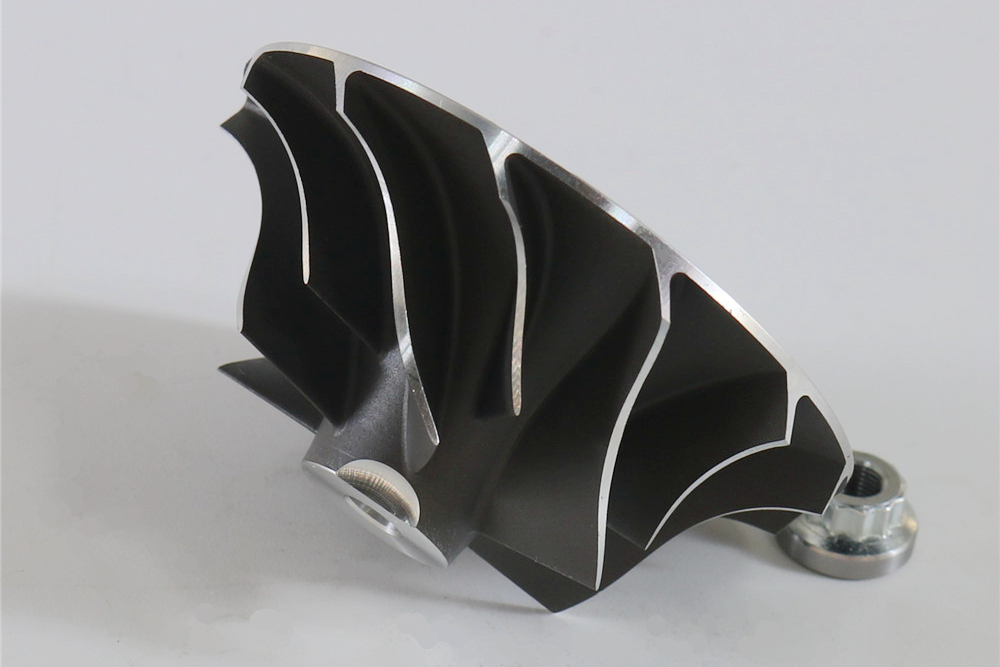

Post Process for Custom Die Castings

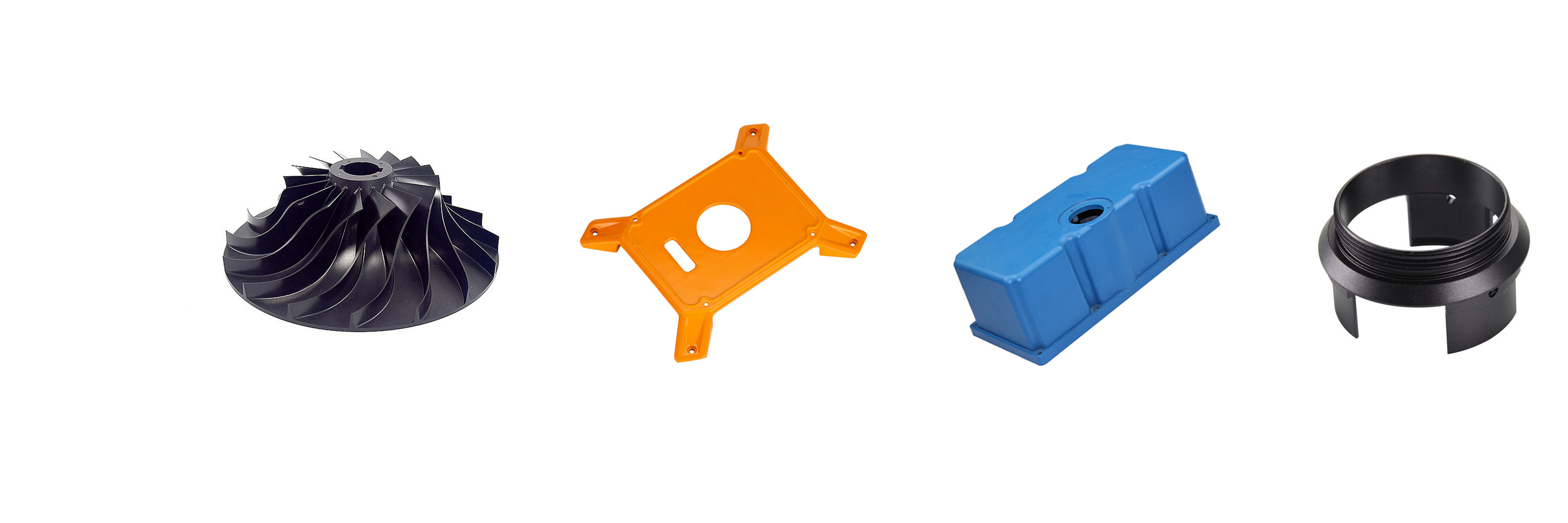

Our Post Process for Custom Die Castings includes essential finishing techniques like post machining, sand blasting, tumbling, assembling, painting, powder coating, anodizing, and arc anodizing. These processes improve surface quality, durability, and functionality, ensuring precision and enhanced performance for each part.

- Aluminum Castings Post Process

- Zinc Castings Post Process

- Copper Castings Post Process

- Tool and Die Post Process

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

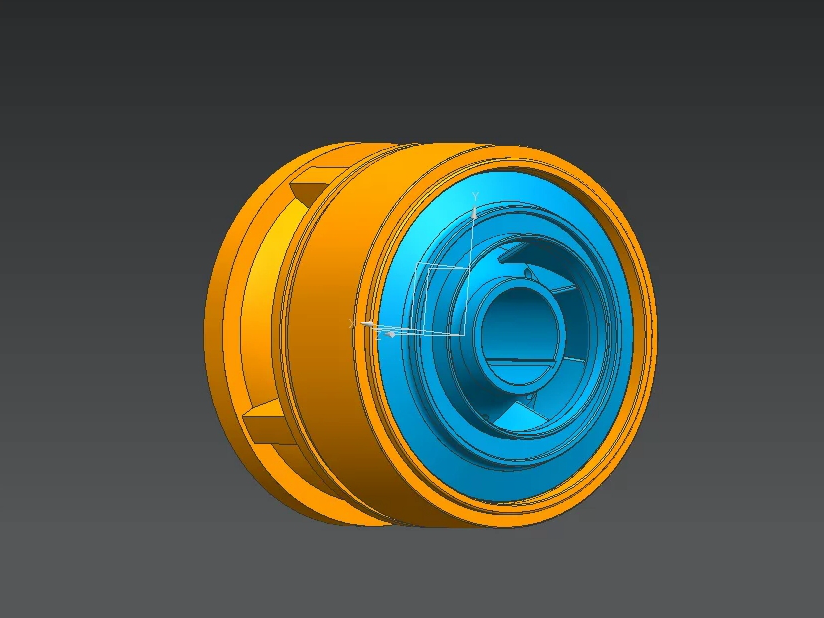

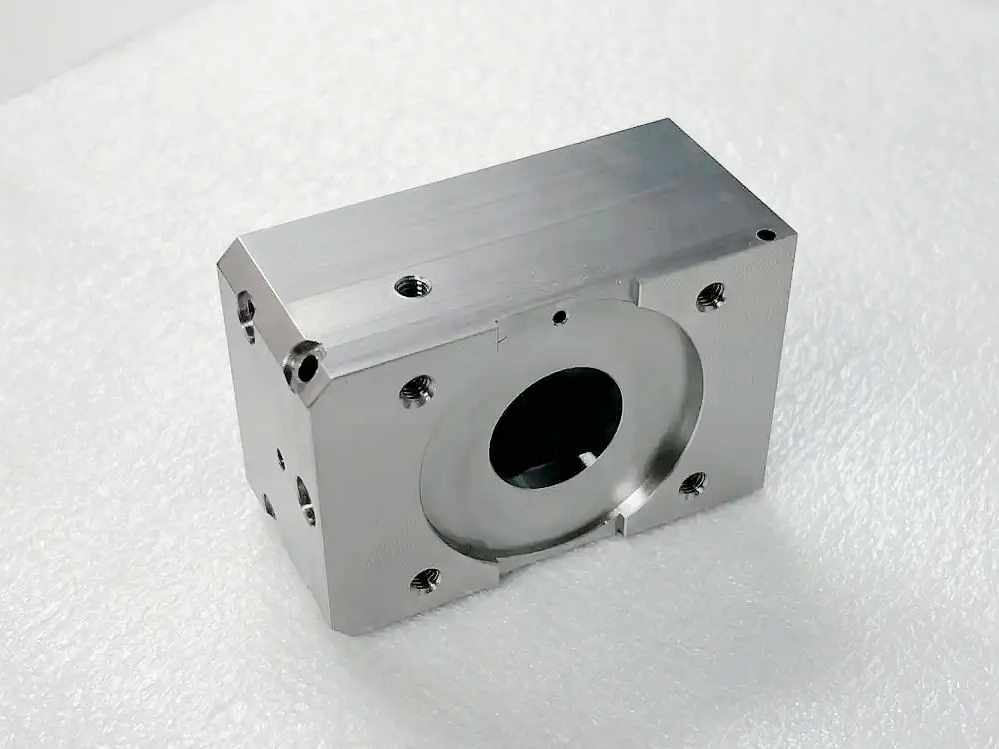

Typical Post Process for Die Castings

Typical post processes for die castings include post machining, sand blasting, tumbling, assembling, painting, powder coating, anodizing, and arc anodizing. These techniques refine surface quality, enhance durability, and improve part aesthetics, ensuring precision, functionality, and long-lasting performance for every casting.

Comparison of Post Processings

Post-processing methods vary based on material, application, and finish requirements. Techniques like sand blasting and tumbling are quick and cost-effective for cleaning and polishing. Anodizing and arc anodizing provide corrosion resistance, while powder coating and painting enhance durability and aesthetics. Post machining ensures tight tolerances. Each method balances speed, cost, and quality to suit different project needs.

Let's Start A New Project Today