Custom Online Urethane Casting Prototyping Service

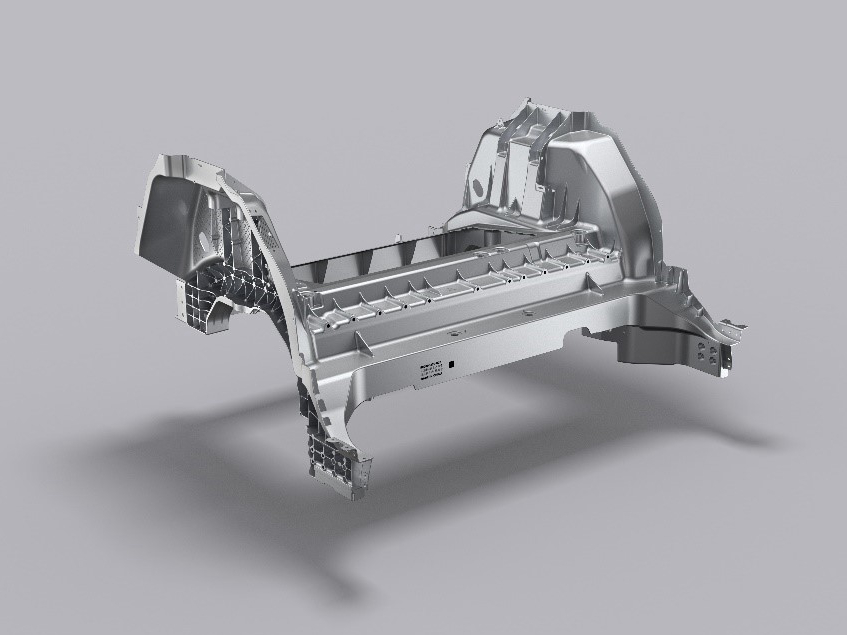

Our Custom Online Zinc Die Casting Service offers high-quality, precision castings with rapid prototyping, efficient post-processing, and a wide range of casting materials. We provide tailored solutions for various industries, ensuring fast turnaround and cost-effective manufacturing.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

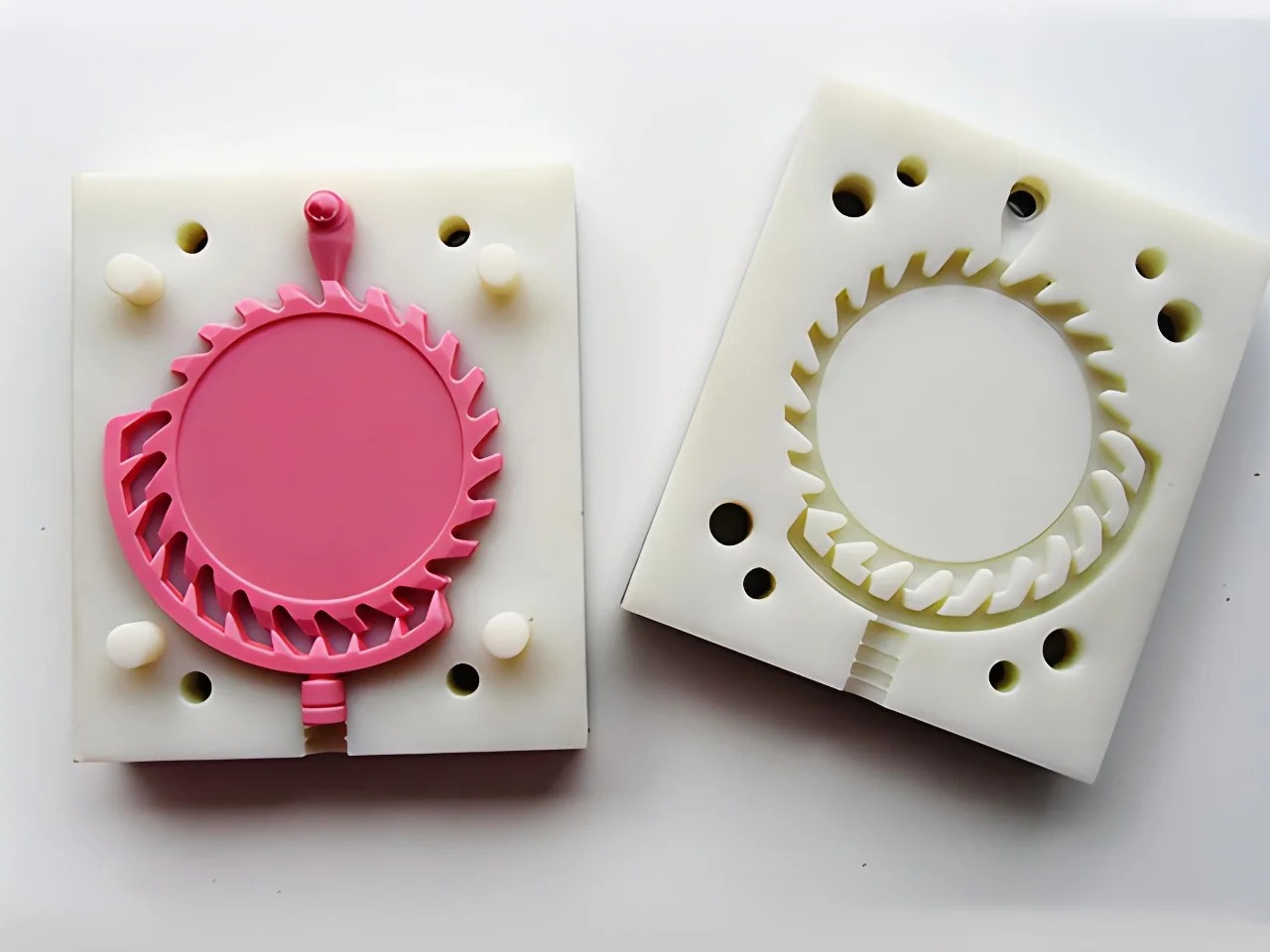

What Is Urethane Casting Prototyping?

Urethane casting prototyping is a rapid manufacturing process that creates durable and detailed parts from urethane resin. It involves creating a silicone mold from a master pattern and pouring the resin into it to produce accurate prototypes with excellent surface finish.

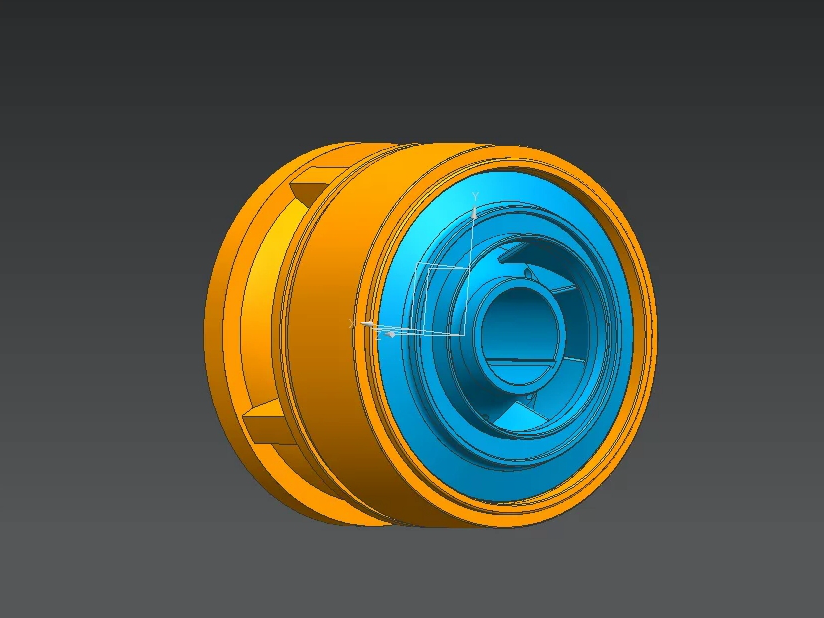

Benefits of Urethane Casting Prototyping

Urethane casting prototyping offers numerous advantages, including cost-effectiveness for low-volume production, high precision, material versatility, and faster production cycles. It’s an ideal solution for creating functional prototypes with complex geometries, ensuring quality while reducing time and costs for testing and iteration.

Let's Start A New Project Today