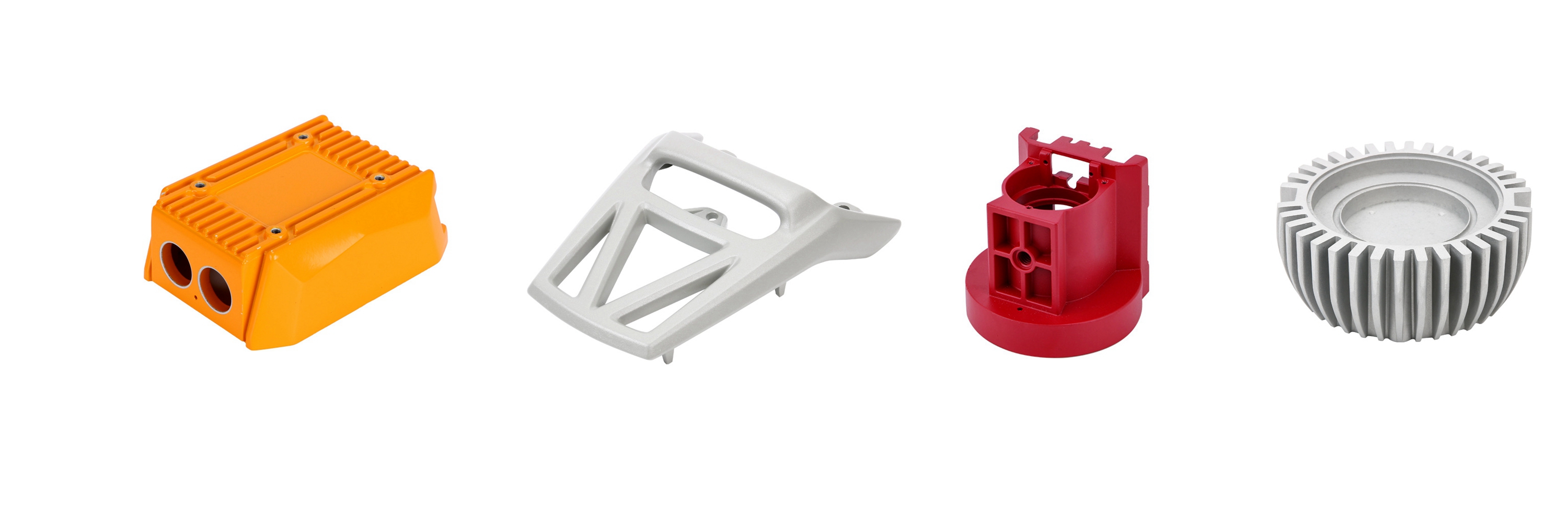

Powder Coating Service For Die Castings

Powder coating service for die castings involves applying a dry, powdered coating to metal parts using electrostatic charge. This method provides a durable, corrosion-resistant finish while offering a more eco-friendly solution compared to traditional liquid coatings, ensuring long-lasting protection.

- Durability: Offers long-lasting, scratch-resistant finish.

- Corrosion Resistance: Protects parts from environmental damage.

- Eco-Friendly: Contains no harmful solvents or VOCs.

- Uniform Coverage: Provides an even, smooth finish.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

What Is Powder Coating Service For Die Castings

Powder coating service for die castings is a process that applies a dry, powdered coating to metal parts using electrostatic charge. It creates a durable, corrosion-resistant finish, offering superior protection and aesthetic appeal while being more eco-friendly than traditional liquid coatings.

Properties of Powder Coating

Powder coating provides durable, high-quality finishes for metals, plastics, and ceramics. It offers a wide range of colors and textures, with excellent corrosion, environmental, and wear resistance. The process provides moderate to high hardness and good electrical insulation. Commonly used in automotive, industrial, and outdoor applications, it offers cost-effective, long-lasting protection with moderate processing time.

Let's Start A New Project Today