Custom Online Zinc Zamak Die Casting Service

Our Custom Online Zinc Die Casting Service offers high-quality, precision castings with rapid prototyping, efficient post-processing, and a wide range of casting materials. We provide tailored solutions for various industries, ensuring fast turnaround and cost-effective manufacturing.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

What Is Zinc/Zamak Die Casting?

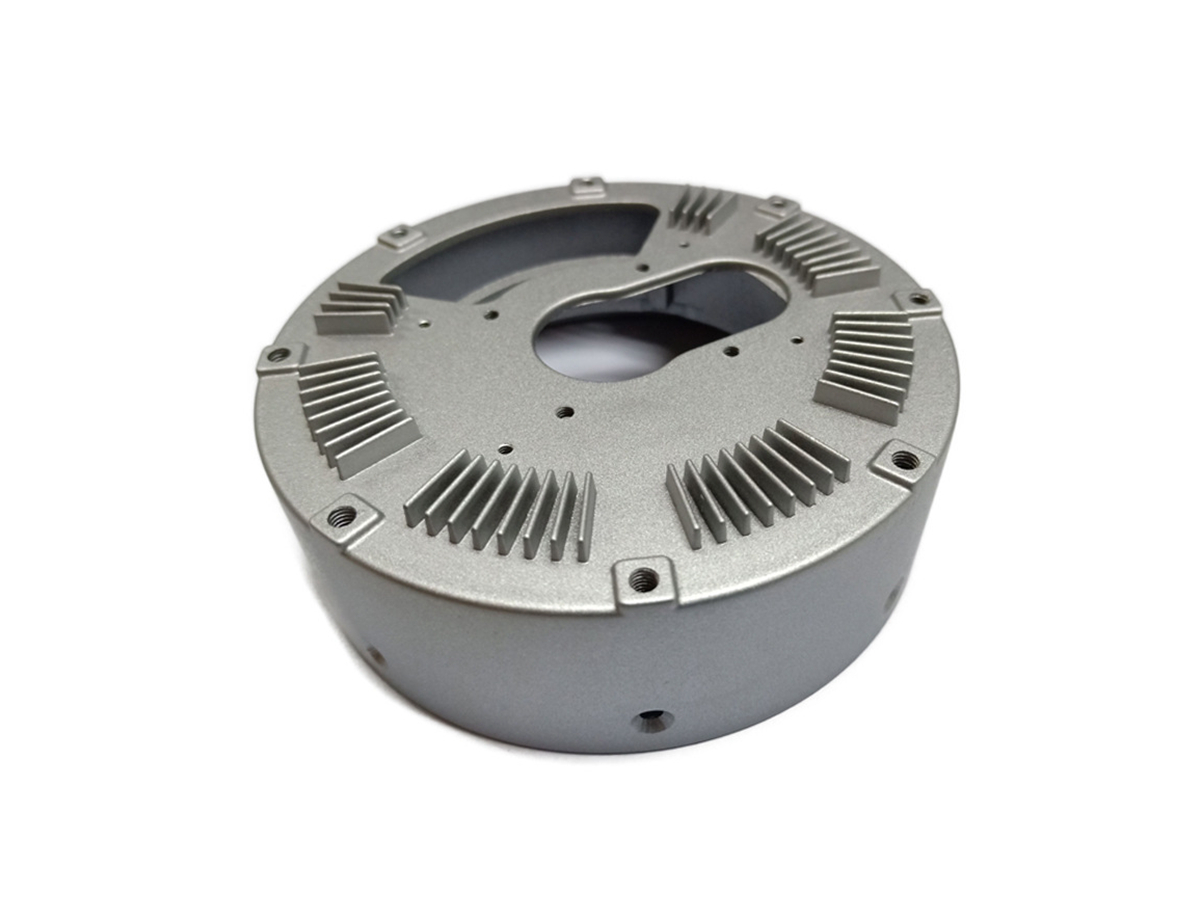

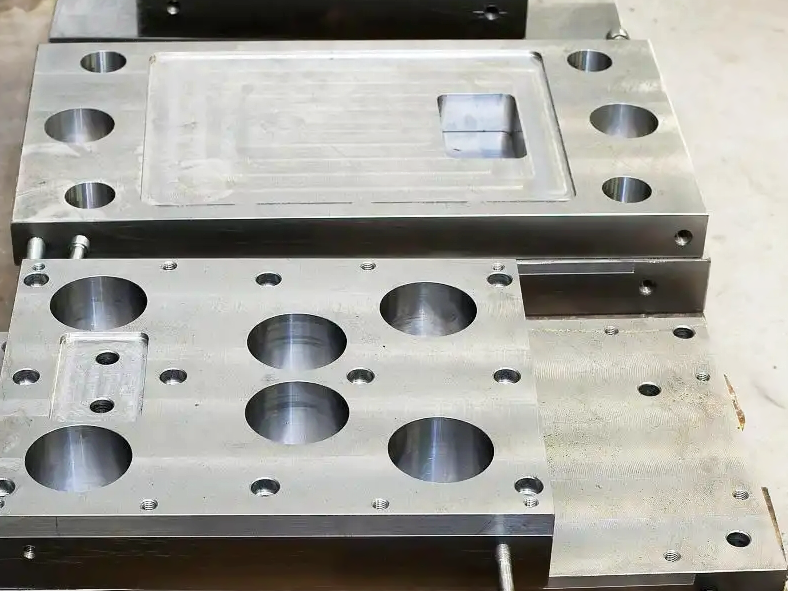

Zinc/Zamak die casting is a process where molten zinc alloy is injected into a mold under high pressure to create precise, durable parts. This method is ideal for producing complex shapes with excellent dimensional accuracy, strength, and surface finishes.

Benefits of Zinc/Zamak Die Castings

Aluminum die castings offer numerous benefits, including high dimensional accuracy, lightweight yet durable parts, design flexibility for complex geometries, and cost-effectiveness for mass production. These advantages make aluminum die casting ideal for industries like automotive, aerospace, and electronics.

Typical Casting Zinc/Zamak Alloys

We offer a range of high-quality aluminum alloys for die casting, including A356, A360, A380, ADC12 (A383), B390, A413, and anodized aluminum. Each alloy provides unique properties suited for various industries like automotive, aerospace, and electronics.

Typical Surface Treatment for Zinc Die Castings

Typical surface treatments for zinc die castings include chromate conversion coating, powder coating, electroplating, painting, polishing, shot blasting, vibratory finishing, chemical etching, clear coating, and PVD. These processes enhance properties such as corrosion resistance, surface hardness, appearance, and strength, while also improving durability and performance in various industrial applications.

Applications of Zamak Die Castings

Zamak die casting offers precision, durability, and cost-effective solutions across industries. Ideal for automotive door handles, corrosion-resistant electrical connectors, and consumer electronics casings, it ensures strength and intricate detailing. From secure lock mechanisms to fashion accessories, medical device housings, and industrial machinery parts, Zamak die casting enhances performance and reliability.

Let's Start A New Project Today

Zinc Die Castings Design

Good design in zinc die castings offers enhanced strength, improved surface finish, and reduced porosity. It ensures optimal metal flow, uniform wall thickness, and precise dimensions, minimizing defects and improving part durability. Efficient design also reduces material waste, lowers production costs, and shortens lead times, ultimately improving the quality, functionality, and cost-effectiveness of the final product.