Custom Online Metal Parts Rapid Prototyping Service

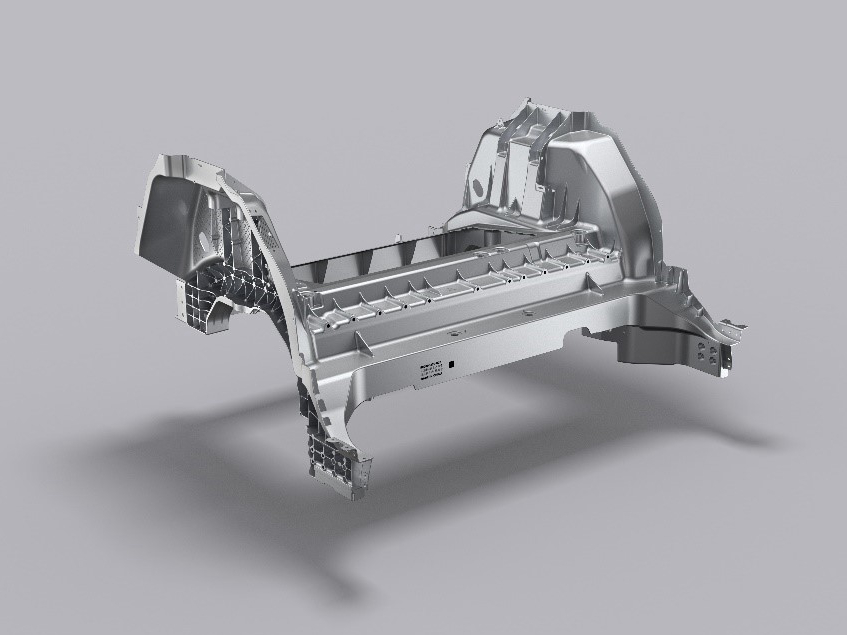

Our Custom Online Metal Parts Rapid Prototyping Service offers fast, high-quality prototypes using CNC machining, 3D printing, urethane casting, and sand casting. We ensure precise, functional parts with quick turnaround, enabling efficient design testing and development for various industries.

- Design Service

- Engineering Service

- Prototyping Service

- Low Volume Manufacturing Service

- Mass Production Service

- One-Stop Service

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

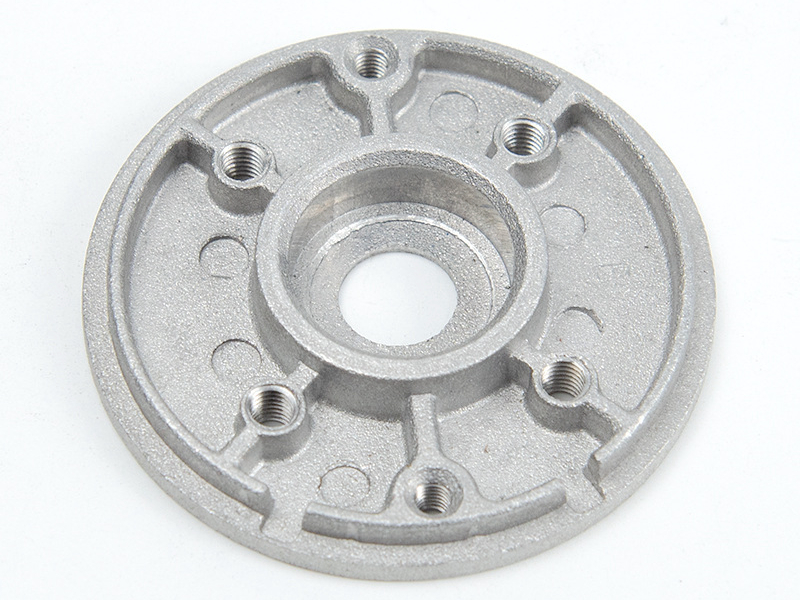

Custom Parts Rapid Prototyping Capabilities

Our Custom Parts Rapid Prototyping Capabilities utilize CNC machining, 3D printing, urethane casting, and sand casting to deliver fast, precise, and affordable prototypes. These advanced techniques ensure quick iterations and functional parts for diverse industrial applications.

How To Prototyping Service for Your Projects

To choose the right prototyping service for your project, consider factors like part complexity, material requirements, and production volume. CNC Machining offers high precision for various materials but may take more time for complex designs. 3D Printing is fast for intricate geometries and low-volume runs. Urethane Casting balances complexity and material options, while Sand Casting suits larger, simpler metal parts.

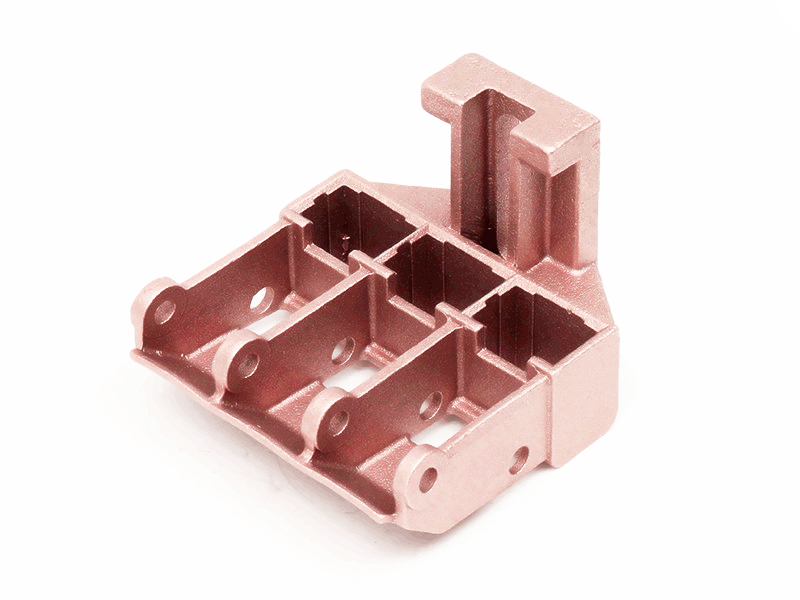

Post Process For Custom Parts

Our Post Process for Custom Parts includes a range of finishing services like post machining, sand blasting, tumbling, assembling, painting, powder coating, anodizing, and arc anodizing. These processes enhance part durability, aesthetics, and functionality, ensuring high-quality, precise results.

Let's Start A New Project Today