Are design modifications possible during the prototyping phase?

Yes, design modifications are possible and expected during the prototyping phase, especially in industrial applications where functionality, structural integrity, and manufacturability must be rigorously validated. Prototyping is a controlled environment to test and refine part geometry, material selection, and dimensional tolerances before committing to permanent tooling. At Neway, we support iterative design updates through agile prototyping methods such as urethane casting, sand casting, 3D printed patterns, and soft die casting tooling.

The Engineering Purpose of Prototyping Iteration

Despite high-resolution CAD modeling and FEA simulation, physical prototypes often reveal real-world performance issues that are otherwise difficult to predict. These may include:

Inadequate wall thickness (<2 mm for aluminum A380 parts), causing incomplete fill or warping

Assembly interference due to tolerance stack-up or unaccounted hardware

Localized stress concentrations identified through fatigue testing or drop impact

Surface defect susceptibility during powder coating or anodizing

Industry standards such as ISO 8062 (for casting tolerances) and ISO 2768 (for general machining) guide acceptable limits during design validation, but adjustments are often needed based on real part behavior.

Flexibility of Design Modifications by Process

Prototyping Method | Modification Agility | Design Change Turnaround | Recommended Applications |

|---|---|---|---|

3D Printing (Plastic/Resin) | Very High | Same day to 2 business days | Master pattern generation, visual mock-ups, fit testing |

Urethane Casting | High (via master model swap) | 3–5 business days | Low-load enclosures, quick-turn concept validation |

Sand Casting | Medium–High | 5–10 business days (pattern or core reprint) | Complex aluminum or bronze geometries, mechanical testing |

Low-Volume Die Casting | Medium | 1–2 weeks (tool insert modification) | Pre-production validation, field test batches |

These technologies allow Neway to implement modifications quickly, often without full tooling replacement. For instance, updating draft angles from 0.5° to 2° can significantly improve demolding and extend mold life, with minimal change to part function.

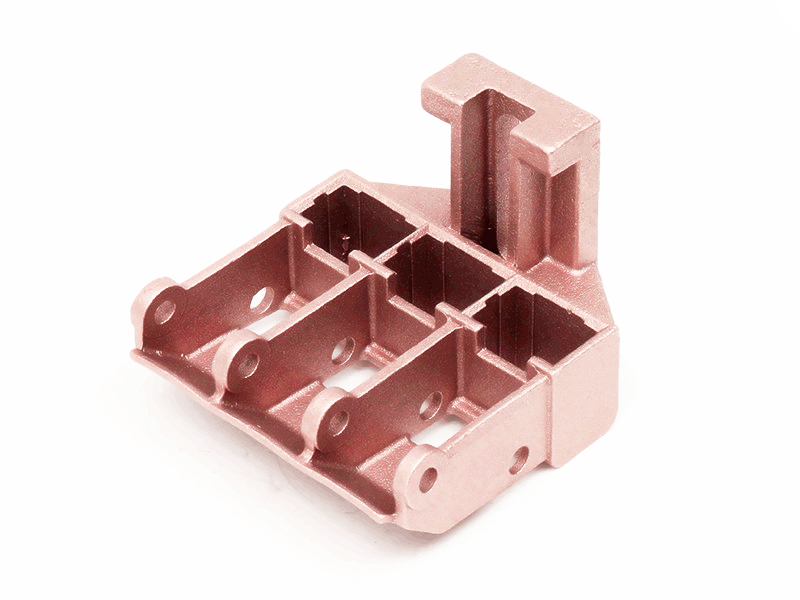

Common Types of Design Revisions in Prototyping

Wall Thickness Optimization: Adjusting from 1.5 mm to ≥2.5 mm in aluminum die castings (e.g., A380 alloy) improves mold fill and thermal performance

Fillet Radius Insertion: Adding 1.5–3 mm radii reduces stress concentration factor (Kt) by up to 40% in corner-loaded areas

Rib Structure Rework: Modifying height-to-thickness ratio to ~3:1 improves stiffness while preventing sink marks

Draft Angle Tuning: Increasing from 0.5° to 1.5° per ISO 1302 guidelines facilitates better tool release in zinc die castings

Tolerance Refinement: Transitioning from ±0.3 mm (ISO CT7) to ±0.1 mm (CT6) for machined interfaces requiring CNC post-processing

Depending on environmental and thermal testing feedback, design iterations can also include integration of features like cable bosses, pressure relief vents, or heat-dissipation fins.

Engineering Collaboration Throughout the Iteration Cycle

Neway’s engineering team provides ongoing support throughout the prototyping and modification process, including:

Design for Casting and Machinability (DFM) reviews aligned with ISO 8062 and DIN EN 1706

Simulation-based gate and flow optimization, especially for thin-wall aluminum components (<3 mm)

Surface finish strategy matching, based on end-use coating method (e.g., Rz ≤ 10 µm for anodizing)

Material compatibility advice for structural, conductive, or corrosion-sensitive parts

These services help ensure that prototypes do not only validate geometry but also serve as functional models for production readiness.

Case Study: Iterative Modification for Die Cast Lighting Frame

A client designing a weatherproof LED fixture initially prototyped 10 parts via urethane casting to evaluate mechanical assembly. Based on field input, Neway adjusted ventilation slot length, added M4 boss inserts, and updated internal support ribs. Within 7 working days, updated master models were printed and new silicone molds were cast. Upon validation, the design was transitioned to AlSi12 low-volume aluminum die casting for corrosion-resistant pre-series parts.

This test, revision, and validation cycle allowed the client to move to certification testing without delay or tooling scrap.

Conclusion

Design modifications are not only feasible but essential during the prototyping phase. Neway's integrated prototyping platform enables rapid, data-driven design evolution, whether you're making dimensional adjustments, mechanical improvements, or surface refinements. Our flexible processes—backed by industry standards and real-world testing—ensure your final design is functionally optimized, manufacturable, and market-ready.