What’s the difference between rapid prototyping and bridge tooling?

When moving a product from concept to production, manufacturers must validate form, fit, and function before committing to high-volume tooling. Two key strategies in this transitional phase are rapid prototyping and bridge tooling. While both are vital for early-stage development, they serve different purposes and are suited for other volumes, lead times, and production goals.

At Neway, we support rapid prototyping and bridge tooling solutions, helping customers reduce risk and accelerate time to market with cost-effective, scalable options.

What Is Rapid Prototyping?

Rapid prototyping refers to fast, low-volume production of test parts using temporary or no tooling. It lets engineers quickly evaluate part geometry, design flaws, assembly fit, and basic functional characteristics. Methods commonly used at Neway include:

Urethane casting from silicone molds

3D printing (for patterns or direct-use parts)

Quick-pour sand casting with printed cores

CNC machining from billet metals

Rapid prototyping is ideal for quantities from 1 to 20 pieces and is often completed in 7 to 15 business days, depending on part complexity.

What Is Bridge Tooling?

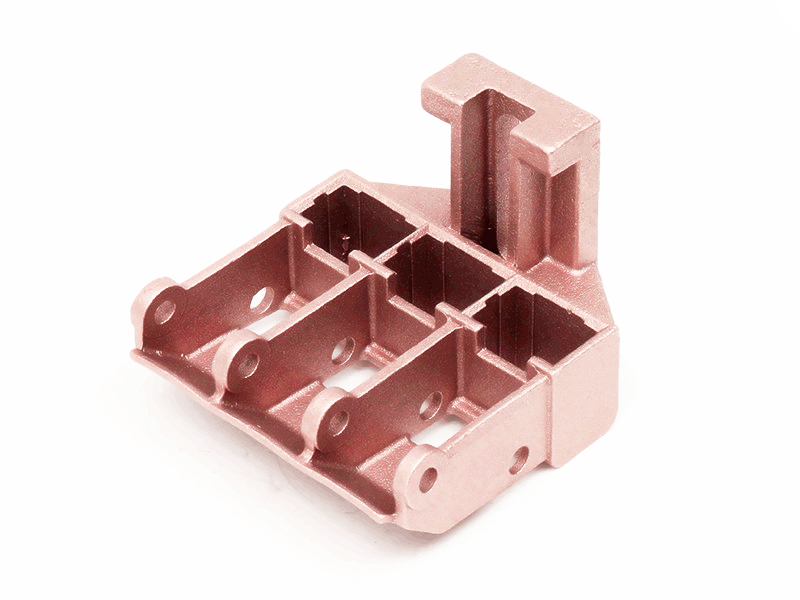

Bridge tooling—also known as soft tooling—is a low-cost, short-life version of production tooling, used to fill the gap between prototyping and full-scale manufacturing. It’s built using less durable materials (like aluminum or pre-hardened steel) and optimized for fast turnaround and moderate output.

At Neway, bridge tooling is often used in low-volume die casting when producing 100 to 10,000 units before full investment in hardened tool steel molds. It allows functional validation with final materials and processes, enabling performance testing, market trials, or pilot production.

Key Differences Between Rapid Prototyping and Bridge Tooling

Criteria | Rapid Prototyping | Bridge Tooling |

|---|---|---|

Typical Quantity Range | 1–20 units | 100–10,000 units |

Lead Time | 5–15 business days | 3–6 weeks |

Tooling Material | None or silicone/printed molds | Aluminum, pre-hardened steel |

Part Material | Substitute or partial-performance materials | Final production alloys (e.g., A380, Zamak 5) |

Surface Finish | Rough to cosmetic | Comparable to production quality |

Use Case | Design validation, mock-ups, early-stage testing | Pilot runs, regulatory testing, short-term production |

Cost Per Unit | Higher (especially for metals) | Lower for moderate volumes |

When to Use Rapid Prototyping

Rapid prototyping is best suited for early-stage product development when speed, iteration, and low investment are the priorities. It helps identify and resolve:

Geometry conflicts or assembly misalignment

Ergonomic issues or component interference

Enclosure packaging before electronics integration

For example, an early-phase aluminum die cast housing prototype may be CNC machined from a billet or produced via sand casting for rapid design review.

When to Use Bridge Tooling

Bridge tooling is used when production-like parts are needed for:

Mechanical testing under actual stress loads

Surface finishing, coating, and corrosion resistance evaluations

Interim supply during final tool build or design freeze

Small-scale launch before full mass production

A great example is producing 1000 units of a Zamak 5 connector body for pilot deployment in consumer electronics.

Can Both Be Used Together?

Yes, and they often are. Many development roadmaps start with rapid prototyping to verify form and function, then shift to bridge tooling to meet short-term production or field testing needs before transitioning to high-volume production tooling.

Neway’s integrated approach allows seamless movement between these stages, ensuring consistent quality, traceability, and minimal disruption.

Conclusion

The difference between rapid prototyping and bridge tooling is speed vs. scale. Rapid prototyping excels in fast, flexible iterations at the earliest design phases, while bridge tooling fills the gap between prototype validation and full-scale production. Both are essential tools in modern product development, and at Neway, we help you select the most effective approach for your project's timeline, volume, and performance requirements.