Low Volume Manufacturing Capabilities At Neway

Custom Parts Low Volume Manufacturing Service

Neway’s Custom Parts Low Volume Manufacturing Service delivers high-quality, precision-engineered components with fast turnaround times. We specialize in flexible production runs, offering CNC machining, prototyping, and material selection to meet your unique needs while ensuring cost-efficiency and reliability.

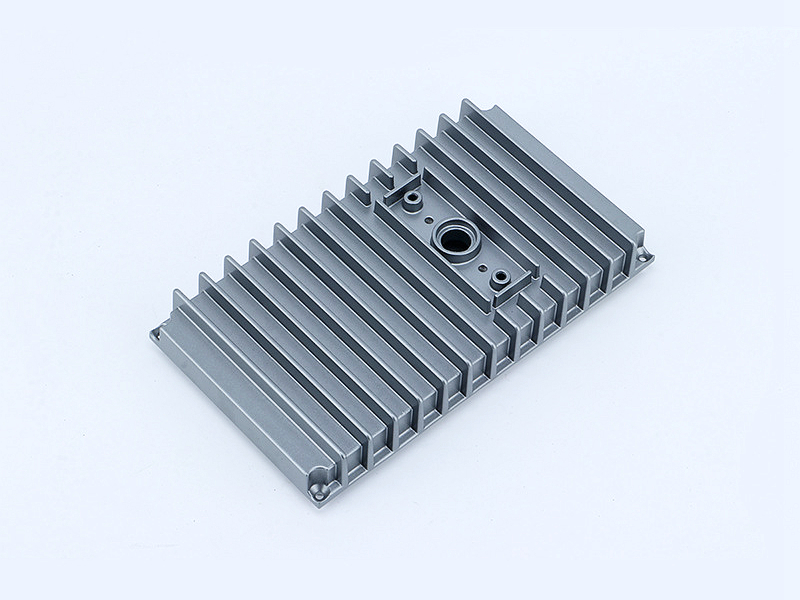

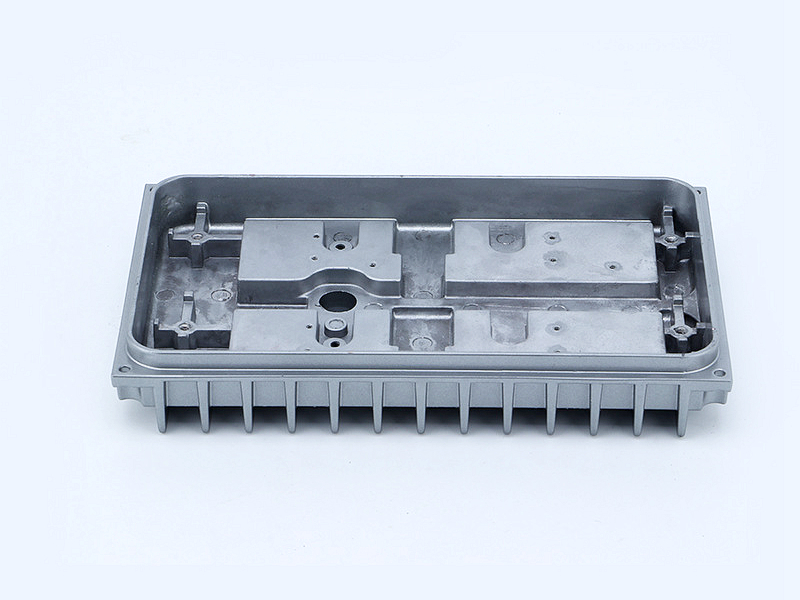

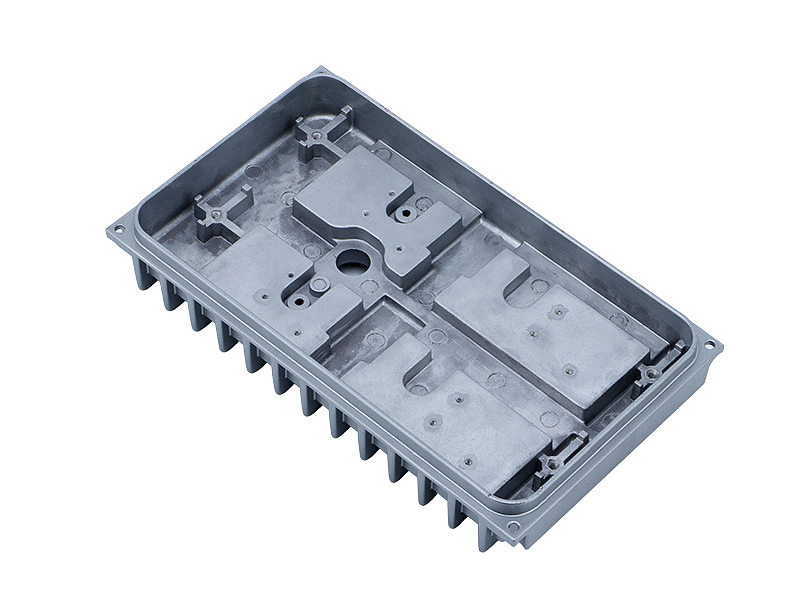

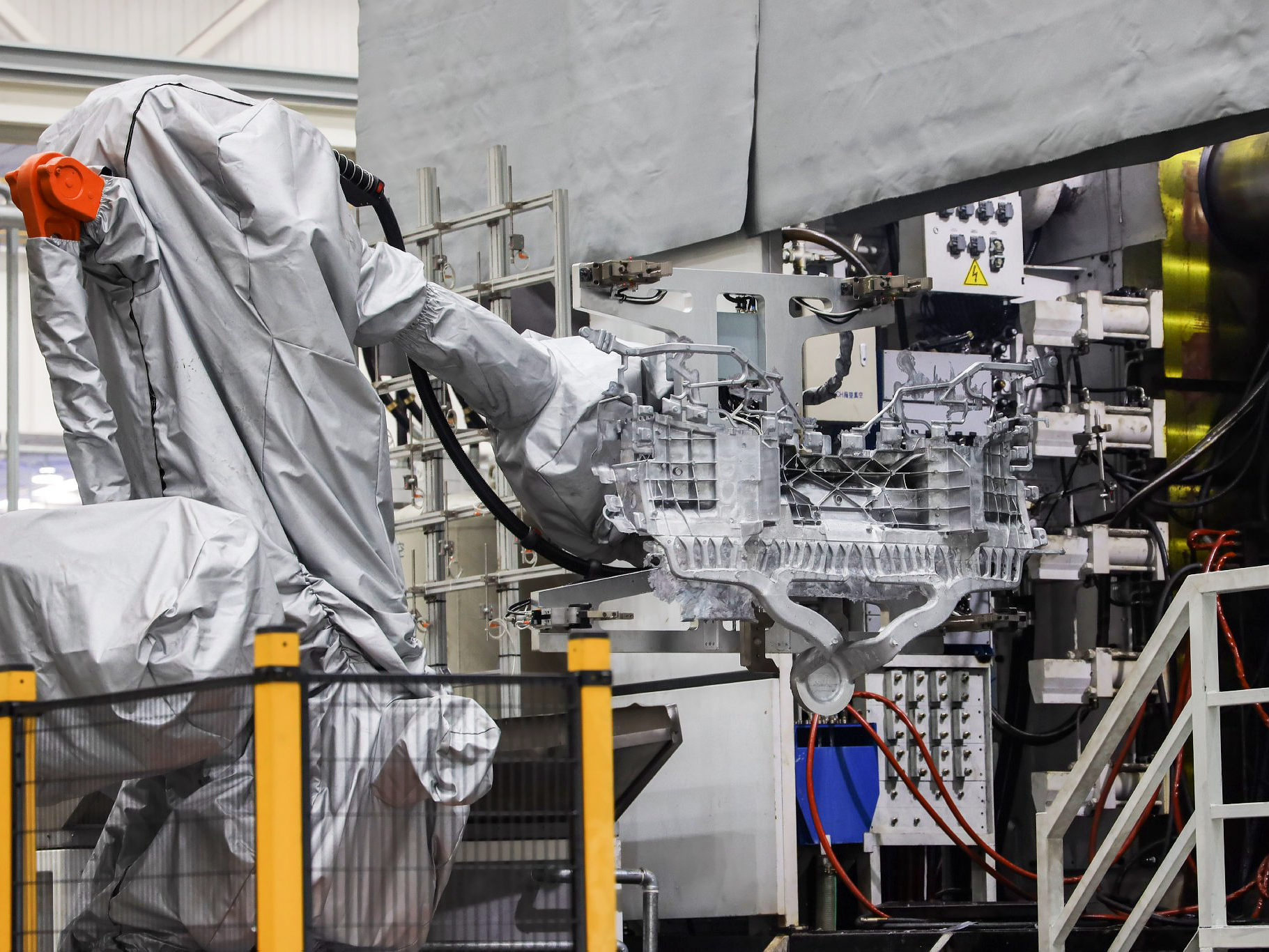

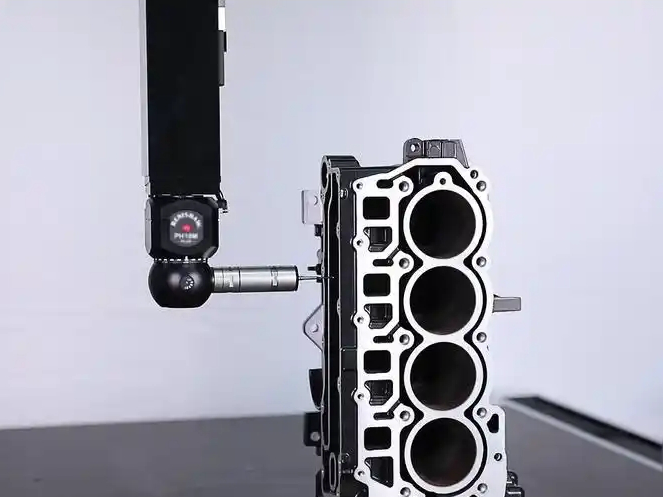

Metal Casting - Low Volume Manufacturing

We provide custom parts low-volume manufacturing services, specializing in CNC machining, small-batch die casting, flexible tooling, and quick turnaround solutions. Our expertise ensures high-quality, cost-effective production for customized components with rapid delivery for urgent orders.

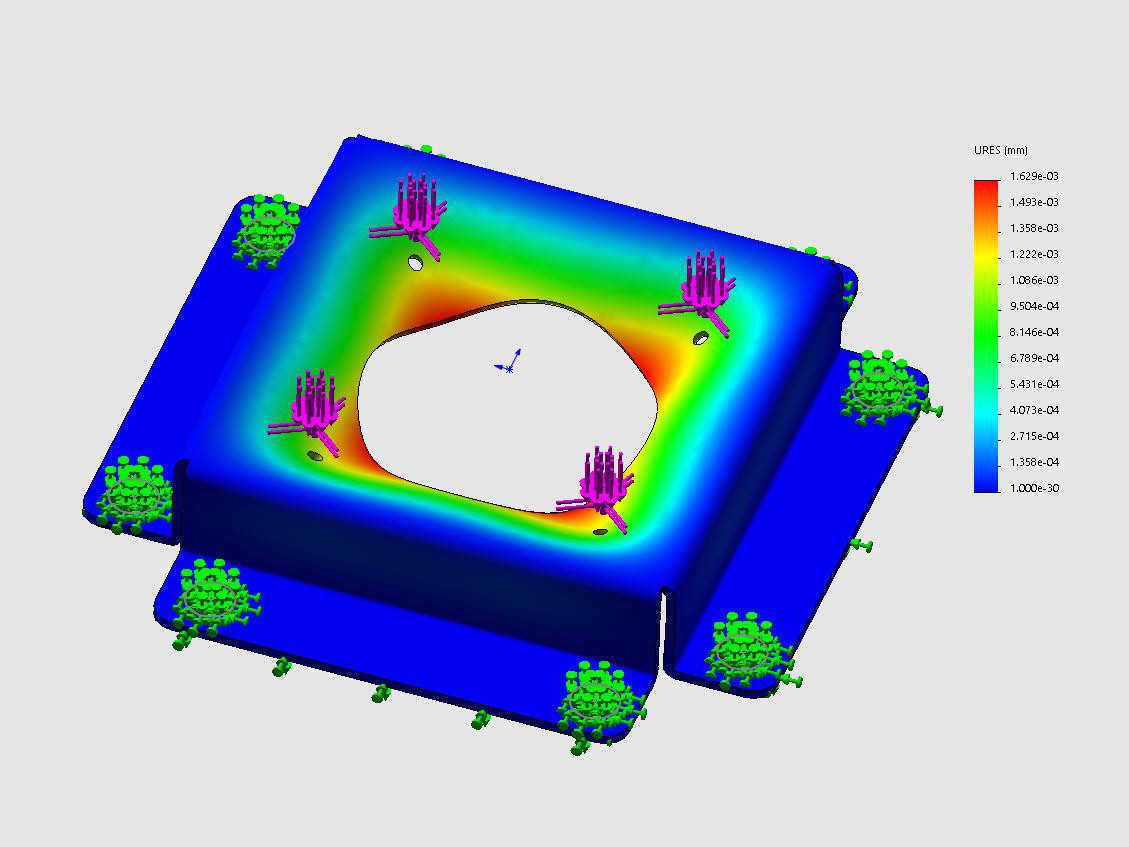

Rapid Prototyping - Low Volume Manufacturing

We specialize in custom parts low-volume manufacturing through rapid prototyping, CNC machining, small-batch die casting, and flexible tooling solutions. Our services ensure quick turnaround, cost-effective production, and high-quality customized components for various industries.

Post Process - Low Volume Manufacturing

We provide high-quality post-processing solutions for low-volume manufacturing, including machining, surface finishing, coating, and assembly. Our services ensure enhanced durability, aesthetics, and functionality for CNC-machined and die-cast components with quick turnaround times.

Casting Material - Low Volume Manufacturing

We specialize in custom parts low-volume manufacturing with expert material selection, including Aluminum Alloys, Zinc Alloys, Copper Alloys, and Tool Materials. Our flexible tooling and rapid production ensure high-quality, cost-effective solutions for small-batch and short-run manufacturing.

Let's Start A New Project Today