Inspection And Quality Assurance

Custom Parts Testing and Quality Assurance

Neway’s Custom Parts Testing and Quality Assurance service ensures every component meets the highest standards of performance and durability. Through rigorous testing and thorough inspection processes, we verify dimensional accuracy, material integrity, and functional reliability to deliver flawless, high-quality parts.

Coordinate Measuring Machine (CMM)

A Coordinate Measuring Machine (CMM) ensures custom parts' quality by precisely measuring dimensions, geometries, and surface profiles against design specifications. It detects deviations, ensuring accuracy in die casting, CNC machining, and prototyping. CMM enhances consistency, reduces defects, and maintains tight tolerances, making it essential for high-precision copper-brass custom parts in manufacturing.

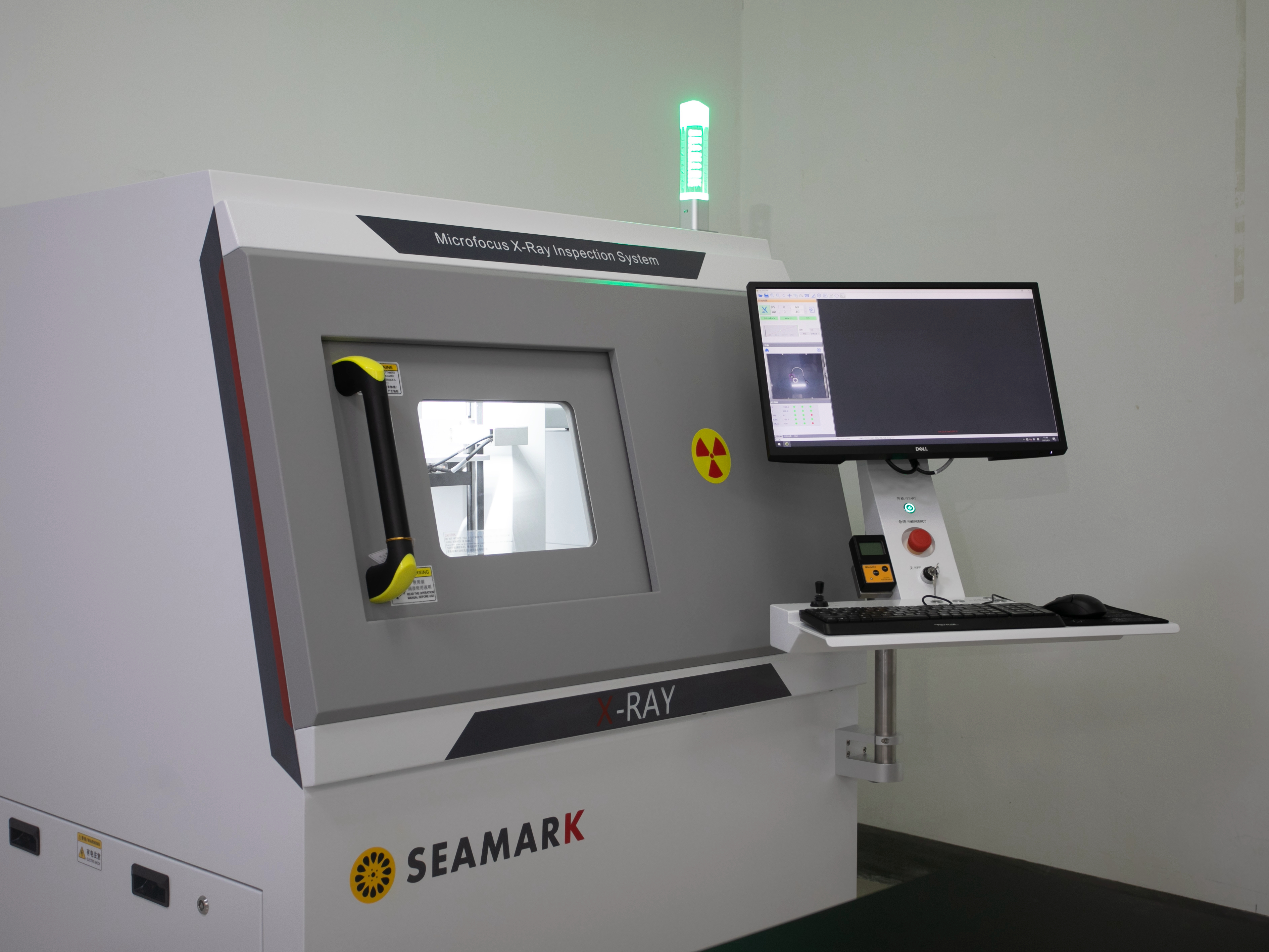

X-ray Inspection

X-ray Inspection is a non-destructive testing method that detects internal defects, porosity, cracks, and voids in custom metal parts. It ensures structural integrity, reliability, and compliance with quality standards in die casting, CNC machining, and precision manufacturing. By revealing hidden flaws, X-ray inspection enhances product safety and performance.

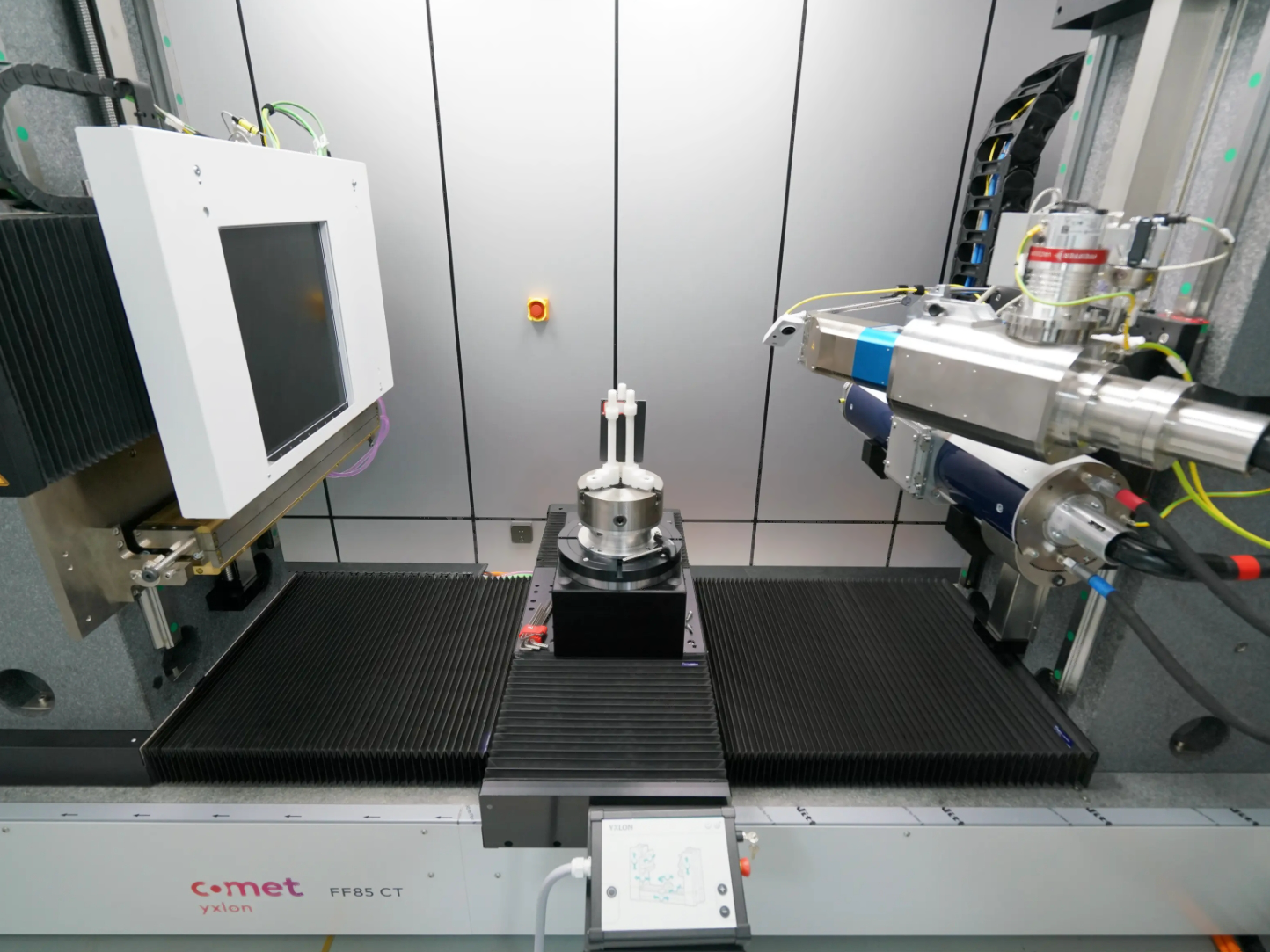

450KV Line Array Industrial CT

The 450KV Line Array Industrial CT is a high-powered imaging system used for precision quality assurance in custom metal parts. It provides detailed internal scans, detecting defects such as porosity, inclusions, and structural inconsistencies without damaging components. This advanced CT technology ensures accuracy, consistency, and reliability in die casting, CNC machining, and precision manufacturing.

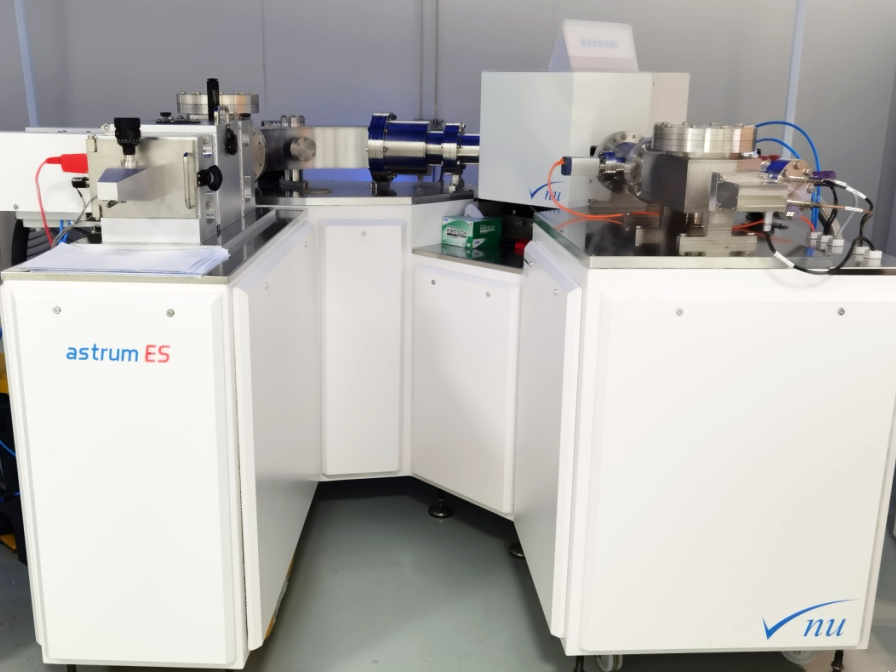

Glow Discharge Mass Spectrometer (GDMS)

The Glow Discharge Mass Spectrometer (GDMS) is a high-precision analytical tool for ultra-pure alloy verification in metal casting. It detects trace elements, impurities, and material composition with exceptional accuracy, ensuring superior quality control for die casting, CNC machining, and precision manufacturing applications.

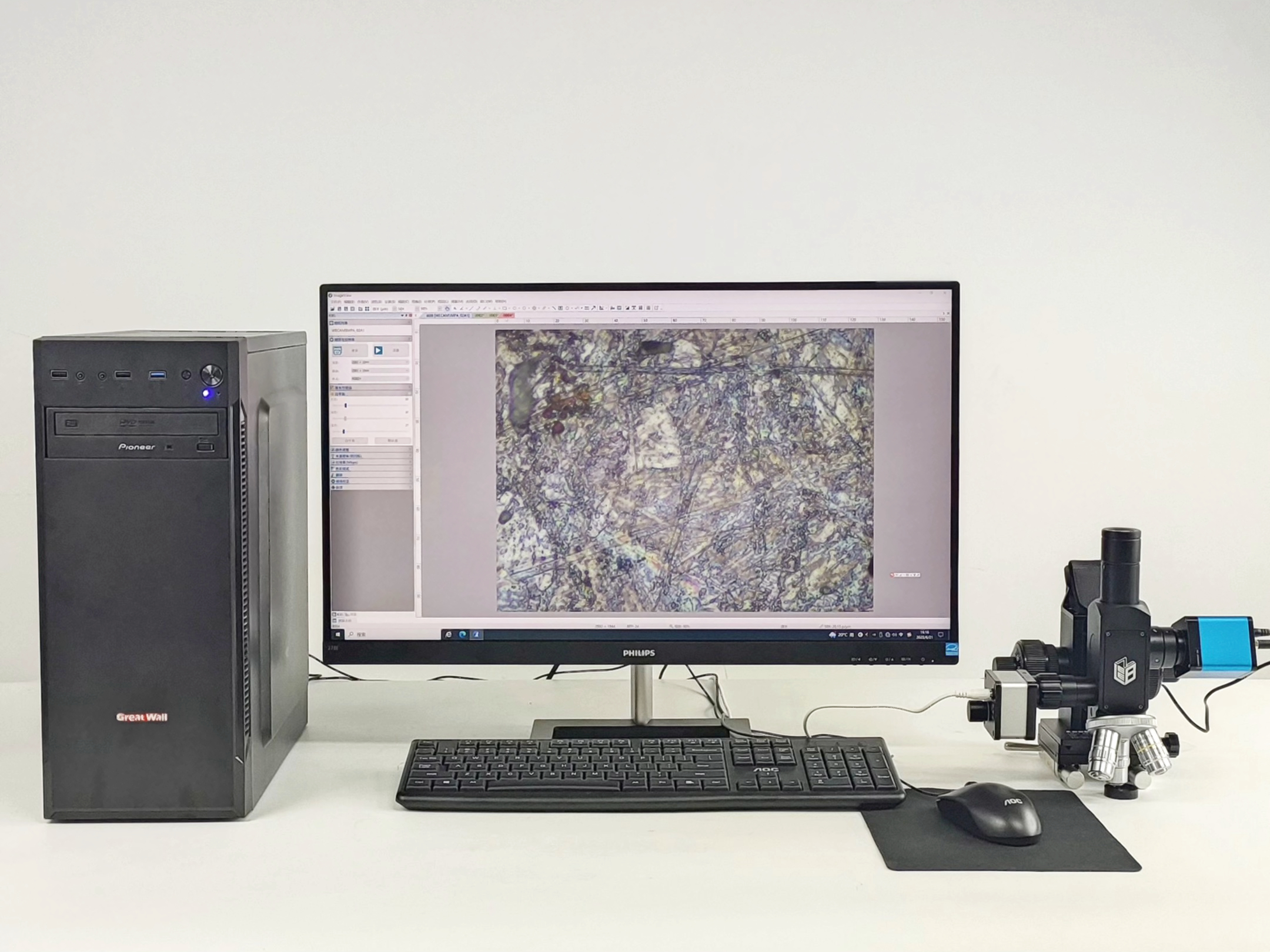

Metallographic Microscopy

Metallographic Microscopy is a crucial technique for analyzing the microstructure of custom metal components, ensuring defect-free manufacturing. It examines grain structure, phase distribution, and material consistency, identifying flaws that affect mechanical properties and performance in die casting, CNC machining, and precision manufacturing applications.

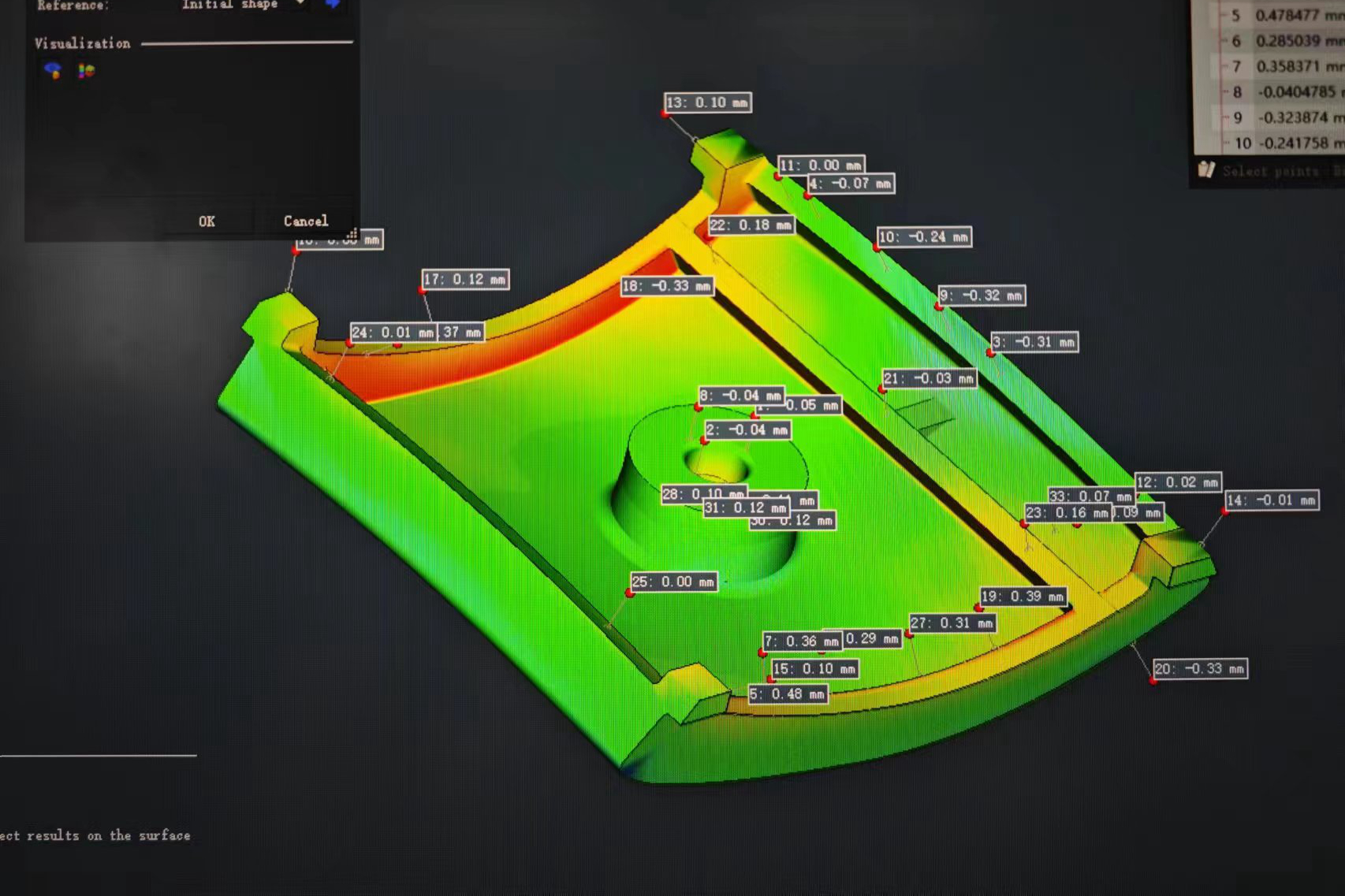

3D Scanning Measuring Instrument

3D Scanning Measuring Instrument technology enables high-precision measurements for custom manufacturing by capturing detailed part geometries with exceptional accuracy. It ensures dimensional integrity, detects deviations, and optimizes quality control in die casting, CNC machining, and rapid prototyping applications.

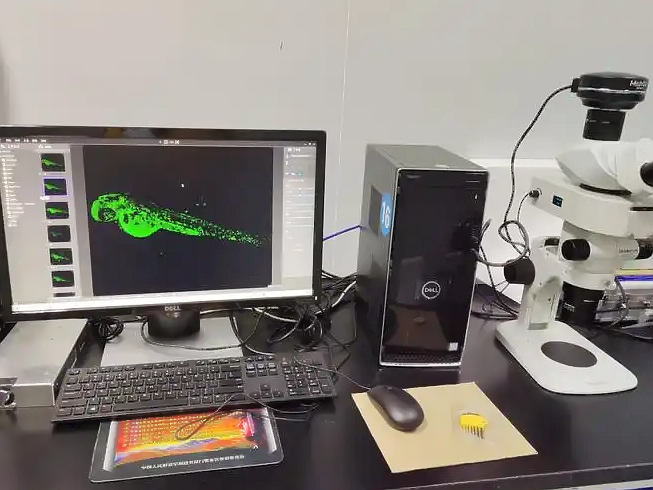

Stereo Microscope

The Stereo Microscope provides enhanced visual inspection for surface and structural analysis, offering detailed 3D imaging of custom-manufactured parts. It detects surface defects, verifies fine details, and ensures quality control in die casting, CNC machining, and precision manufacturing applications.

Scanning Electron Microscope (SEM)

The Scanning Electron Microscope (SEM) enables unrivaled surface analysis for microscopic defect detection in custom metal components. It provides high-magnification imaging, revealing microstructural inconsistencies, surface irregularities, and contamination, ensuring superior quality control in die casting, CNC machining, and precision manufacturing.

Direct Reading Spectrometer

The Direct Reading Spectrometer ensures accurate alloy composition analysis for consistent material quality in metal casting and machining. It quickly detects elemental composition, ensuring compliance with industry standards, reducing material defects, and enhancing quality control in high-precision manufacturing applications.

Let's Start A New Project Today