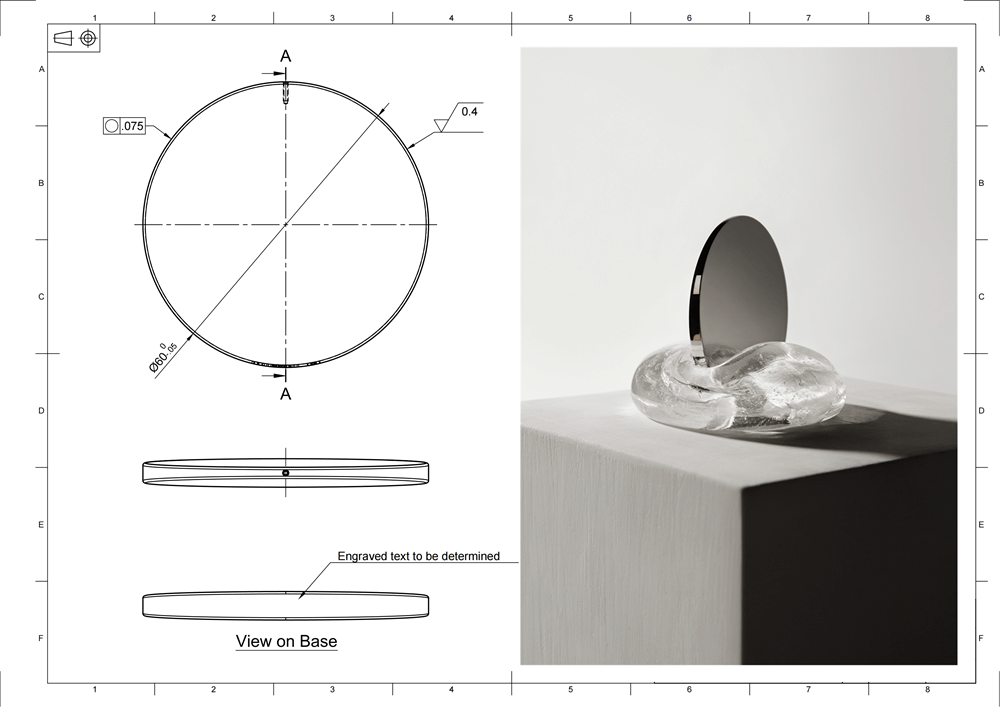

Adamonyte-Keidune Zamak Parts Casting and PVD Coating Mirror Manufacturing

Introduction

Adamonyte-Keidune, a leader in premium mirror designs, collaborated with Neway to produce precision mirror components using Zamak alloy casting. Integrating advanced die casting processes with innovative PVD coating, the partnership achieved exceptional surface finishes and dimensional accuracy.

Neway's expertise delivered mirror-quality components meeting stringent aesthetic and performance standards essential for Adamonyte-Keidune’s luxury decorative products.

Project Background and Customer Requirements

Adamonyte-Keidune specializes in premium decorative and functional mirrors, requiring mirror components that blend precision, aesthetics, and durability. The customer required Zamak cast parts with flawless surface finishes, precise dimensional accuracy, corrosion resistance, and high reflectivity suitable for luxury interior installations.

Key customer requirements included:

Requirement | Industry Specification |

|---|---|

Dimensional accuracy | ±0.03 mm tolerance (ISO 2768-f) |

Surface finish | Mirror-level surface quality Ra ≤0.8 µm |

Corrosion resistance | Salt-spray tested ≥240 hours (ASTM B117) |

Reflective coating durability | PVD coating adherence (ISO 2409 Class 0) |

Quality compliance | Adamonyte-Keidune’s internal QC standards |

Why Choose Zamak for Mirror Components?

Zamak (Zinc alloy) was specifically selected for manufacturing Adamonyte-Keidune mirror components due to its superior casting properties, detailed surface finish, and excellent mechanical characteristics:

Precision Castability: Zamak achieves intricate details and thin walls (down to 0.8 mm), ideal for decorative mirror frames and mountings.

Superior Surface Quality: Allows for extremely smooth surfaces, typically achieving Ra ≤0.8 µm without secondary polishing.

High Mechanical Strength: Offers tensile strengths between 280-380 MPa, providing robust durability for decorative fixtures.

Corrosion Resistance: Enhanced durability against corrosion, particularly when combined with high-quality coatings such as PVD.

Specifically, Zamak 3 alloy was chosen for its balanced combination of castability, dimensional stability, and mechanical strength.

Die Casting and PVD Coating Process Solutions

Neway provided Adamonyte-Keidune with an integrated production solution combining precision Zamak die casting with advanced PVD coating processes:

Precision Tool and Die Design

Using advanced CAD software and flow simulation (AutoDesk Moldflow), Neway engineered precision dies from high-quality H13 steel, heat-treated to 46-48 HRC. The robust tooling design ensured minimal dimensional variance (±0.02 mm) and longevity of over 150,000 casting cycles.

High-Pressure Zamak Die Casting

Employing state-of-the-art zinc die casting equipment, Neway maintained precise casting parameters, including injection pressures of 30-70 MPa and alloy melt temperatures of 400-430°C. Real-time quality monitoring and controlled cooling systems delivered components with porosity levels consistently below 0.1%.

Advanced PVD Coating Process

The mirror components underwent advanced Physical Vapor Deposition (PVD) coating, delivering superior reflective properties and outstanding resistance to scratches and corrosion. The PVD coating process adhered strictly to ISO standards, providing uniform film thickness (0.5-1.5 µm) and unmatched durability (ISO 2409 adhesion test Class 0).

Project Outcomes and Benefits Delivered

The successful partnership delivered significant measurable benefits to Adamonyte-Keidune:

Premium Surface Finish: Achieved mirror-level surface finishes consistently below Ra 0.8 µm, directly enhancing product aesthetics and value.

Outstanding Corrosion Resistance: Components passed rigorous ASTM B117 salt-spray tests, sustaining over 240 hours without signs of corrosion.

Dimensional Accuracy: Maintained exceptional dimensional consistency, with all parts within ±0.03 mm tolerance range, surpassing decorative industry benchmarks.

Enhanced Product Durability: High-quality PVD coatings significantly improved scratch resistance, prolonging the lifespan of the mirror components by 25%.

Challenges and Solutions

Throughout the Zamak casting and PVD coating processes, key challenges addressed by Neway included:

Surface Imperfections: Precision-controlled die temperatures and casting parameters ensured defect-free surfaces, eliminating common imperfections (cold shuts, flow lines) below 0.5%.

Adherence of PVD Coating: Rigorous surface cleaning and preparation ensured optimal coating adhesion, meeting ISO 2409 Class 0 standard consistently.

Dimensional Precision Maintenance: Consistent tooling maintenance schedules and quality monitoring preserved strict dimensional accuracy within ±0.03 mm throughout extended production runs.

Why Adamonyte-Keidune Selected Neway

Adamonyte-Keidune chose Neway as their manufacturing partner for several decisive factors:

Extensive Decorative Casting Experience: Demonstrated track record of producing premium-grade decorative zinc castings for luxury applications.

Advanced Coating Capabilities: Expertise in integrating precision die casting with advanced surface finishing processes, notably high-quality PVD coatings.

Quality Assurance Standards: Strong quality control frameworks compliant with international standards (ISO 9001, ASTM standards).

Comprehensive Manufacturing Services: Complete, streamlined one-stop manufacturing solutions from initial design and tooling to finishing and coating.

Conclusion and Future Collaboration

The Adamonyte-Keidune Zamak casting and PVD mirror manufacturing project showcased Neway’s capability to deliver premium-quality components suitable for high-end applications. The successful execution of this project reinforced Adamonyte-Keidune’s confidence in Neway as a reliable partner, laying a solid foundation for ongoing collaboration in luxury decorative manufacturing.

FAQs Buyers Usually Concern:

What tolerances can be reliably achieved with Zamak die casting?

How durable are PVD-coated mirror surfaces in decorative applications?

Which Zamak alloy is best suited for decorative mirror manufacturing?

How does Neway ensure coating consistency and adhesion?

What is the typical lead time for Zamak casting projects?