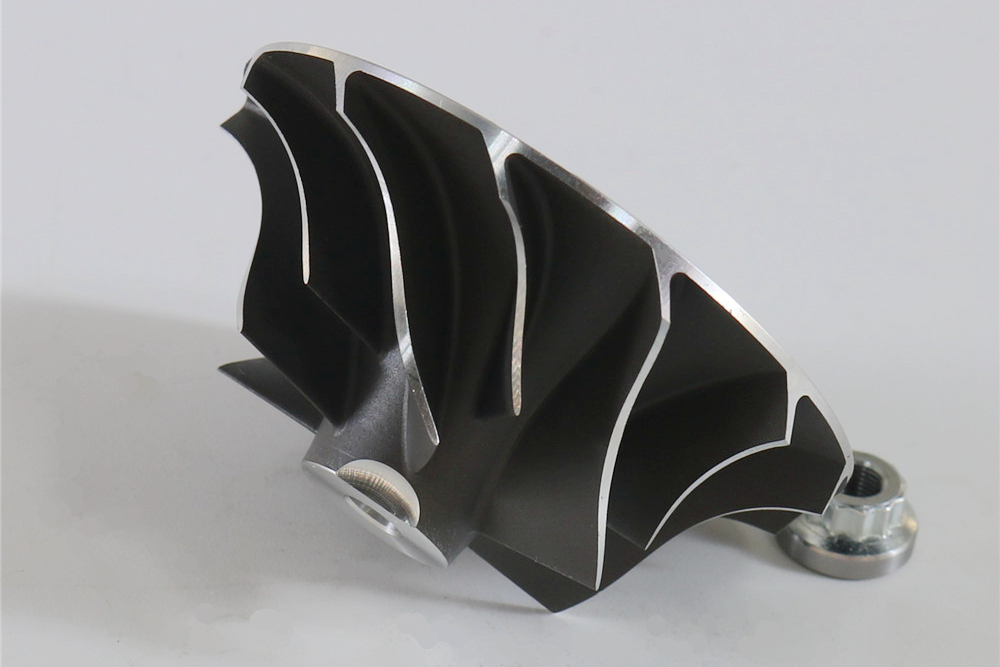

Post CNC Machining Service For Die Castings

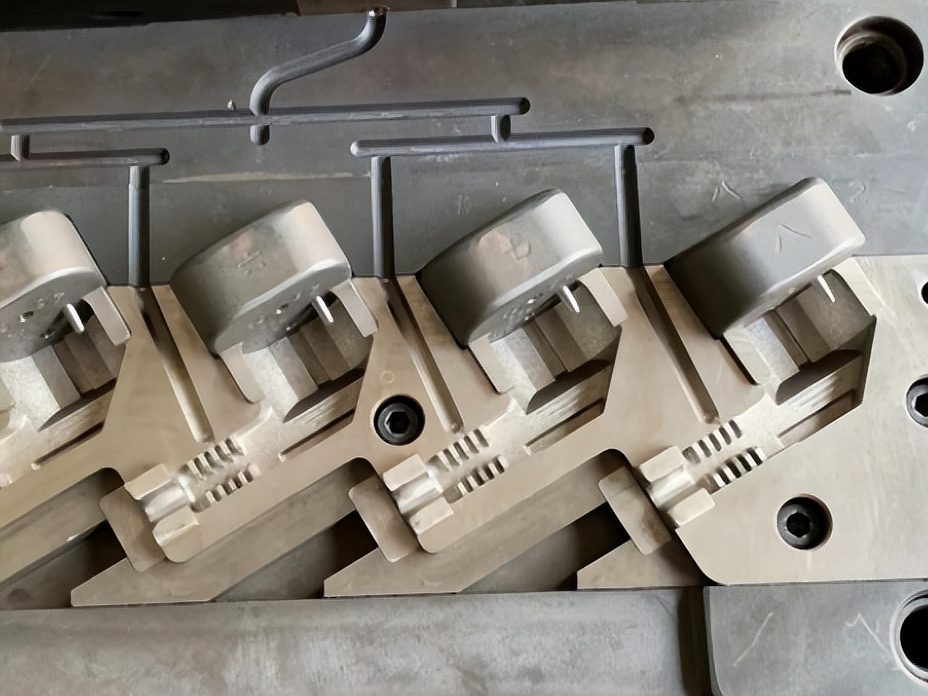

Post CNC Machining Service for die castings involves precision machining processes that refine die-cast parts after casting. This service enhances accuracy, surface finish, and customizability, ensuring that parts meet tight tolerances, improve functionality, and are ready for further assembly or use.

- Precision: Achieves tight tolerances and accuracy.

- Surface Finish: Enhances smoothness and appearance.

- Customization: Tailors parts to specific requirements.

- Efficiency: Reduces production time and cost.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

What Is Post CNC Machining Service For Die Castings

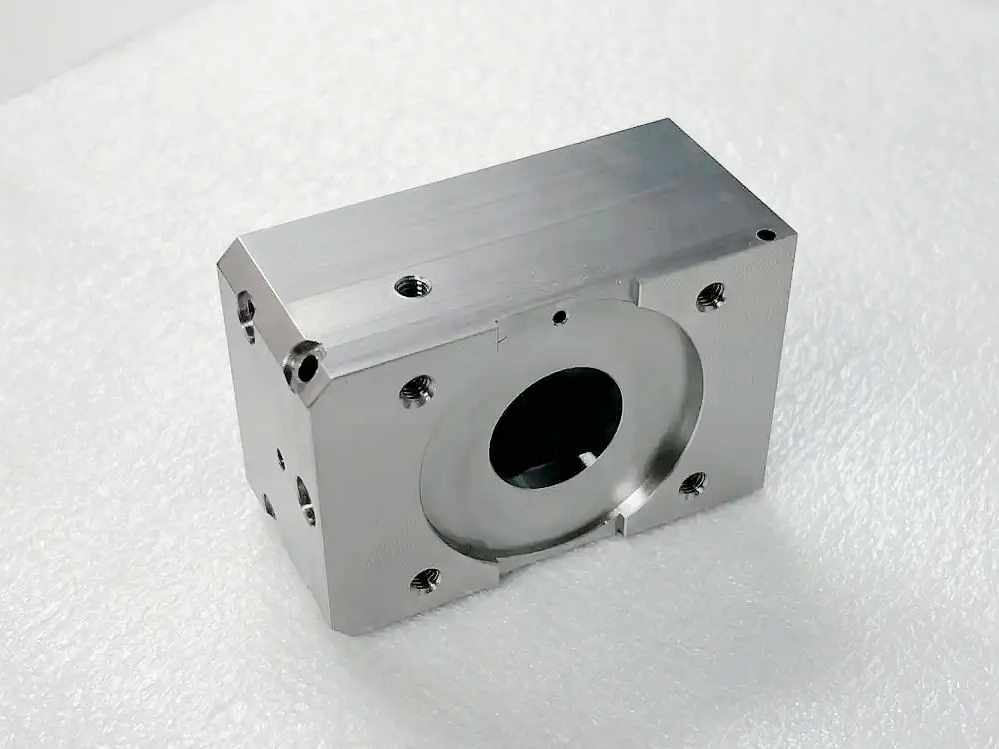

Post CNC Machining Service for die castings involves using advanced CNC machines to refine die-cast parts after the casting process. It ensures high precision, accurate dimensions, and superior surface finishes, making parts ready for final use or further assembly.

Properties of Post CNC Machining

Post CNC machining offers precise material compatibility, including metals, plastics, and composites, with surface finishes ranging from smooth to matte. It ensures excellent hardness, corrosion, and wear resistance, depending on the material and post-processing. Applications span industries like aerospace, automotive, and electronics. While the cost is moderate to high, it provides reliable quality and durability for complex parts.

Let's Start A New Project Today