases resistance to wear and scratches.

- Customization: Allows for color and texture variations.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

What Is Painting Service For Die Castings

Painting Service for die castings involves applying a protective and decorative coating to die-cast parts. This process enhances the parts’ appearance, provides corrosion resistance, and improves durability, ensuring a long-lasting, high-quality finish for both aesthetic and functional purposes.

Properties of Painting

Painting enhances the appearance and protection of materials like metals, plastics, and ceramics. It offers a wide range of color and texture options, with surface finishes ranging from matte to glossy. The process provides moderate to high hardness, corrosion, and environmental resistance. It’s commonly used in automotive, aerospace, and electronics industries, with moderate to high costs and processing times.

Let's Start A New Project Today