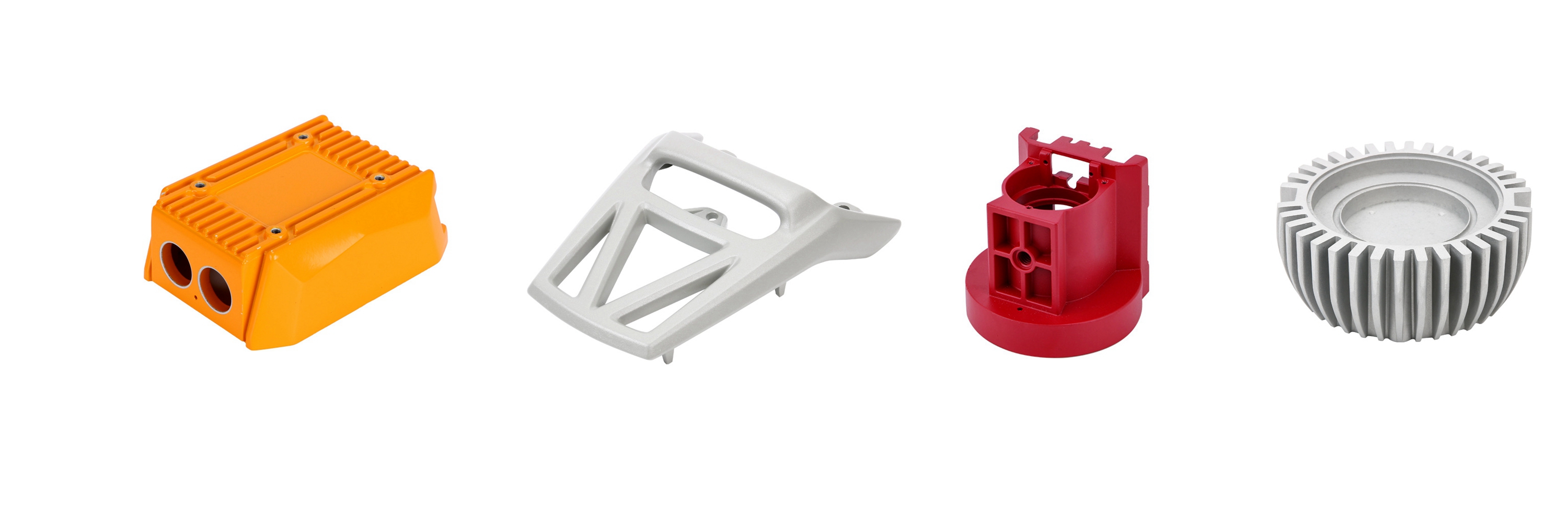

Sand Blasting Service For Die Castings

Sand Blasting Service for die castings uses abrasive materials to clean, smooth, and enhance the surface of die-cast parts. This process removes contaminants, roughens surfaces for better coating adhesion, and improves the overall aesthetic quality of the final product.

- Surface Cleaning: Removes contaminants for better adhesion.

- Surface Roughening: Enhances coating bond strength.

- Deburring: Smooths sharp edges and burrs.

- Aesthetic Finish: Improves appearance and texture consistency.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

What Is Sand Blasting Service For Die Castings

Sand Blasting Service for die castings is an abrasive cleaning process that removes contaminants, roughens surfaces, and enhances the texture of die-cast parts. It prepares components for further processing, such as coating or painting, improving adhesion and final appearance.

Properties of Sand Blasting

Sand blasting is a surface treatment process used for cleaning, texturing, or preparing parts for further coating. It works on metals, plastics, ceramics, and glass, providing matte to textured finishes with surface roughness (Ra 3.2 - 6.3 µm). It improves corrosion resistance when combined with coatings, offers moderate wear resistance, and is cost-effective and fast.

Let's Start A New Project Today