Design Capabilities At Neway

Online Custom Component Design Service

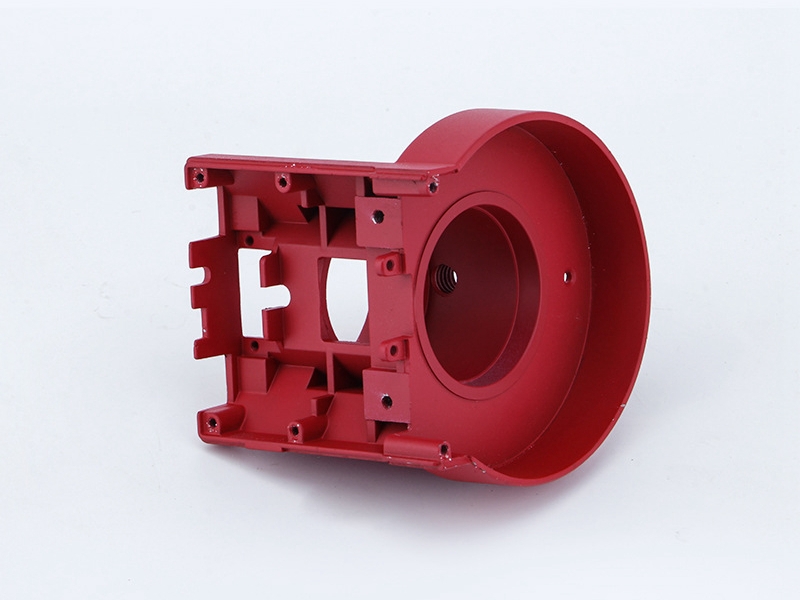

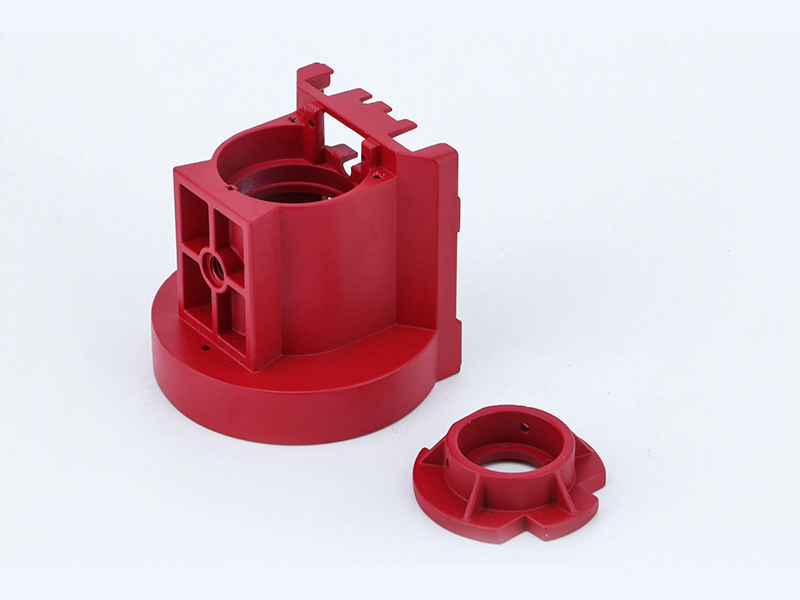

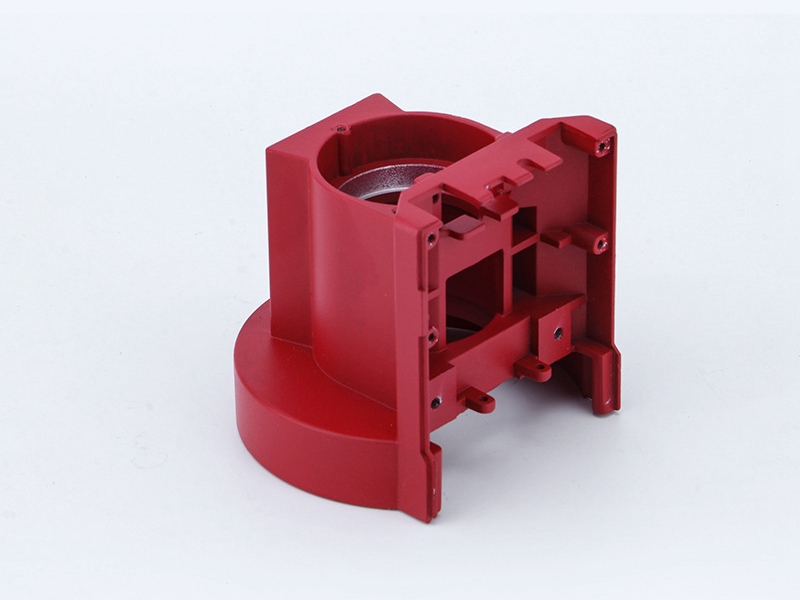

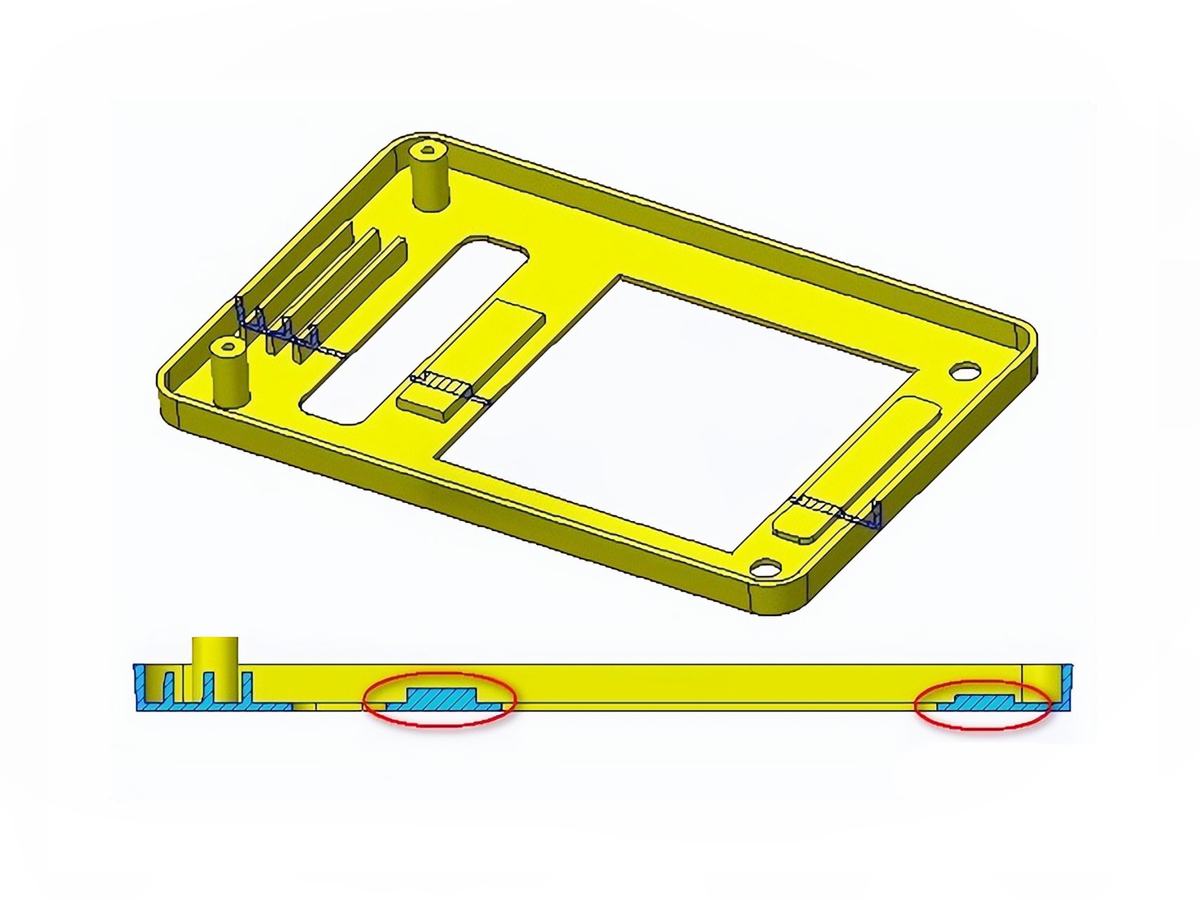

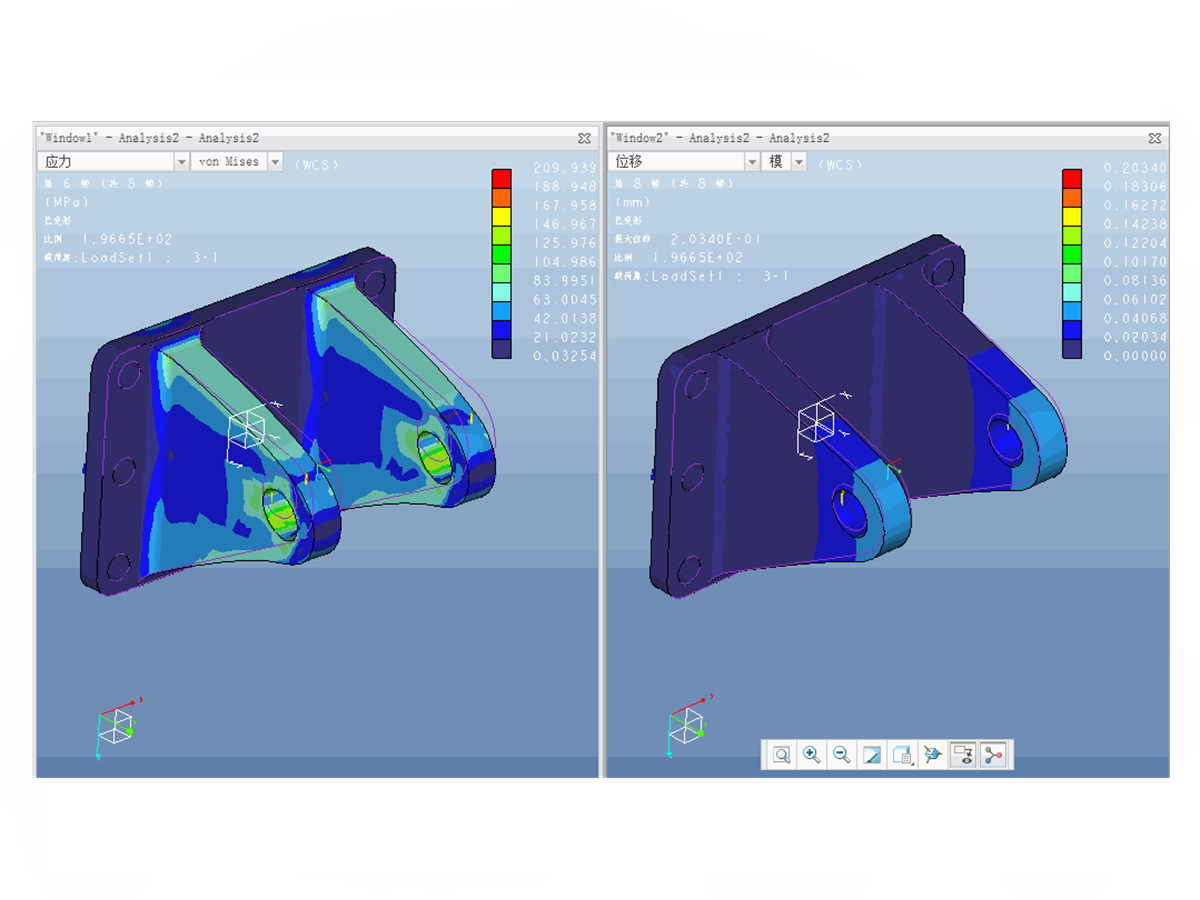

At Neway, we specialize in Die Casting Component Design, offering tailored solutions that optimize functionality, performance, and manufacturability. Our expert team provides 3D modeling, design optimization, and rapid prototyping to ensure precise, cost-effective, and high-quality die-cast components.

Main Manufacturing Casting Services

We specialize in custom parts design for Aluminum Die Casting, Zinc Die Casting, Copper Die Casting, and Tool and Die Making. Our expert team delivers precision-engineered components tailored to your industry needs, ensuring high-quality, durable, and efficient manufacturing solutions. From concept to production, we provide innovative designs to enhance performance and optimize cost-effectiveness for your projects.

Rapid Prototyping Services

We provide high-quality rapid prototyping solutions, including CNC Machining, 3D Printing, Urethane Casting, and Sand Casting. Our advanced manufacturing techniques ensure fast turnaround, precision, and cost-efficiency, enabling product testing, design validation, and seamless transition to mass production.

Post Process Services

We offer Sand Blasting, Post Machining, Tumbling, Assembling, Painting, Powder Coating, Anodizing, and Arc Anodizing to enhance durability, aesthetics, and functionality.

Casting Material Selection & Optimization

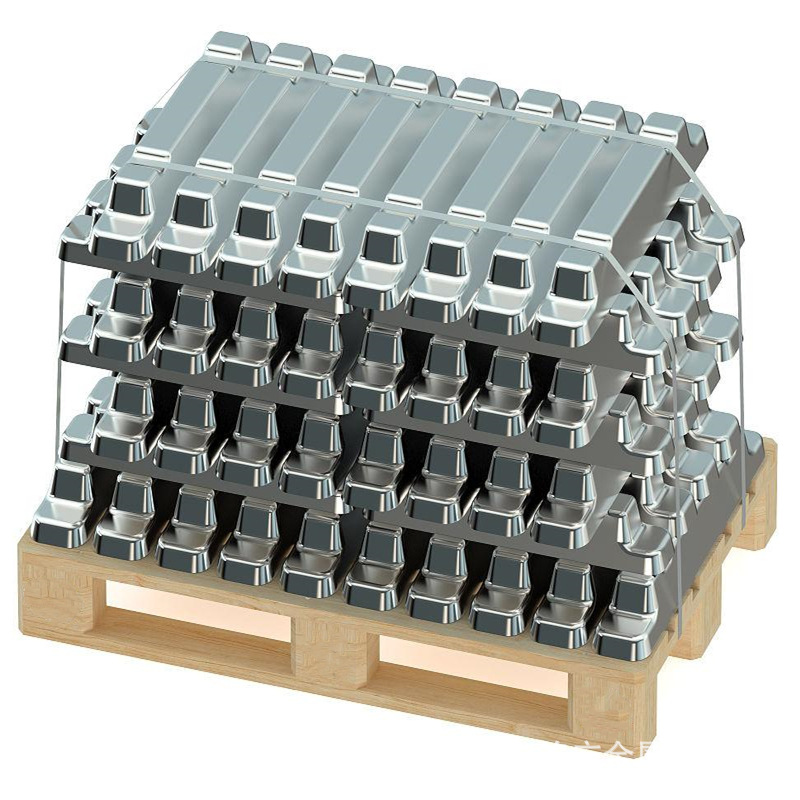

We offer expert guidance in material selection and optimization for die casting and tooling applications. Our material solutions ensure superior mechanical properties, durability, and performance tailored to industry-specific requirements, helping to enhance product quality and cost-effectiveness.

Let's Start A New Project Today