Mass Production Capabilities At Neway

Online Custom Parts Mass Production Service

Neway’s Online Custom Parts Mass Production Service offers efficient, scalable solutions for high-volume manufacturing. With precise engineering, streamlined ordering, and rigorous quality control, we ensure cost-effective production, fast lead times, and consistent results for your custom part needs.

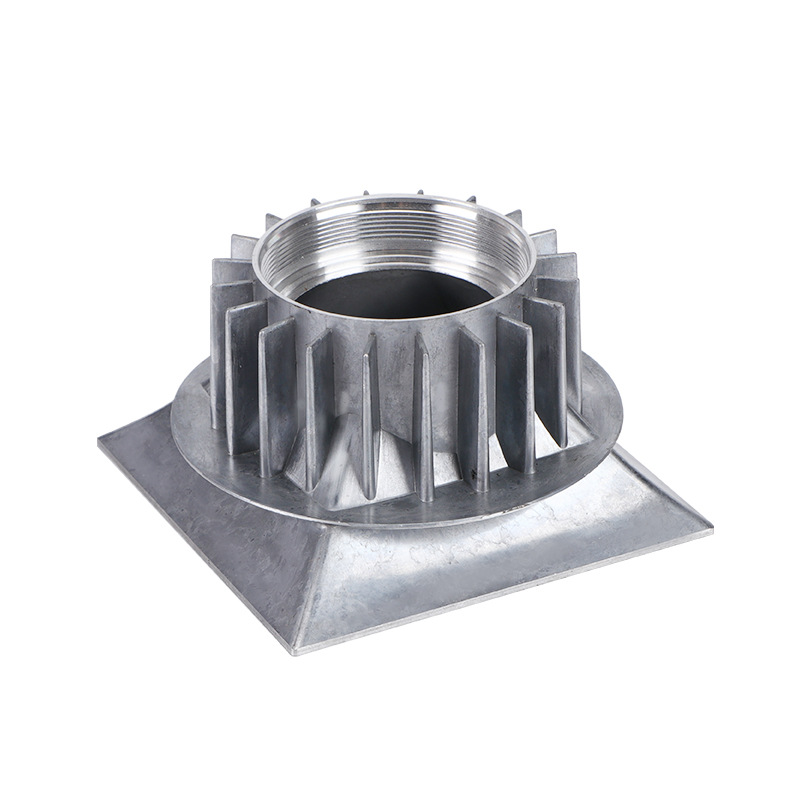

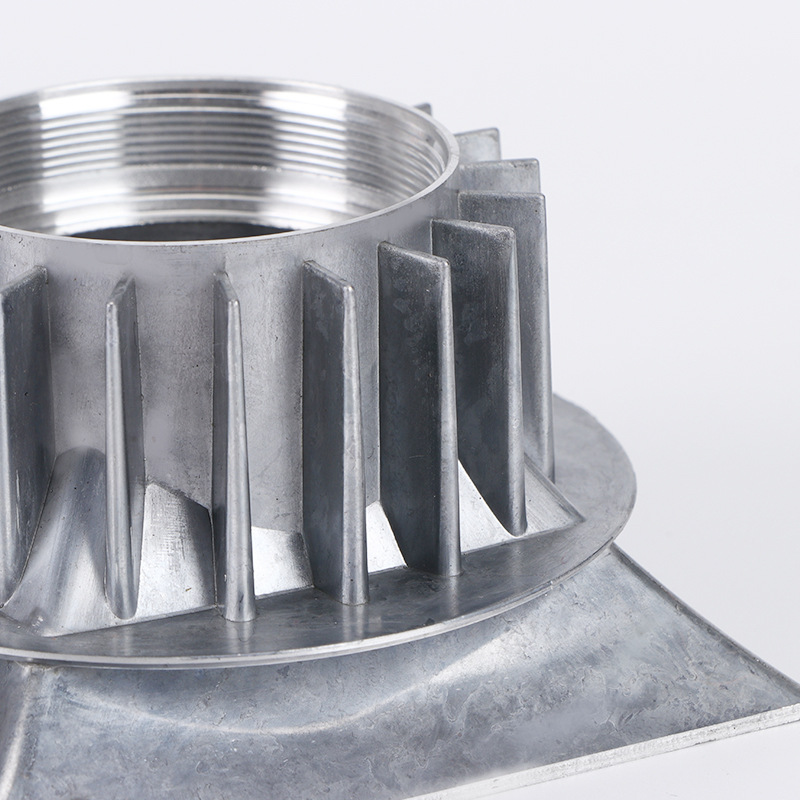

Metal Casting - Mass Production Services

We specialize in online custom parts mass production with high-volume die casting, precision machining, automated production lines, and strict quality control. Our cost-efficient solutions ensure consistent, high-quality components for bulk manufacturing in various industries.

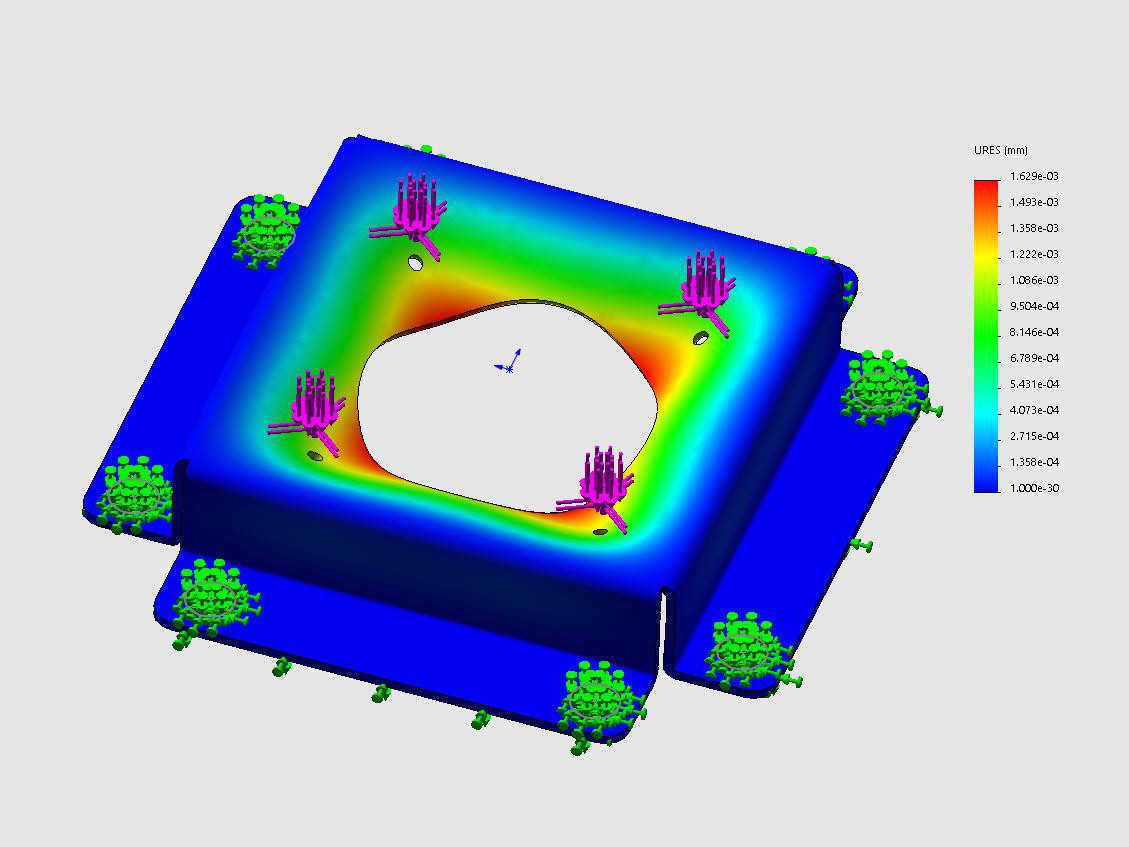

Rapid Prototyping - Mass Production Services

We provide advanced rapid prototyping solutions to support mass production, ensuring high-precision, cost-efficient, and scalable manufacturing. Our services include CNC machining, 3D printing, urethane casting, and sand casting for quick iteration and pre-production validation.

Post Process - Mass Production Services

We offer advanced post-processing solutions for high-volume manufacturing, ensuring quality, durability, and consistency through machining, finishing, and coating processes.

Casting Material - Mass Production Services

We specialize in high-volume manufacturing with precise material selection, ensuring quality, durability, and consistency for mass production. Our expertise in Aluminum Alloys, Zinc Alloys, Copper Alloys, and Tool Materials guarantees cost-efficient and scalable bulk manufacturing.

Let's Start A New Project Today