Tumbling Service For Die Castings

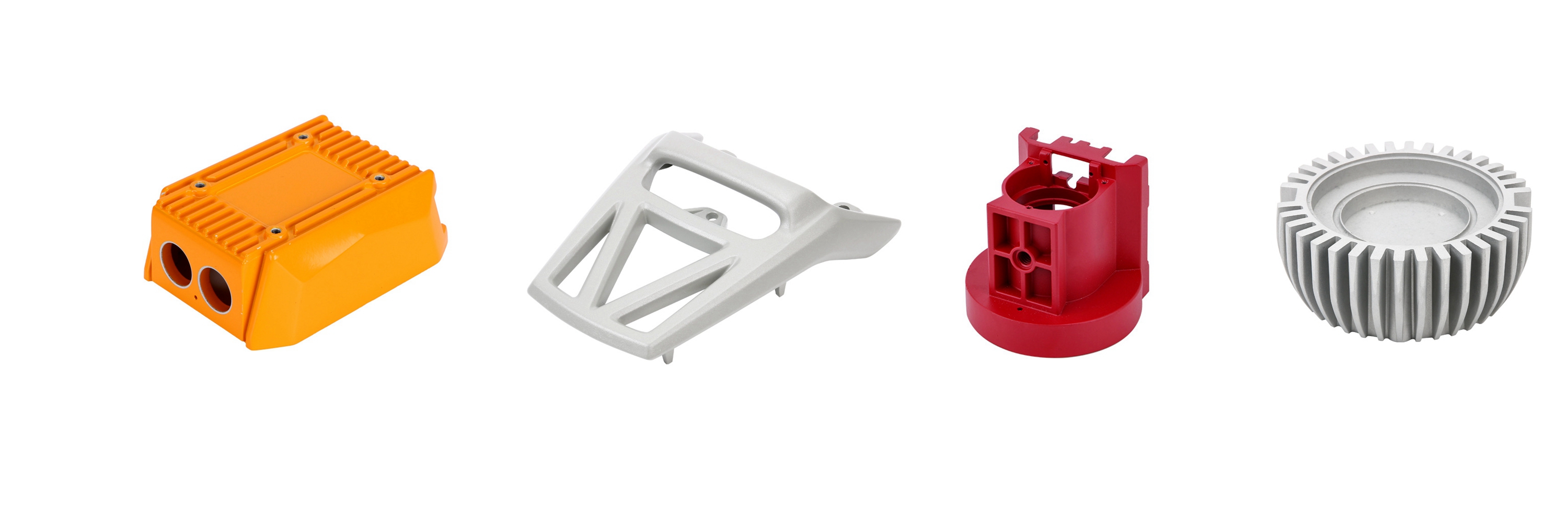

Tumbling Service for die castings involves using abrasive media to polish, smooth, and clean die-cast parts. It removes burrs, sharp edges, and contaminants while improving surface appearance, ensuring components are prepared for further processing, coating, or assembly.

- Surface Smoothing: Removes roughness for improved finish.

- Deburring: Eliminates sharp edges and burrs.

- Improved Aesthetics: Enhances appearance with consistent texture.

- Cleaning: Removes contaminants for better processing.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

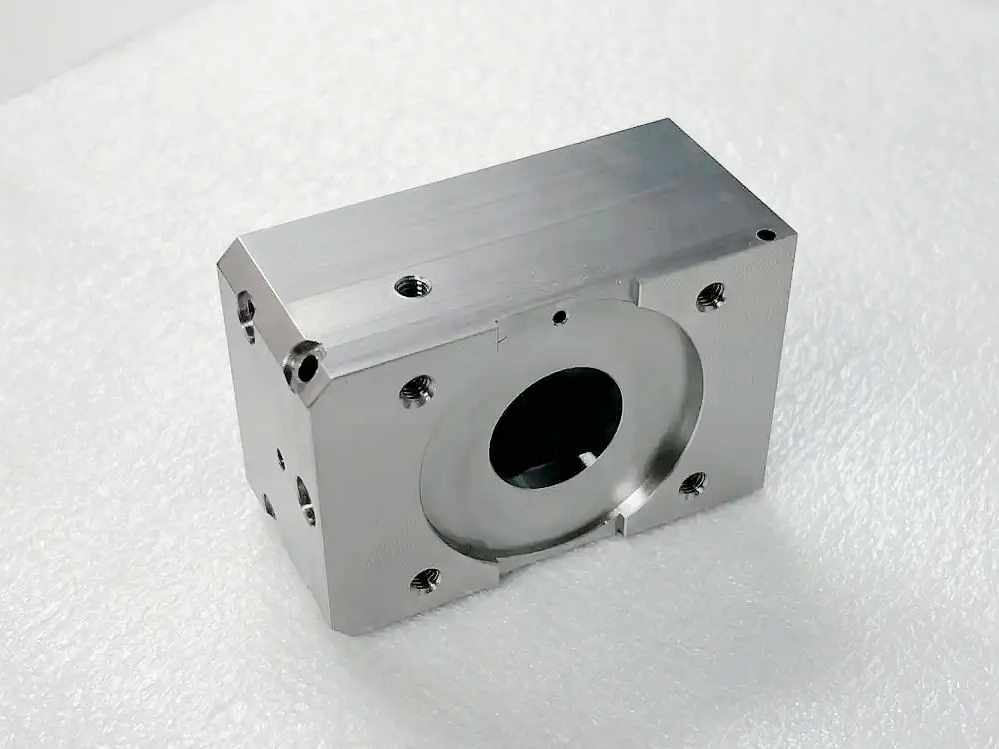

What Is Tumbling Service For Die Castings

Tumbling Service for die castings is a process where abrasive media is used to smooth, clean, and polish die-cast parts. It removes burrs, sharp edges, and contaminants, enhancing surface finish and preparing parts for further processing, coating, or assembly.

Properties of Tumbling

Tumbling is a post-processing method used for deburring, polishing, and smoothing parts made of metals, plastics, ceramics, and composites. It creates a smooth surface finish (Ra 0.4 - 3.2 µm) and enhances wear and corrosion resistance. It’s cost-effective, with moderate processing time, and is widely used in industries requiring surface cleaning, edge radiusing, and preparation for coatings.

Let's Start A New Project Today