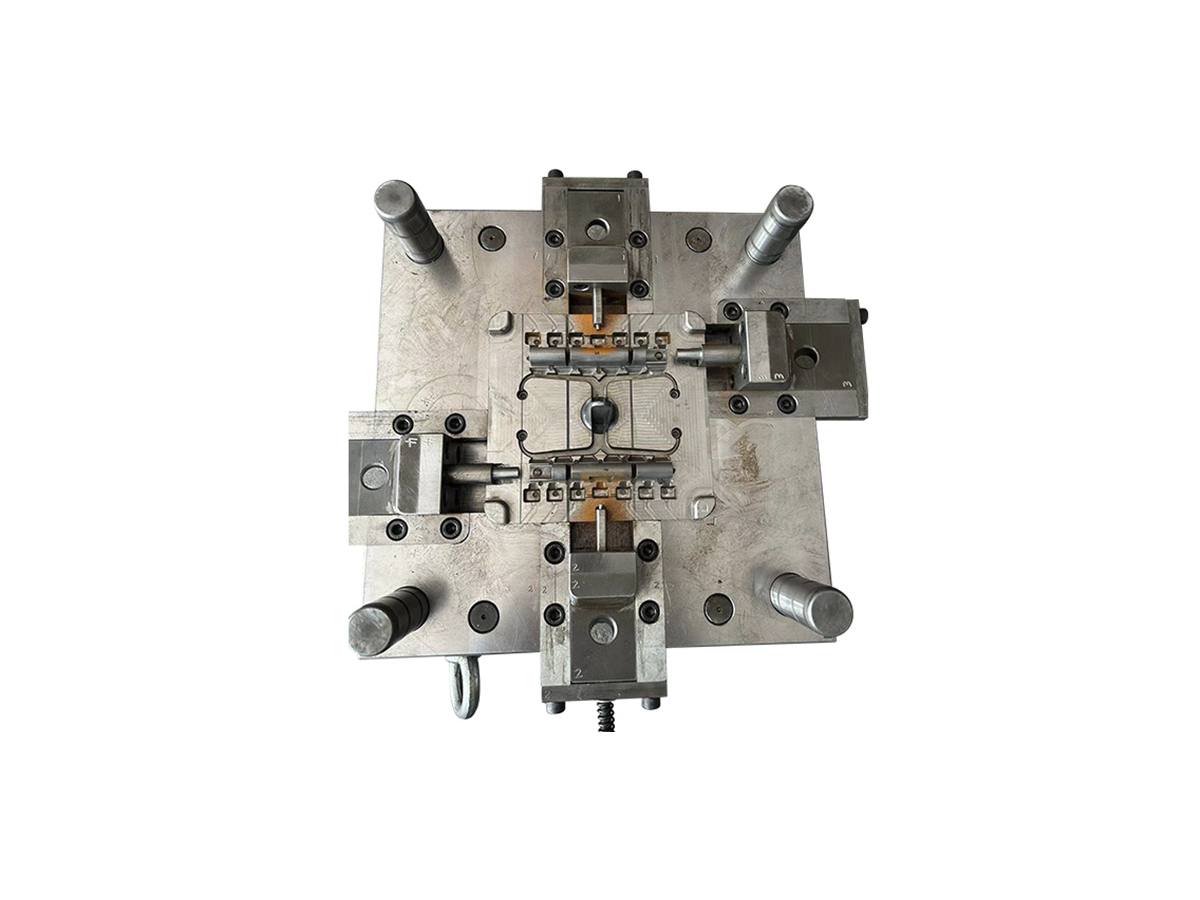

Typical Die Casting Tool and Die Materials

Typical Die Casting Tool and Die Materials are specially engineered for strength, precision, and durability. These materials, such as steel and carbide, are designed to withstand the high pressures and temperatures of die casting, ensuring long-term performance and high-quality part production.

- High Durability: Ensures long-lasting tool performance.

- Precision: Delivers accurate, detailed die-cast parts.

- Heat Resistance: Withstands extreme temperatures during casting.

- Cost-Effective: Reduces production costs and tool wear.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

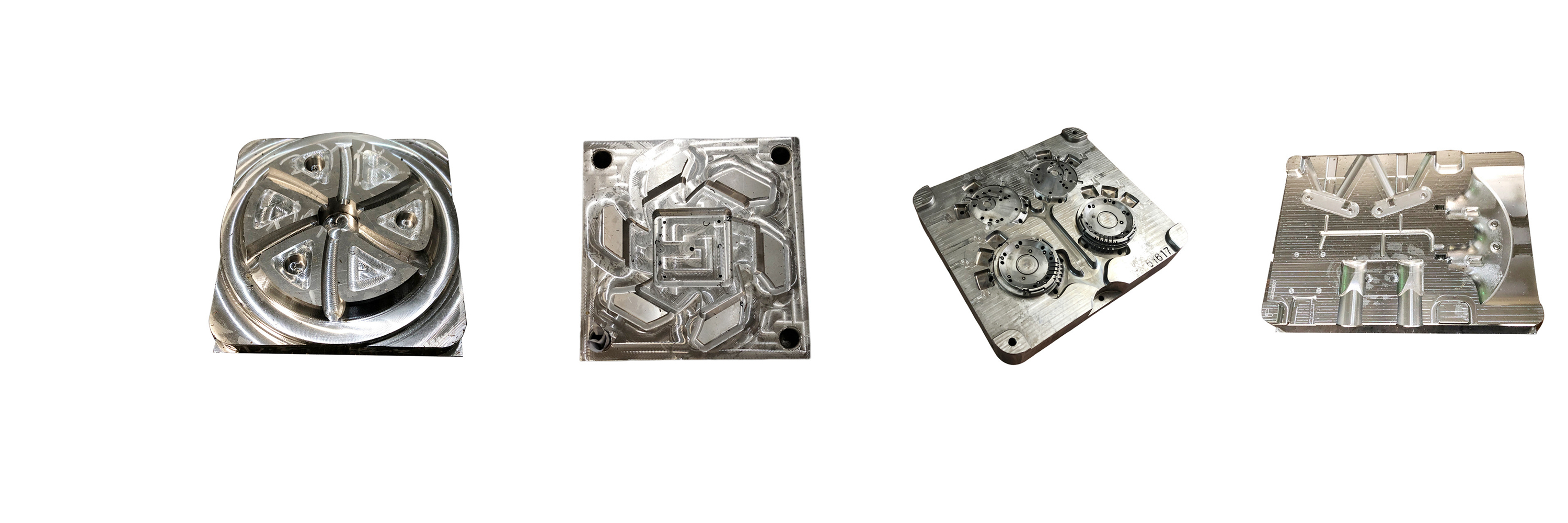

How To Choose the Tool and Die Materials

Selecting the right tool and die materials is essential for achieving durability, precision, and performance in die casting and other manufacturing processes. Materials such as H13 Steel, P20 Steel, D2 Steel, and A2 Steel offer different benefits, from high-temperature resistance to wear and corrosion resistance. Beryllium Copper, Tungsten Carbide, and Inconel 718 are also vital choices for applications requiring high strength, heat resistance, and corrosion resistance.

Typical Materials of Tool and Die

Typical materials for tool and die-making include high-strength steels like H13, P20, D2, and A2, as well as Beryllium Copper and Tungsten Carbide. These materials offer excellent wear resistance, shock resistance, and high-temperature performance, making them ideal for creating durable molds and tools used in die casting, injection molding, and other manufacturing processes.

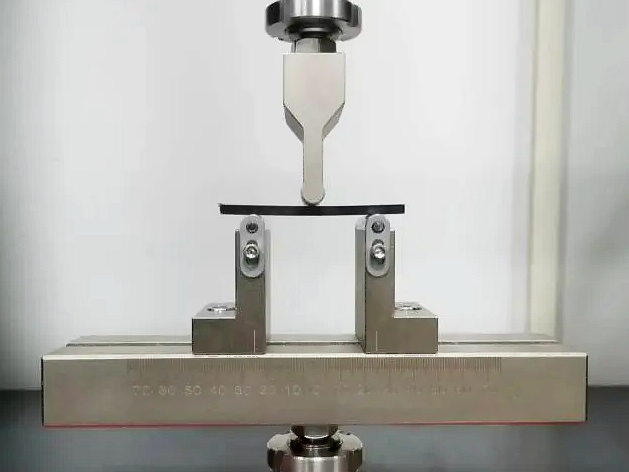

Typical Surface Treatment for Casting Tool and Die

Typical surface treatments for casting tools and dies include nitriding, PVD coating, electroplating, shot peening, polishing, and hard coating. These treatments enhance the hardness, wear resistance, corrosion resistance, and overall performance of the tool or die, ensuring better lifespan and reliability in demanding manufacturing processes.

Let's Start A New Project Today